Actual drilling simulation and drilling parameter testing device and method for nearly horizontal directional drilling

A technology of drilling parameters and horizontal orientation, applied in directional drilling, drilling equipment and methods, earthwork drilling, etc., can solve problems such as difficulties in test sites, inability to fully grasp geological conditions, inability to collect relevant parameters, etc., to improve monitoring Level and accuracy, direct observation is more convenient, and the effect of improving the test environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

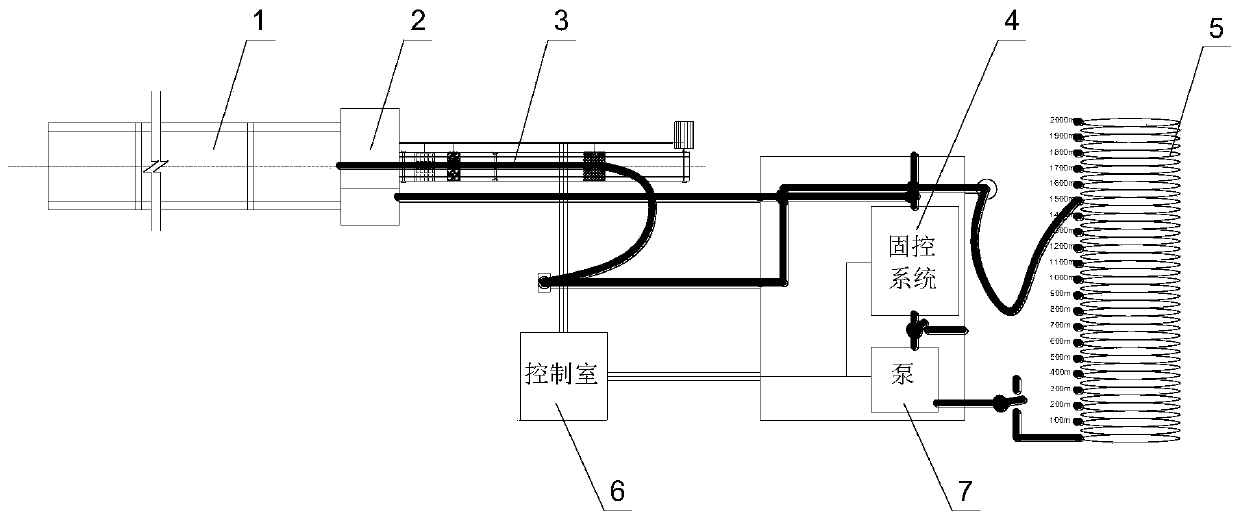

[0046] Such as figure 1 As shown, the near-horizontal directional drilling actual drilling simulation and drilling parameter test bench includes simulated geological body 1, drilling drive system 3, mud pump 7, solid control system 4, manifold system 5 and monitoring control system 66 part.

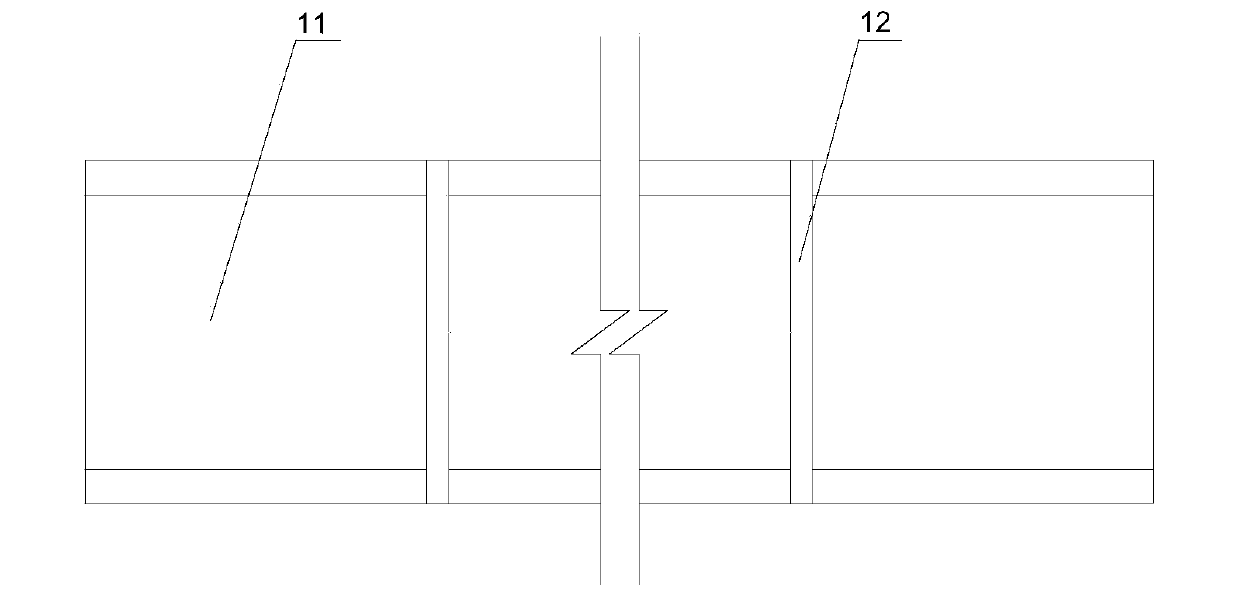

[0047] Such as figure 2 As shown, the simulated geological body is a concrete cylinder 11 fixed on the ground, which is assembled by multi-section prefabricated concrete cylinders. The length of the assembly is determined according to the test requirements. The axes are coincident, and the assembly gap 12 is poured with concrete of the same label as the concrete cylinder, so that it becomes a whole.

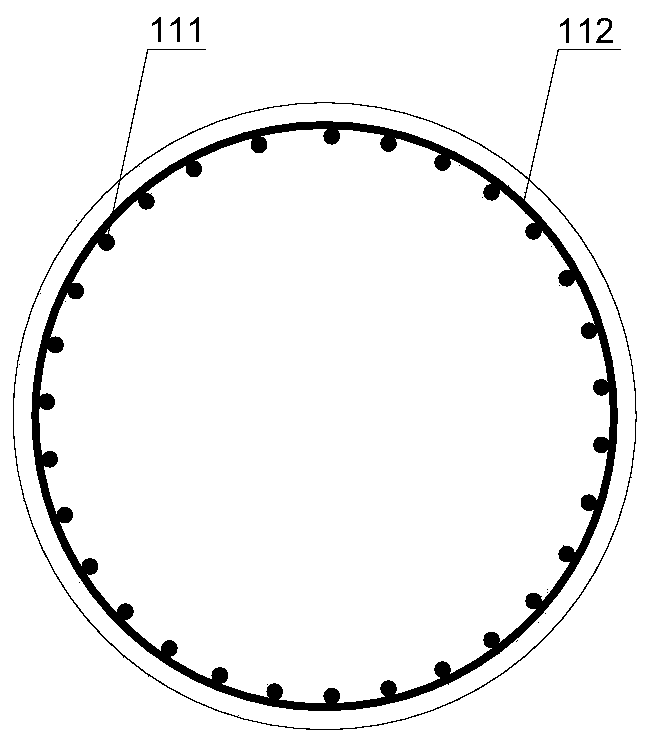

[0048] Such as image 3As shown, in order to ensure the strength and integrity of the concrete block so that it does not crack during drilling, the concrete cylinder is respectively equipped with main reinforcement 111 and stirrup 112, and the drilling track is arranged in the concrete w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com