A Thickness Control Method for Hot Continuous Rolling Based on Improved Internal Model Controller

An internal mold controller and thickness control technology, applied in rolling mill control devices, manufacturing tools, metal rolling, etc., can solve the problems of system instability, poor system robustness, and reduced monitoring AGC performance, and achieve anti-interference performance and The effect of improving response performance, improving control quality and robustness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below through specific embodiments.

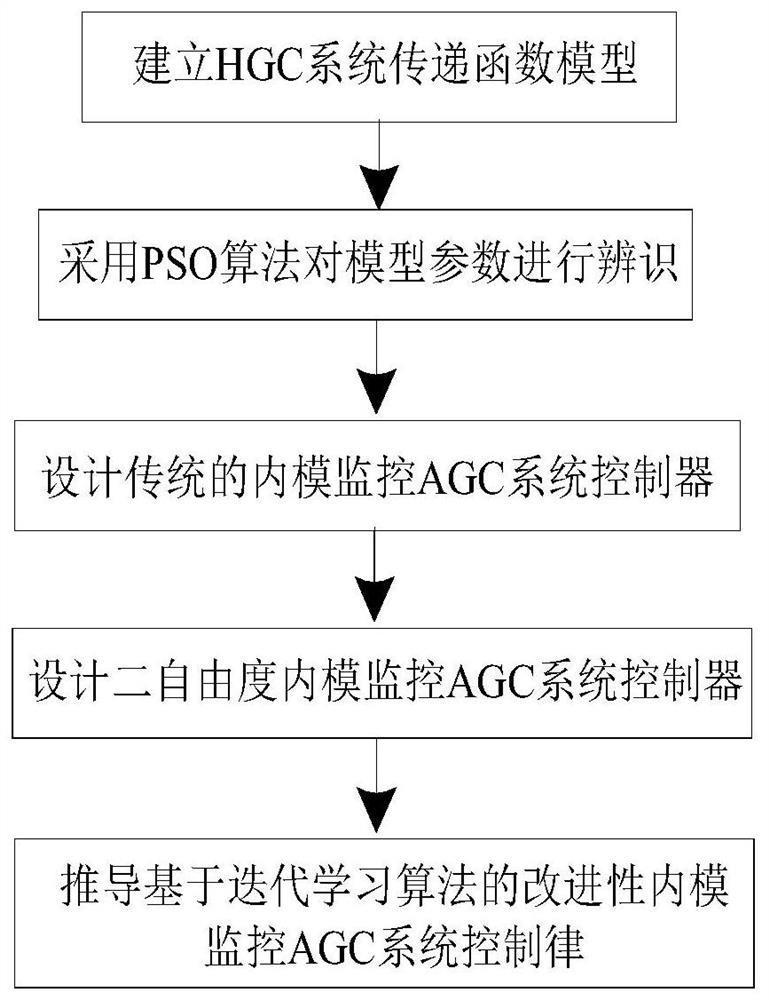

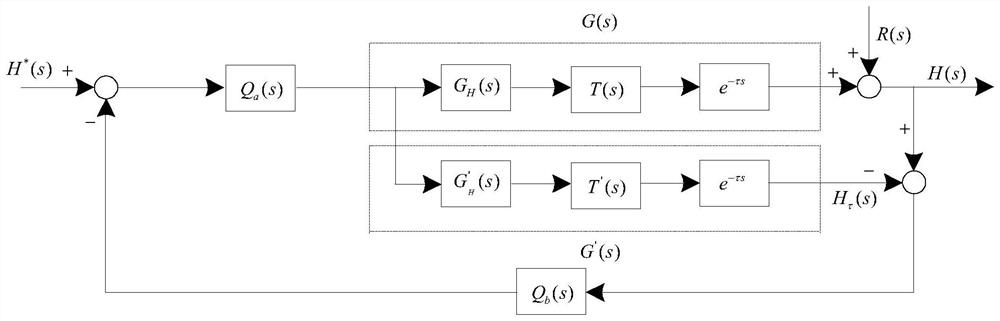

[0031] refer to figure 1 , a hot rolling thickness control method based on the improved internal model controller, the obtained improved internal model monitoring AGC thickness control amount based on the iterative learning algorithm can improve the robustness of the monitoring AGC system and provide high thickness accuracy The strip hot rolling processing provides a guarantee. The present invention specifically comprises the steps:

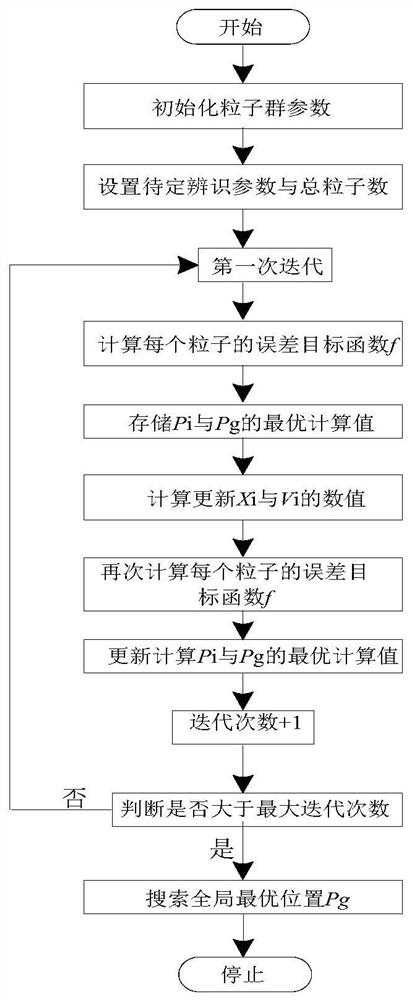

[0032] 1) Establish the transfer function model of each substructure of the HGC system in the monitoring AGC system, and use the PSO algorithm to identify the parameters of the transfer function model.

[0033] 1.1) Using the Laplace transform method, the transfer functions of the servo valve amplifier, servo valve, displacement sensor, hydraulic cylinder and load are respectively established, and the sub-links are connected together to establish the ov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com