Plastic product cutting device

A cutting device and technology for plastic products, applied in the field of plastic product processing, can solve the problems of inability to clean, poor adjustment ability, etc., and achieve the effects of reducing work intensity, convenient cutting, and good practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

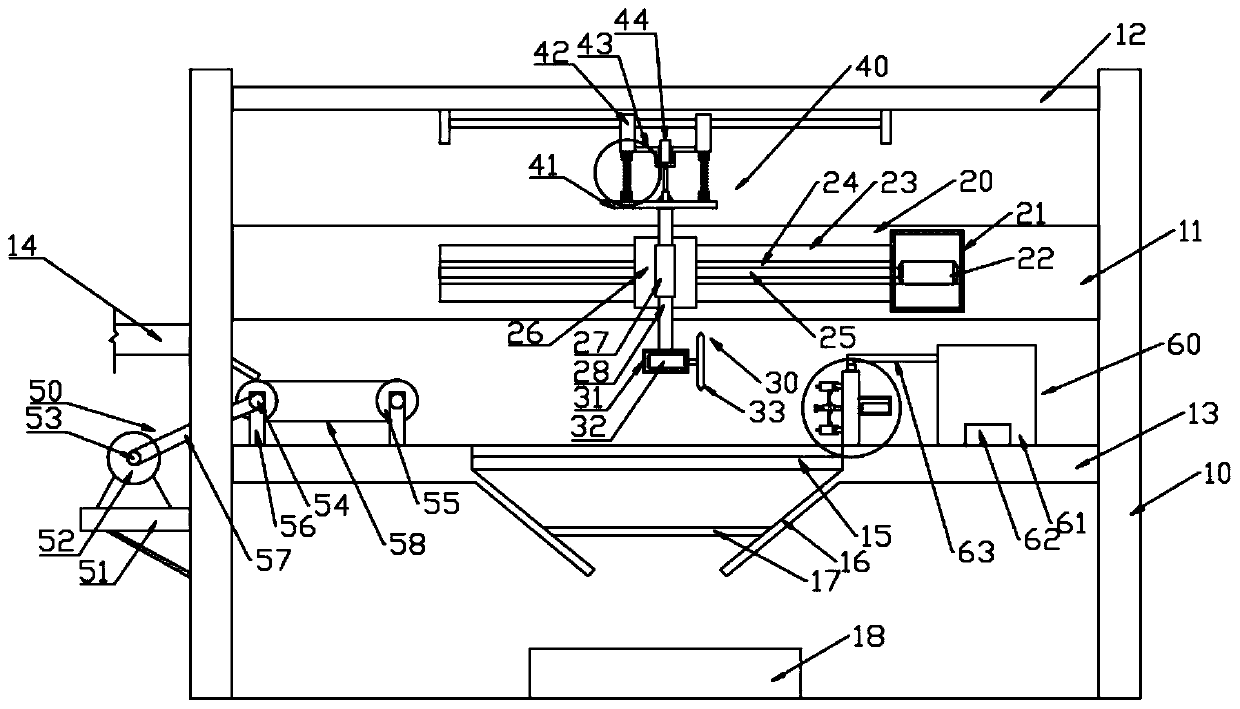

[0027] see Figure 1~4 , in an embodiment of the present invention, a cutting device for plastic products includes a vertical plate 10, a first fixed plate 11, a second fixed plate 12 and a cutting table 13 are fixed between the vertical plates 10, the first fixed plate 11 is used for The horizontal movement of the cutting assembly 30 is facilitated, the second fixing plate 12 facilitates the vertical movement of the cutting assembly 30 , and the cutting table 13 facilitates placement of plastic products for cutting by the cutting assembly 30 .

