Environment-friendly silver plating process for plating silver on surface of aluminum alloy once

An aluminum alloy surface, aluminum alloy technology, applied in metal material coating process, liquid chemical plating, coating and other directions, can solve problems such as environmental pollution, avoid secondary pollution, dense silver layer, improve bonding force. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

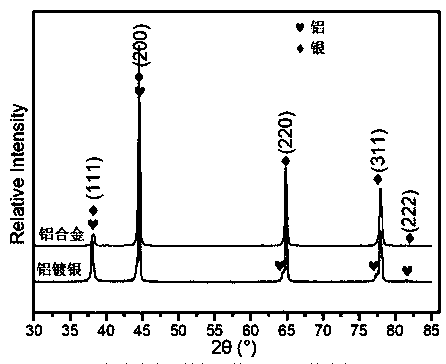

Image

Examples

Embodiment 1

[0025] The environmentally friendly silver plating process of one-time silver plating on the aluminum alloy surface includes: electroless plating process: smooth surface polishing → roughening treatment → hydroxylation treatment → KH580 surface modification → environmentally friendly silver plating.

[0026] The specific process is as follows:

[0027] Step S1 coarsening treatment: Add 2 mL of HCl solution dropwise into 18 mL of deionized water, and add 3.4 g of NH 4 F, stirring and dissolving to obtain a roughening solution; immerse the aluminum alloy sample in the roughening solution, and ultrasonicate for 10 minutes under low-frequency ultrasonic conditions to roughen the surface;

[0028] Step S2 hydroxylation treatment: configure a NaOH solution with a mass fraction of 10%, immerse the sample treated in step S1 in the NaOH solution, and sonicate for 10 minutes under low-frequency ultrasonic conditions;

[0029] Step S3 KH580 surface modification treatment: Dissolve KH580...

Embodiment 2

[0034] The environmentally friendly silver plating process of one-time silver plating on the aluminum alloy surface includes: electroless plating process: smooth surface polishing → roughening treatment → hydroxylation treatment → KH580 surface modification → environmentally friendly silver plating.

[0035] The specific process is as follows:

[0036] Step S1 coarsening treatment: Add 2 mL of HCl solution dropwise into 18 mL of deionized water, and add 3.4 g of NH 4 F, stirring and dissolving to obtain a roughening solution; immerse the aluminum alloy sample in the roughening solution, and ultrasonicate for 10 minutes under low-frequency ultrasonic conditions to roughen the surface;

[0037] Step S2 hydroxylation treatment: configure a NaOH solution with a mass fraction of 10%, immerse the sample treated in step S1 in the NaOH solution, and sonicate for 10 minutes under low-frequency ultrasonic conditions;

[0038] Step S3 KH580 surface modification treatment: Dissolve KH580...

Embodiment 3

[0043] The environmentally friendly silver plating process of one-time silver plating on the aluminum alloy surface includes: electroless plating process: smooth surface polishing → roughening treatment → hydroxylation treatment → KH580 surface modification → environmentally friendly silver plating.

[0044] The specific process is as follows:

[0045] Step S1 coarsening treatment: Add 2 mL of HCl solution dropwise into 18 mL of deionized water, and add 3.4 g of NH 4 F, stirring and dissolving to obtain a roughening solution; immerse the aluminum alloy sample in the roughening solution, and ultrasonicate for 10 minutes under low-frequency ultrasonic conditions to roughen the surface;

[0046] Step S2 hydroxylation treatment: configure a NaOH solution with a mass fraction of 10%, immerse the sample treated in step S1 in the NaOH solution, and sonicate for 10 minutes under low-frequency ultrasonic conditions;

[0047] Step S3 KH580 surface modification treatment: Dissolve KH580...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com