Polysulfone resin polymer material and preparation method thereof

A polymer material and polysulfone technology, applied in the field of polysulfone resin polymer materials and their preparation, can solve the problems of adverse effects on the product quality of polysulfone materials, affecting the storage and use of polysulfone materials, difficult to dissolve and remove, and the like, To achieve the effect of reducing the influence of cyclic dimer impurities, the preparation method is simple and convenient, and reducing the content of cyclic dimer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

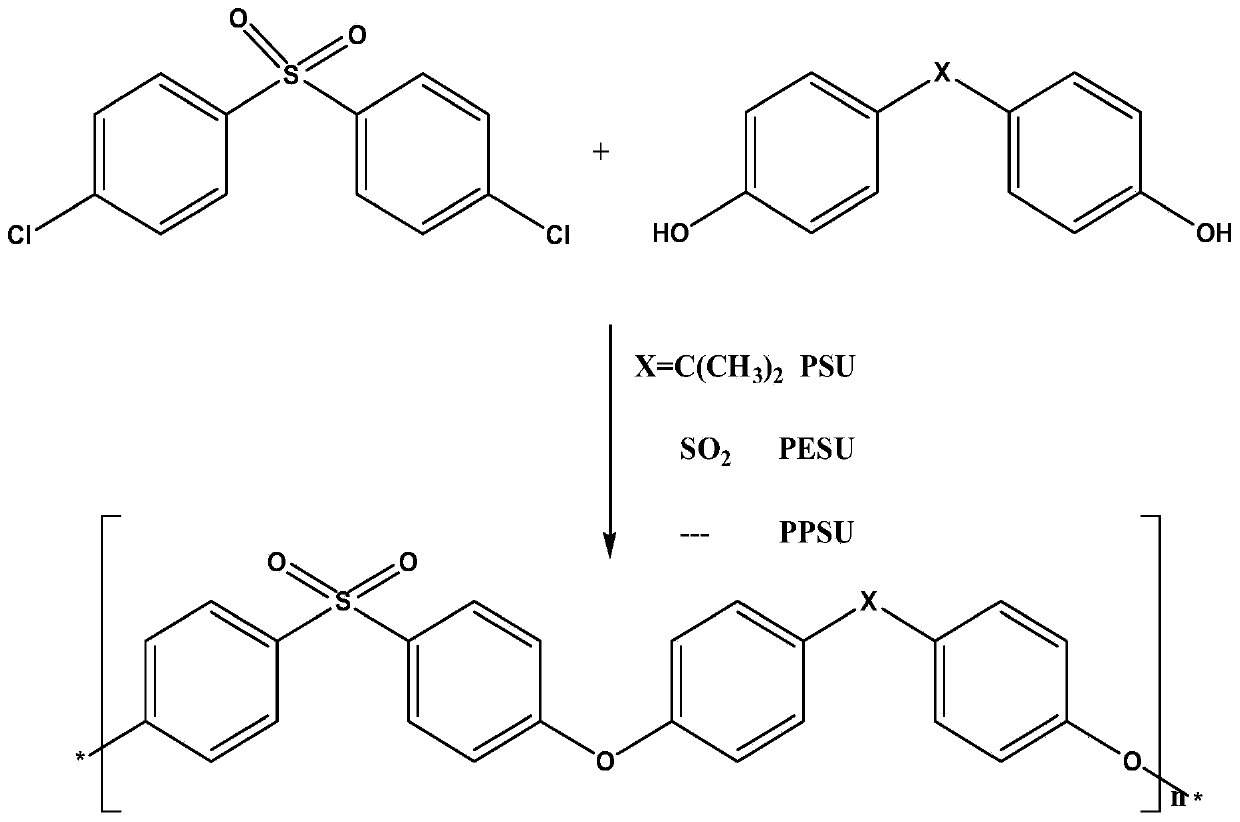

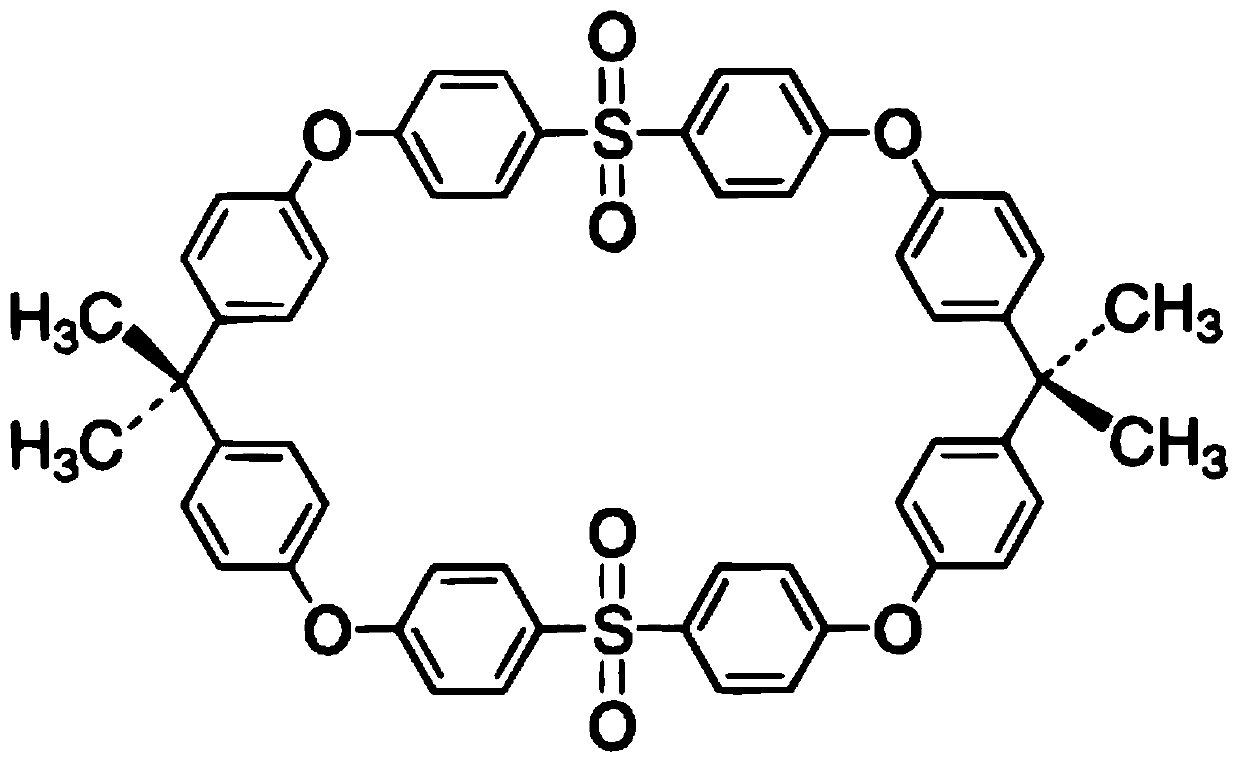

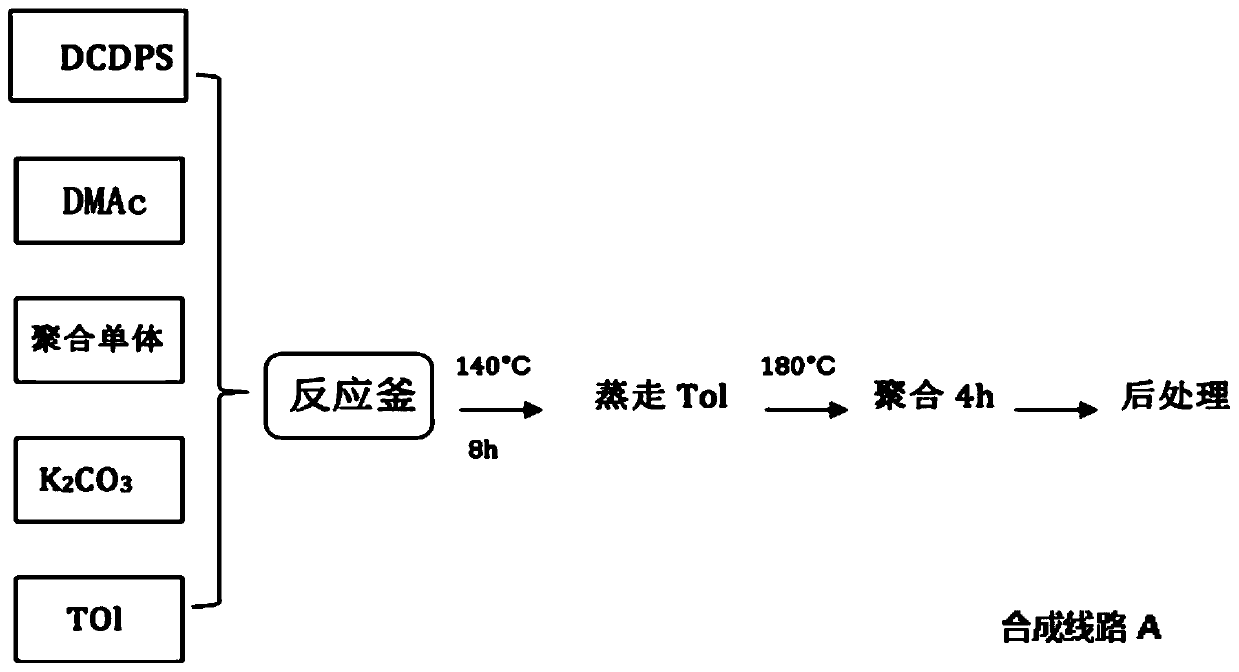

[0028] See figure 1 with figure 2 , figure 1 It is the polysulfone resin polymerization reaction diagram of the present invention; figure 2 It is the structural diagram of the polysulfone ring dimer described in the present invention. The invention provides a preparation method of a polysulfone resin polymer material. The preparation method uses 4,4'-dichlorodiphenylsulfone, potassium carbonate and polymerized