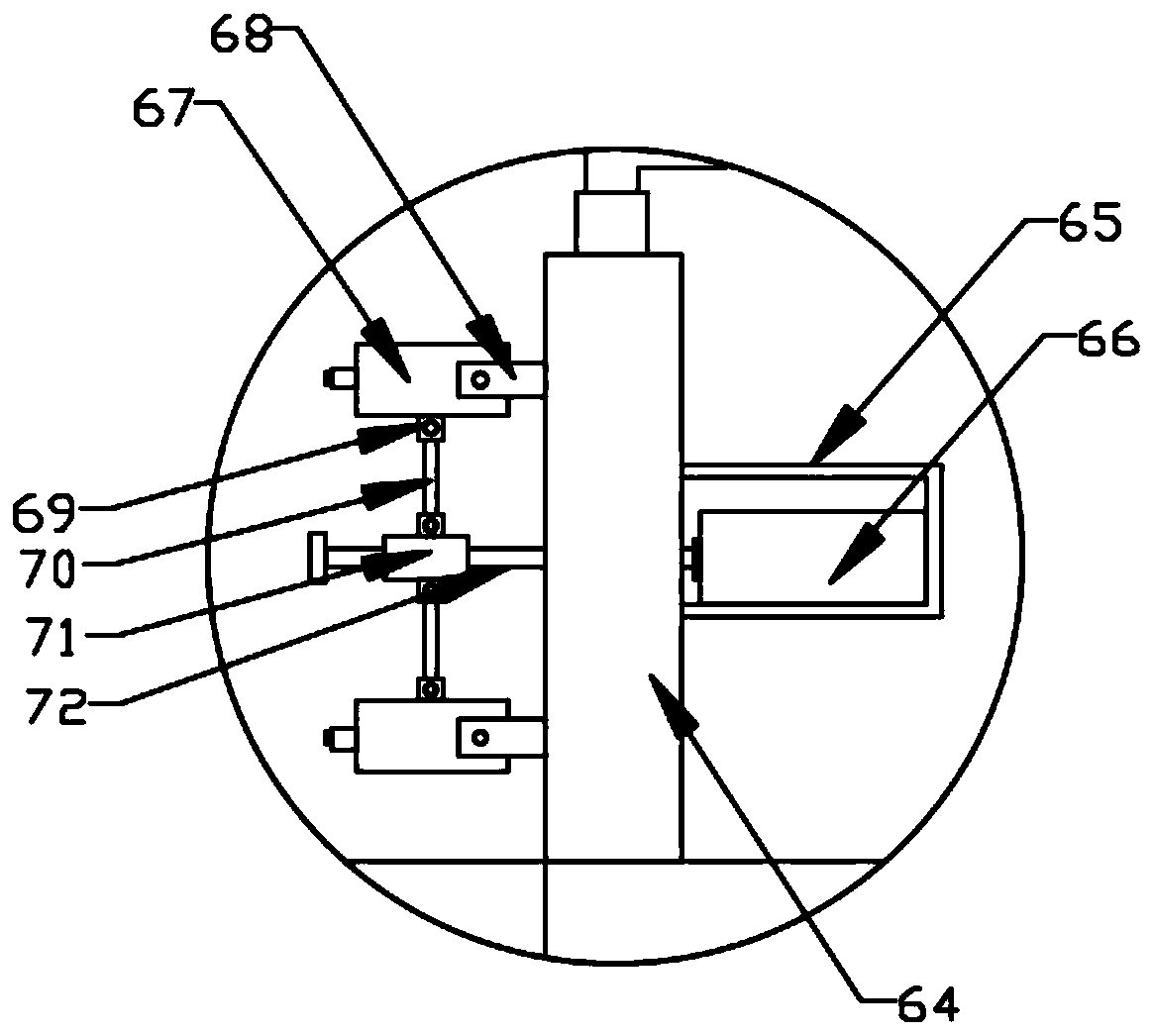

[0028] Further, the cutting table 13 is provided with a cutting chamber 15, and the plastic product is placed on the cutting chamber 15 to facilitate the cutting by the cutting assembly 30; a conveying assembly 50 is arranged on one side of the cutting chamber 15, and the conveying assembly 50 is arranged on the feeding Below the port 14, the plastic products transported by the feed port 14 can be moved to the cutting cavity 15 throug...

Embodiment 2

[0033] The difference between the embodiment of the present invention and embodiment 1 is that a baffle plate 16 is obliquely fixed below the cutting cavity 15, and a filter screen 17 is arranged on the baffle plate 16, and the cleaned water is filtered through the filter screen 17, and the In order to reduce impurities and then meet the discharge standard of sewage, a water collection box 18 is placed under the baffle plate 16 through which the cleaned sewage is collected.

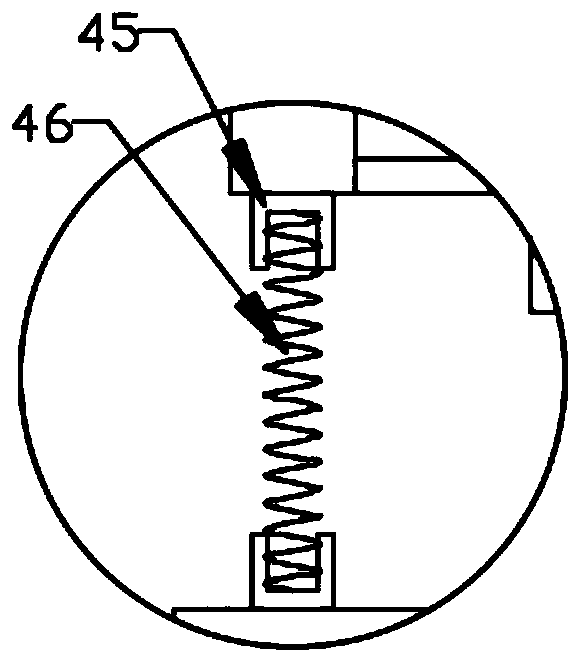

[0034] The working principle of the present invention is: firstly open the second motor 52, transmit the plastic product to the cutting chamber 15 through the conveying assembly 50, then open the first motor 22, adjust the position of the slide block 26 by the rotation of the first threaded rod 25, Adjust the cutting assembly 30 to a suitable position, then open the cylinder 44, adjust the vertical height of the cutting assembly 30, finally turn on the second motor 32, and cut the plastic product by the cu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com