Installation structure of compressor impeller

A compressor impeller and installation structure technology, which is applied to components, mechanical equipment, machines/engines, etc. of pumping devices used for elastic fluids, and can solve the problems of repeated assembly and disassembly limiting the application range of centrifugal refrigeration compressors, etc. , to achieve the effect of great practical value, easy popularization and application, and simple connection structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

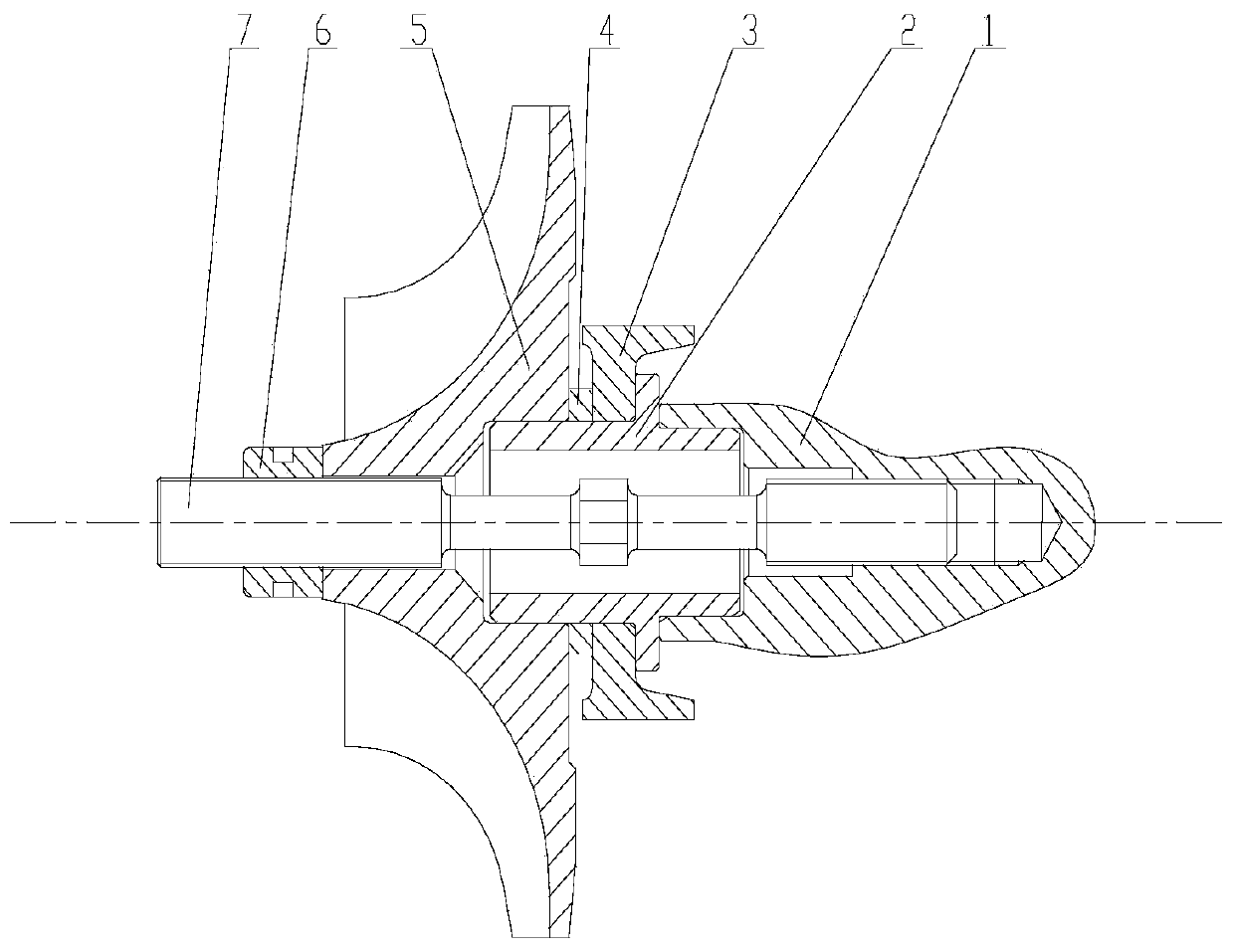

[0028] Example 1, such as figure 1 As shown, a compressor impeller installation structure is provided, including a motor rotor shaft 1, a transition sleeve 2, a center tie rod 7, an impeller 5, a compression nut 6, an adjustment pad 4 and a balance plate 3;

