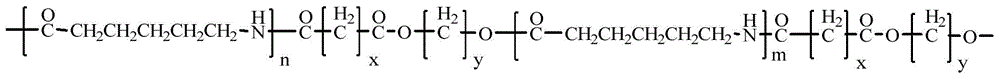

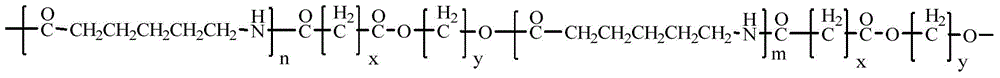

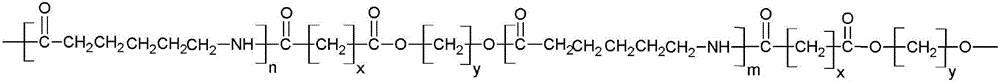

A kind of caprolactam hydrolysis polymer and its hydrolysis polymerization method

A technology of caprolactam and hydrolysis polymerization, applied in the field of polymer polymerization, can solve the problems of inability to control oligomers, low polymer molecular weight, slow reaction speed, etc., and achieve the effects of reducing energy consumption, improving utilization rate, and reducing possibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A method for hydrolytic polymerization of a caprolactam hydrolyzed polymer, the specific steps comprising:

[0039] The first step: at a temperature of 80°C, caprolactam, capping agent HOOC (CH 2 ) 2 COOH, deionized water and catalyst nylon 66 salt were mixed in proportion, mechanically stirred for 10min, and the rotating speed was 60r / min; wherein relative to caprolactam, the amount of deionized water added was 2wt%, and the capping agent HOOC(CH 2 ) 2 The addition of COOH is 5%, and the addition of catalyst nylon 66 salt is 0.1wt%;

[0040] The second step: pre-polymerize the mixture obtained in the first step under nitrogen atmosphere, the polymerization temperature is controlled at 150 ° C, and the polymerization pressure is controlled at 0.1 MPa; when the following conditions are met, the reaction is terminated: the molecular weight of the obtained prepolymer is 1000 , the content of terminal amino groups is ≤1mmol / kg, the content of extractables is ≤10wt%, and ...

Embodiment 2

[0045] The first step: at a temperature of 140°C, caprolactam, HOOC (CH 2 ) 10 COOH, deionized water and NH 2 (CH 2 ) 4 COOH was mixed in proportion, mechanically stirred for 60min, and the rotating speed was 240r / min; wherein relative to caprolactam, the amount of deionized water added was 5wt%, HOOC(CH 2 ) 10 The amount of COOH added is 30%, NH 2 (CH 2 ) 4 The amount of COOH added is 5wt%;

[0046] The second step: pre-polymerize the mixture obtained in the first step under a nitrogen atmosphere, the polymerization temperature is controlled at 200 ° C, and the polymerization pressure is controlled at 3 MPa; when the following conditions are met, the reaction is terminated: the molecular weight of the obtained prepolymer is 5000, Amino-terminal content ≤ 1mmol / kg, extractables content ≤ 10wt%, and cyclic dimer content ≤ 0.3wt%;

[0047] The third step: adding tetrabutyl titanate as a transesterification catalyst, the addition amount is 500ppm of the caprolactam mass ...

Embodiment 3

[0052] A method for hydrolytic polymerization of a caprolactam hydrolyzed polymer, the specific steps comprising:

[0053] The first step: under the condition of temperature of 100 ℃, caprolactam, capping agent HOOC (CH 2 ) 5 COOH, deionized water and catalyst NH 2 (CH 2 ) 10 COOH was mixed in proportion, mechanically stirred for 30min, and the rotating speed was 100r / min; wherein relative to caprolactam, the amount of deionized water added was 3wt%, and the capping agent HOOC(CH 2 ) 5 The amount of COOH added is 10%, the catalyst NH 2 (CH 2 ) 10 The amount of COOH added is 0.1-5wt%;

[0054] The second step: pre-polymerize the mixture obtained in the first step under nitrogen atmosphere, the polymerization temperature is controlled at 180 ° C, and the polymerization pressure is controlled at 0.5 MPa; when the following conditions are met, the reaction is terminated: the molecular weight of the obtained prepolymer is 3000 , the content of terminal amino groups is ≤1mm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com