monomers as raw materials, and uses dimethylacetamide as an organic solvent. Toluene or xylene is used as the water removal agent, and the preparation method comprises the following steps:

[0029] (1) mixing the above-mentioned 4,4'-dichlorodiphenyl sulfone, potassium carbonate, polymerizable monomers, dimethylacetamide and toluene for polymerization reaction to obtain a polymer solution; and

[0030] (2) After the polymer solution was cooled to room temperature, it was settled into deionized water, washed 5 times at 80°C, and dried to obtain a powdered polysulfon...

Embodiment 1

[0050] DMAC usage calculation coefficient X=0.1:

[0051] (1) 200LDMAC, 100L Tol, 10kg DCDPS, bisphenol A BPA 10kg, K 2 CO 3 11.5kg, all were added to a 500L reactor, under nitrogen protection, water was separated at 140°C for 8 hours, Tol was evaporated, the temperature was raised to 180°C, and polymerization was maintained at 180°C for 4 hours;

[0052] (2) Post-treatment: After the reaction is completed, cool to room temperature, settle into deionized water, wash 5 times at 80°C, and dry to obtain powdered bisphenol A polysulfone product (PSU);

[0053] (3) The intrinsic viscosity of the obtained polysulfone product was tested by Ubbelohde viscometer and the molecular weight distribution was tested by GPC by gel permeation chromatography, and the content of cyclic dimer was determined to be 0.013 wt%.

Embodiment 2

[0055] DMAC usage calculation coefficient X=0.18:

[0056] (1) 111.1L DMAC, 56.6L Tol, 10kg DCDPS, bisphenol A BPA 10kg, K 2 CO 3 11.5kg, all were added to a 300L reactor, under nitrogen protection, water was separated at 140°C for 8 hours, Tol was evaporated, the temperature was raised to 180°C, and polymerization was maintained at 180°C for 4 hours;

[0057] (2) Post-treatment: After the reaction is completed, cool to room temperature, settle into deionized water, wash 5 times at 80°C, and dry to obtain powdered bisphenol A polysulfone product (PSU);

[0058] (3) The intrinsic viscosity of the obtained polysulfone product was tested by Ubbelohde viscometer and the molecular weight distribution was tested by GPC by gel permeation chromatography, and the content of cyclic dimer was determined to be 0.011 wt%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com