[0029] The shaft end of the motor rotor shaft has an axial step hole, the small hole of the step hole is an internal thread hole, and the large hole of the step hole is a positioning hole;

[0030] Both ends of the center tie rod have external threads, the threads at both ends have the same rotation direction, the external threads at one end are fastened with the internal thread holes of the motor rotor shaft, and the rotation direction of the external threads at one end is opposite to the rotation direction of the motor rotor shaft;

[0031] The transition bushing is set outside the center tie rod, and the outer diameter of one end of the transition bushing matches the inner diameter of the large hole, and is positioned ...

Embodiment 2

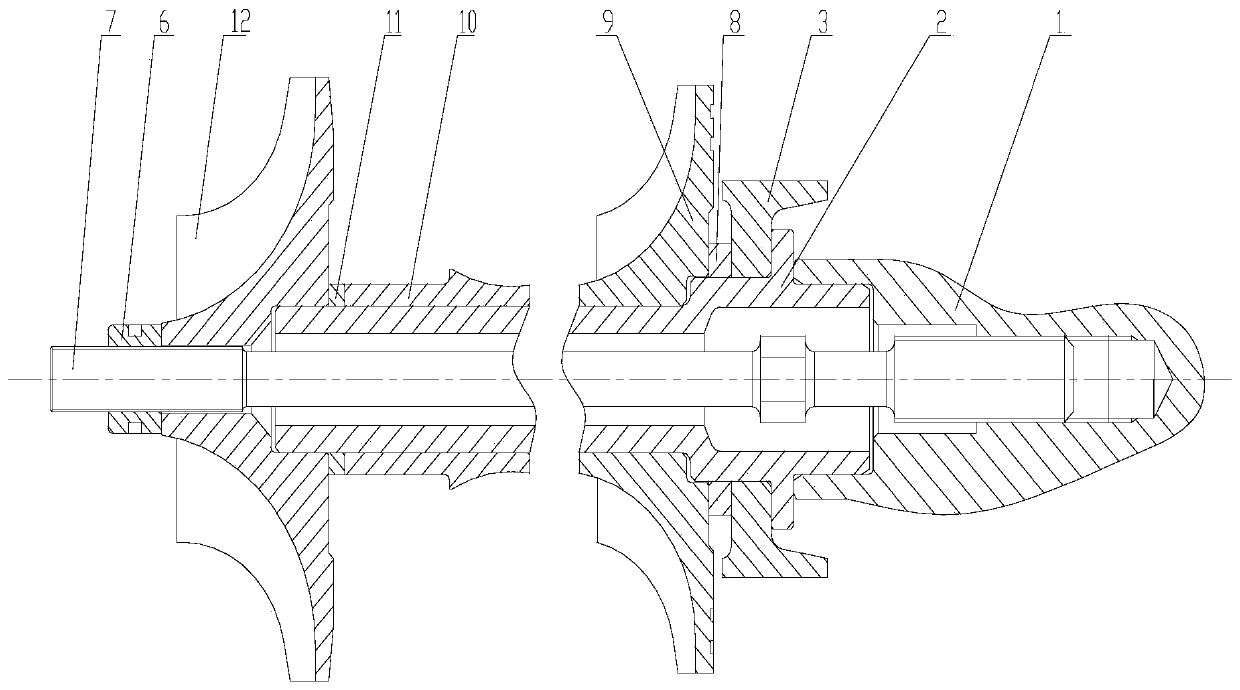

[0033] Example 2, such as figure 2 As shown, there is provided an installation structure for multi-stage impellers of a compressor, including a motor rotor shaft, a transition sleeve, a central tie rod, at least two impellers, at least one spacer sleeve, a compression nut, at least two adjustment pads and a balance plate; There is an adjusting pad and a spacer sleeve between the impellers of each stage;

[0034] The shaft end of the motor rotor shaft has an axial step hole, the small hole of the step hole is an internal thread hole, and the large hole of the step hole is a positioning hole;

[0035] Both ends of the center tie rod have external threads, the threads at both ends have the same rotation direction, the external threads at one end are fastened with the internal thread holes of the motor rotor shaft, and the rotation direction of the external threads at one end is opposite to the rotation direction of the motor rotor shaft;

[0036] The transition bushing is set o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com