Substrate storage container management system, load port, and substrate storage container management method

A storage container and loading port technology, which is applied to instruments, storage devices, transportation and packaging, etc., can solve the problems of gas FOUP inflow, sensor detection and processing, and difficulty in introducing into the manufacturing site, so as to reduce the frequency of errors and the change of stop time. Short, productivity-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] Hereinafter, a first embodiment of the present invention will be described with reference to the drawings.

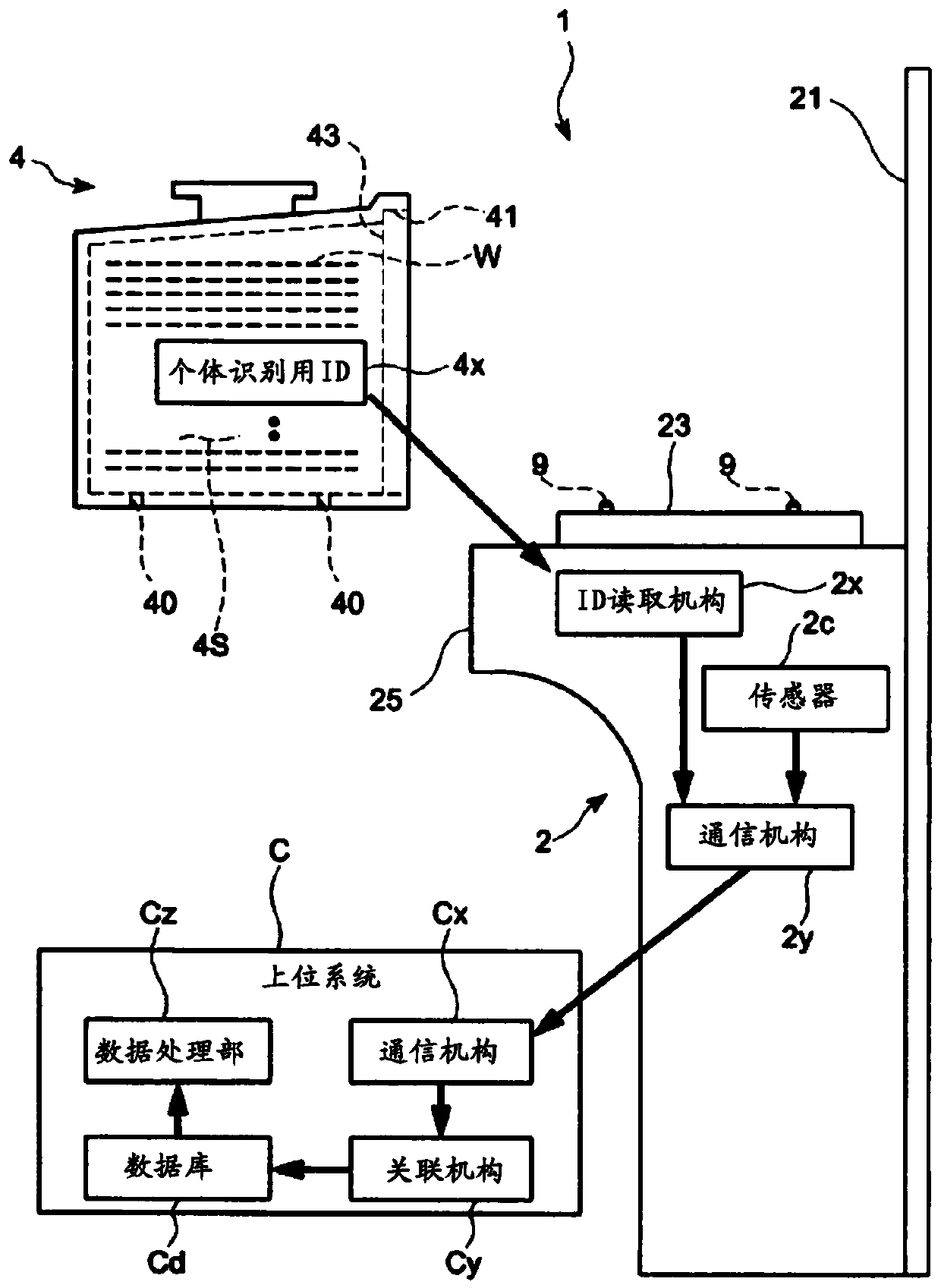

[0060] For example, if figure 1 As shown, the substrate storage container management system 1 of this embodiment is constituted by using the FOUP 4 as a substrate storage container used in the semiconductor manufacturing process, the load port 2, and the host system C. Specifically, it is a system as follows: from the load port The communication mechanism 2y of 2 sends to the host system C the ID 4x for individual identification attached to the FOUP 4 and the sensor value related to the FOUP 4 detected by the sensor 2c installed in the loading port 2, and the ID 4x for individual identification is sent to the host system C. And the sensor value is associated and databased, and the state of FOUP4 can be output based on the data of the database Cd.

