Preparation method of broken-wall decoction piece of ganoderma

A technology of breaking the wall of Ganoderma lucidum and decocting pieces, which is applied in the direction of medical preparations containing active ingredients, medical formulas, and block transportation, etc. It can solve the problems of microbial limit, rapid dissolution of unfavorable medicinal active ingredients, unsuitable medicinal materials, etc. , to achieve the effect of ensuring the safety and efficacy of medication, moderate tightness and easy drying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

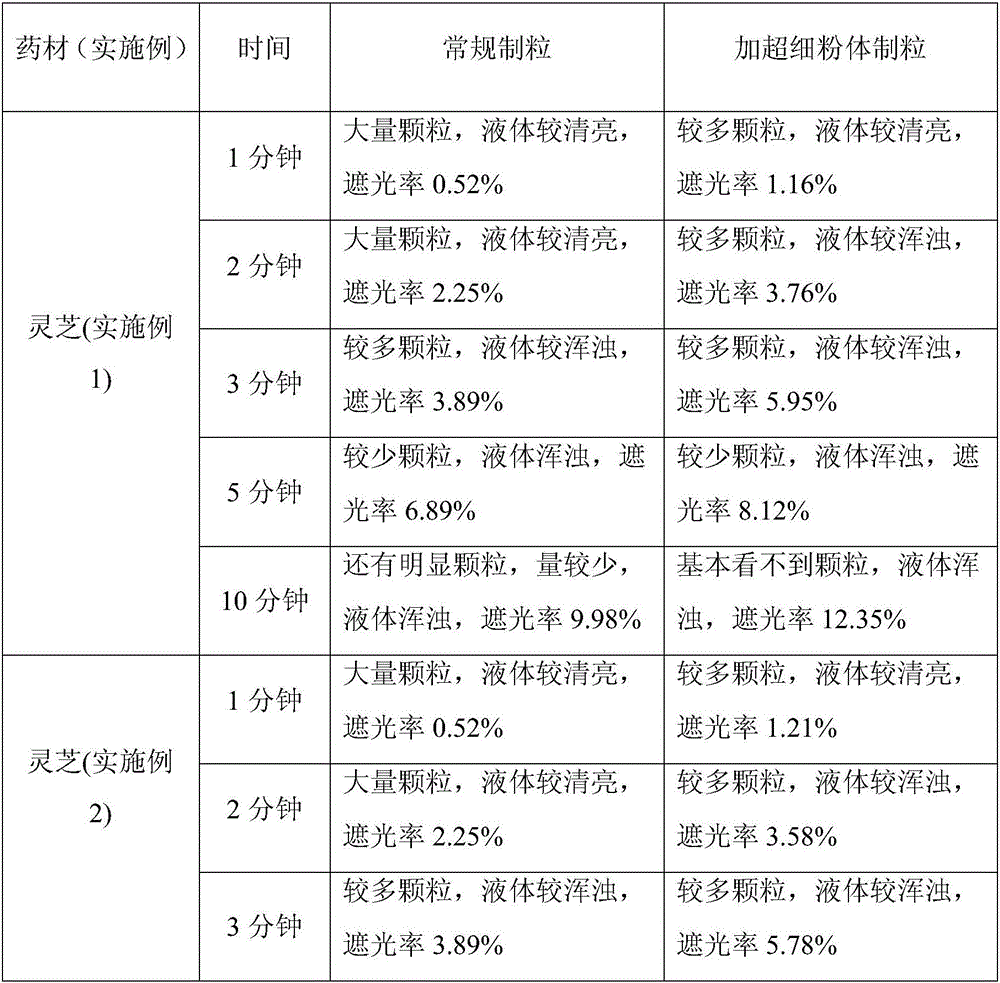

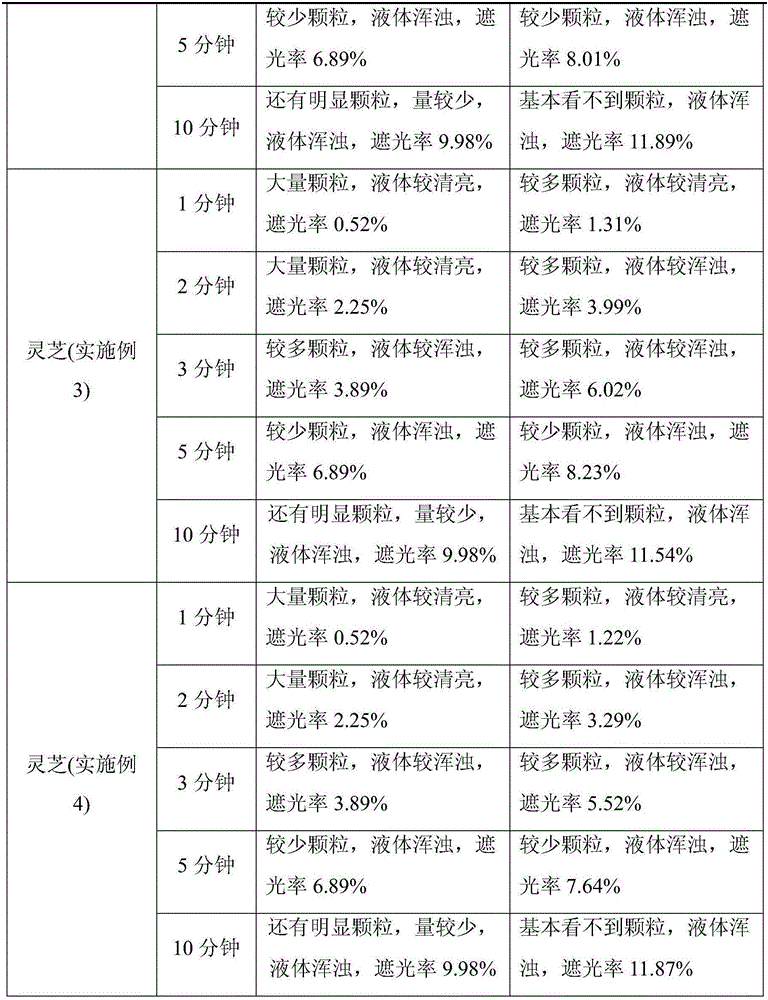

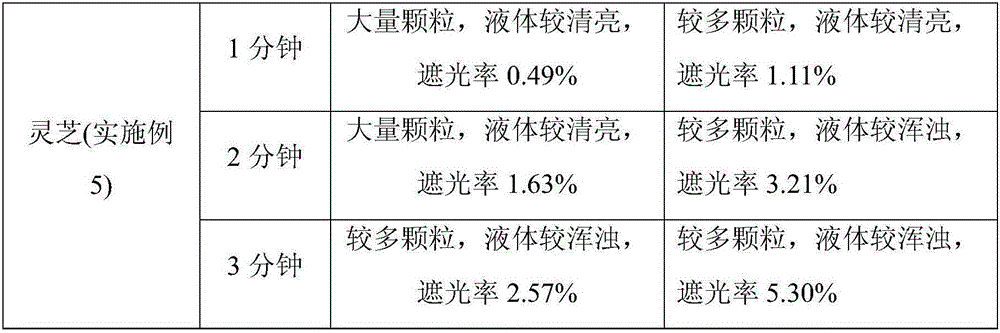

Examples

Embodiment 1

[0040] Ganoderma lucidum broken wall drink

[0041] 1) Medicinal material processing: pick and clean / process the Ganoderma lucidum medicinal material, dry the medicinal material until the water content of the medicinal material is below 10%, and crush the medicinal material into small particles of about 10 mesh with a 10-mesh sieve; further coarsely pulverize the Ganoderma lucidum Reach about 100 mesh;

[0042] 2) Intermittent sterilization: kill bacteria propagules: place Ganoderma lucidum coarse powder in an oven with a thickness of about 10mm, set the temperature at 65°C (actual temperature is 60-70°C), keep dry and sterilize for 8 hours; dormant body growth: treatment The final Ganoderma lucidum powder is taken out from the oven, packed into bags, and when the temperature is 25°C, fill the bag with water vapor and seal it for 12 hours; to kill bacteria propagules: put the Ganoderma lucidum powder into the oven with a thickness of 30mm , set the temperature at 75°C (the ac...

Embodiment 2

[0048] Ganoderma lucidum broken wall drink

