A kind of reconstituted tobacco leaf for heating cigarette and its improved dry method preparation method

A technology of reconstituted tobacco leaves and dry process, which is applied in the field of reconstituted tobacco leaves for heating cigarettes and its improved dry process, which can solve the problems of low tightness, bulk, air permeability, high porosity, concentration, fullness, fullness, Problems such as lumpiness and lack of thickness, etc., to achieve the effects of increased tightness, enhanced thickness, and enhanced machine adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

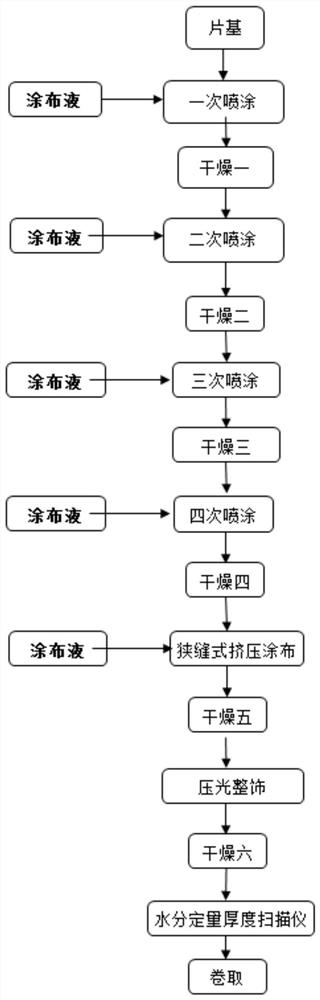

[0040] The defibrated coniferous wood pulp and flax pulp are mixed according to the mass ratio of 8:2, and the dry-laid film base is prepared after air-flow forming at the forming head, and the basis weight is 20g / m 2 , the bulk thickness is 6cm 3 / g. According to product design requirements and formula requirements, the coating liquid for coating is prepared. The formula of the coating liquid is: by weight, 10 parts of tobacco particles (200 mesh), 4 parts of smoking agent, 4 parts of adhesive, tobacco extract 3 parts of substance, 2 parts of dispersant, 3 parts of food additive, 2 parts of tobacco essence, 80 parts of water, the solid content of the coating liquid is 10%, and the viscosity is 380mPa·s. figure 1 In the process flow shown, the prepared coating solution is sprayed four times (each spraying amount is 25g / m 2 ), one-time slot extrusion coating (the coating amount is 30g / m 2 ) is transferred to the sheet base and the surface of the coated substrate to obtain a ...

Embodiment 2

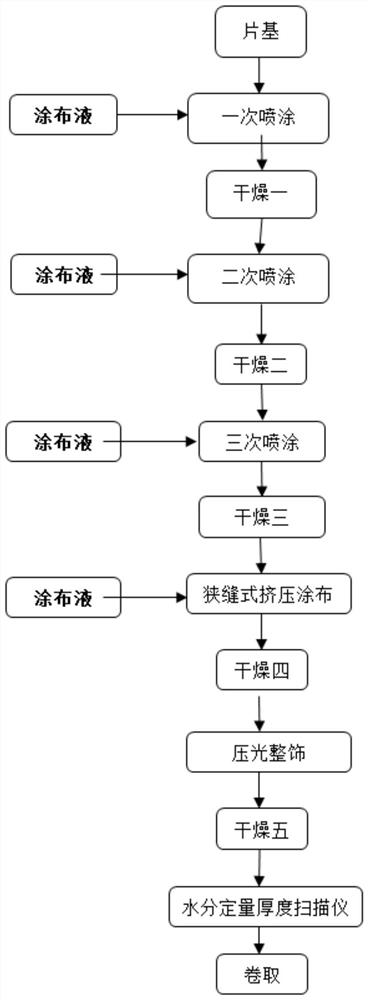

[0042] The defibrated coniferous wood pulp, tobacco stem pulp, and tobacco stem pulp were mixed according to the mass ratio of 6:1:3, and air-flow formed by the forming head to prepare a dry-laid sheet base, with a weight of 40g / m 2 , the bulk thickness is 4.8cm 3 / g. Prepare coating liquid for coating according to product design requirements and formula requirements, the formula of coating liquid is: by weight, 15 parts of tobacco particles (200 mesh), 6 parts of smoking agent, 5 parts of adhesive, tobacco extract 4 parts of substance, 2 parts of dispersant, 3 parts of food additive, 2 parts of essence for tobacco, 85 parts of water, the solid content of the coating liquid is 12%, and the viscosity is 860mPa·s. The coating solution has a solid content of 15% and a viscosity of 850mP·s. figure 2 As shown in the process flow, the prepared coating liquid is sprayed three times (each spraying amount is 25g / m 2 ), one-time slot extrusion coating (the coating amount is 35g / m 2...

Embodiment 3

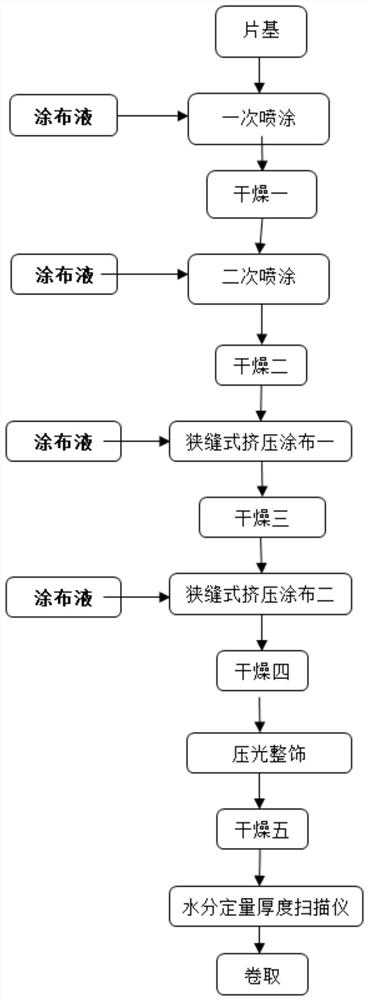

[0044] The defibrated coniferous wood pulp and bamboo pulp are mixed according to the mass ratio of 7:3, and the dry-laid film base is prepared after air-flow forming at the forming head, and the basis weight is 60g / m 2 , the bulk thickness is 7cm 3 / g. Prepare coating liquid for coating according to product design requirements and formula requirements, the formula of coating liquid is: by weight, 20 parts of tobacco particles (200 mesh), 8 parts of smoking agent, 6 parts of adhesive, tobacco extract 5 parts of substance, 3 parts of dispersant, 4 parts of food additive, 3 parts of tobacco essence, 90 parts of water; the solid content of coating liquid is 20%, the viscosity is 1370mP·s, according to the image 3 As shown in the process flow, the prepared coating liquid is sprayed twice and the amount of each spray is 30g / m 2 ), two slit extrusion coatings (35g / m 2 ) is transferred to the sheet base and the surface of the coated substrate to obtain a semi-finished reconstitut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com