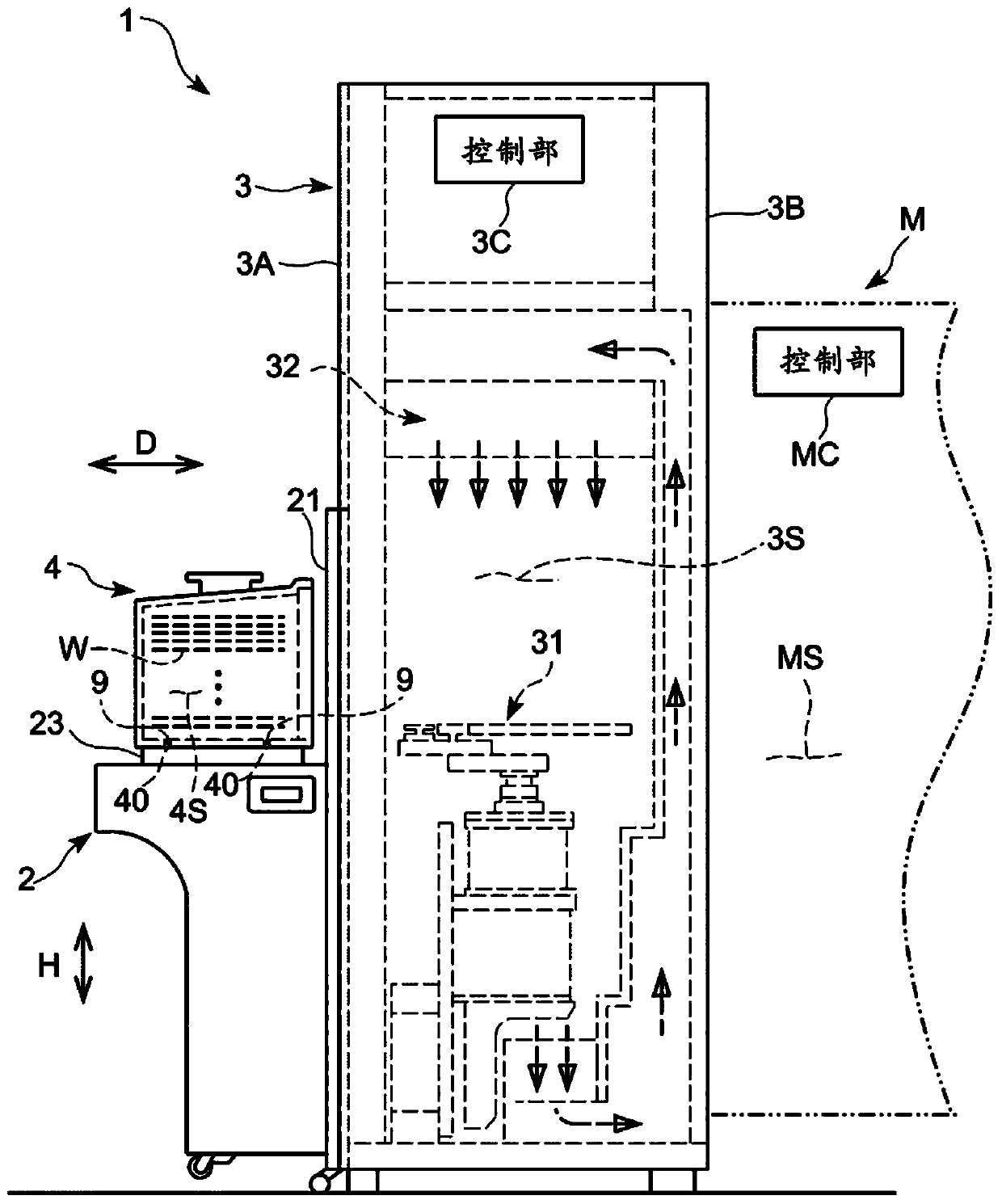

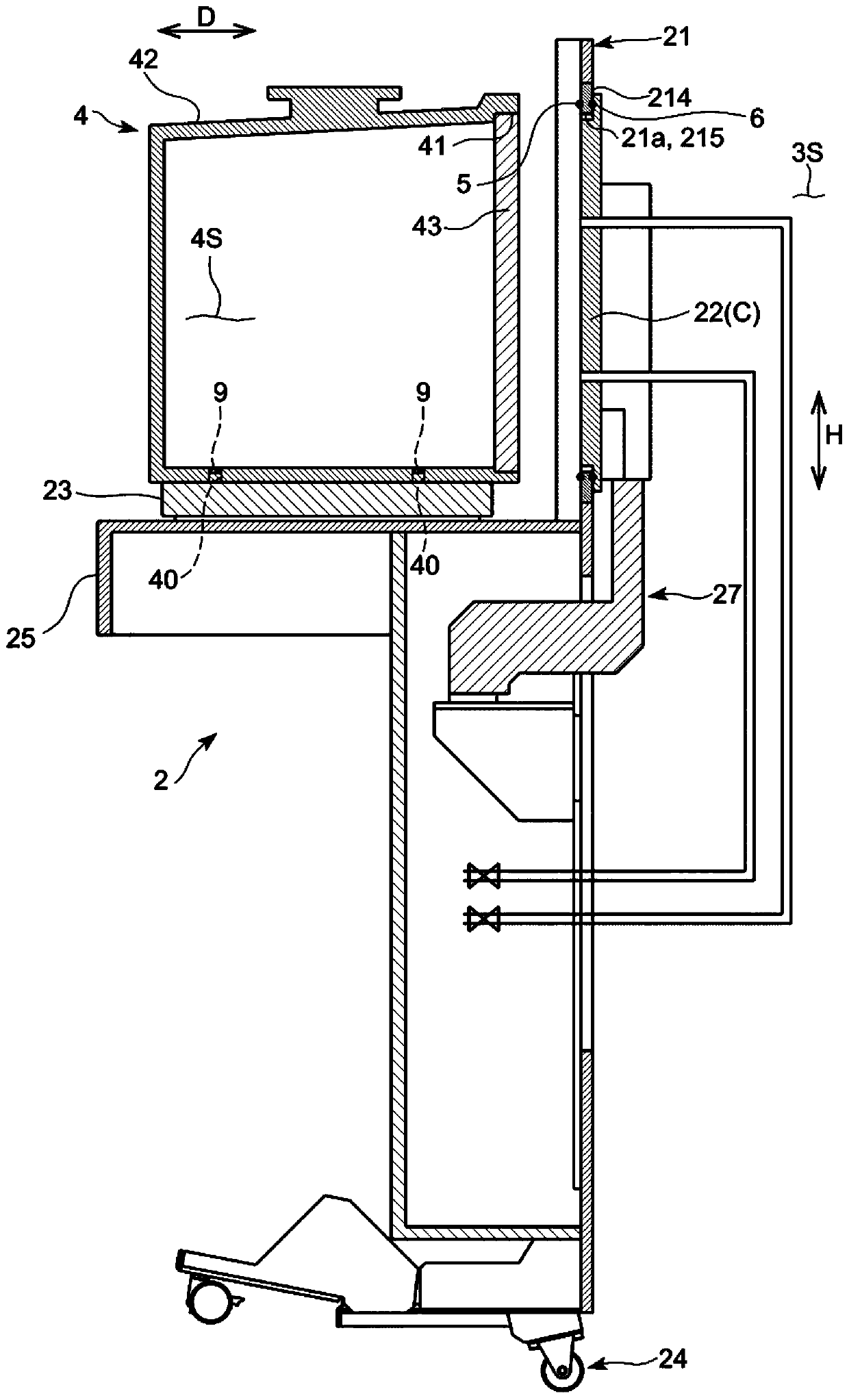

[0061] Such as figure 2 As shown, in the semiconductor manufacturing process, the FOUP 4 is used together with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com