[0049] 1) Medicinal material processing: Ganoderma lucidum is sorted, cleaned / processed, and dried until the water content of the medicinal material is below 10%, and then crushed into small particles of about 10 mesh by a mechanical crusher with a 10-mesh screen; left and right;

[0050] 2) Intermittent sterilization: kill bacteria propagules: put Ganoderma lucidum coarse powder in an oven with a thickness of about 5mm, set the temperature at 70°C (actual temperature is 65-75°C), keep dry and sterilize for 4 hours; dormant body growth: treatment The final Ganoderma lucidum powder is taken out from the oven, packed into bags, and when the temperature is 20°C, fill the bag with water vapor and seal it for 15 hours; to kill bacteria propagules again: put the Ganoderma lucidum powder into the oven with a thickness of 20mm, set the temperature at 65°C (the actual temperature is 60-70°C), keep it dry and sterilized for 6 hours; repeat t...

Embodiment 3

[0056] Ganoderma lucidum broken wall drink

[0057] 1) Medicinal material processing: Ganoderma lucidum is sorted, cleaned / processed, and dried until the water content of the medicinal material is below 10%, and then crushed into small particles of about 10 mesh by a mechanical crusher with a 10-mesh screen; left and right;

[0058] 2) Intermittent sterilization: kill bacteria propagules: put Ganoderma lucidum coarse powder in an oven with a thickness of about 30mm, set the temperature at 75°C (actual temperature is 70-80°C), keep dry and sterilize for 4 hours; dormant body growth: treatment The final Ganoderma lucidum powder is taken out from the oven, packed into bags, and when the temperature is 25°C, fill the bag with water vapor and seal it for 24 hours; to kill bacteria propagules again: place the Ganoderma lucidum powder in the oven with a thickness of 10mm , set the temperature at 75°C (the actual temperature is 70-80°C), keep it dry and sterilized for 0.5h; repeat th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com