Preparation method, product and application of a purple cabbage anthocyanin-nano chitin gelatin composite film

A nano-chitin and purple cabbage technology, applied in the field of food intelligent packaging, can solve the problems of anthocyanin stability and oxidation resistance decline, susceptibility to high temperature, strong light and strong alkali, anthocyanin instability, etc., to achieve Excellent biocompatibility, improved mechanical properties, and simplified preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

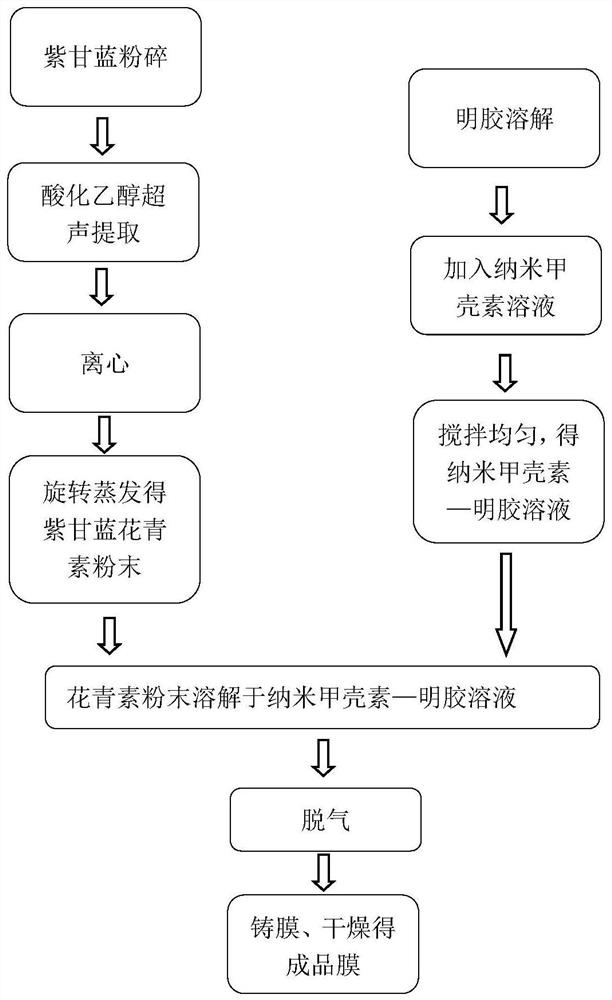

Method used

Image

Examples

Embodiment 1

[0029] (1) Preparation of purple cabbage anthocyanins: 10 g of purple cabbage was crushed and added to 100 mL of acidified ethanol, ultrasonically extracted, and centrifuged to obtain a purple cabbage anthocyanin solution. The obtained solution was rotary evaporated, placed at -80°C for 12-48 hours, and then vacuum freeze-dried to obtain purple cabbage anthocyanin powder. Wherein, the acidified ethanol is a mixture of hydrochloric acid and absolute ethanol with a volume ratio of 15:85, and the concentration of the hydrochloric acid aqueous solution is 0.5 mol / L. The ultrasonic frequency is 10 kHz, the power is 20 watts, the ultrasonic mode is 2 seconds on / 2 seconds off, and the ultrasonic time is 10 minutes. The centrifugation speed is 6000 rpm, centrifugation is 10 minutes, and the centrifugation temperature is 4°C. The rotary steaming temperature is 45° C., and the rotation speed is 15 rpm. Vacuum freeze-drying is at a freezing temperature of -40°C and an air pressure of 2...

Embodiment 2

[0034] (1) Preparation of purple cabbage anthocyanins: 10 g of purple cabbage was crushed and added to 100 mL of acidified ethanol, ultrasonically extracted, and centrifuged to obtain a purple cabbage anthocyanin solution. The obtained solution was rotary evaporated, placed at -80°C for 12-48 hours, and then vacuum freeze-dried to obtain purple cabbage anthocyanin powder. Wherein, the acidified ethanol is a mixture of hydrochloric acid and absolute ethanol with a volume ratio of 15:85, and the concentration of the hydrochloric acid aqueous solution is 0.5 mol / L. The ultrasonic frequency is 10 kHz, the power is 20 watts, the ultrasonic mode is 2 seconds on / 2 seconds off, and the ultrasonic time is 10 minutes. The centrifugation speed is 6000 rpm, centrifugation is 10 minutes, and the centrifugation temperature is 4°C. The rotary steaming temperature is 45° C., and the rotation speed is 15 rpm. Vacuum freeze-drying is at a freezing temperature of -40°C and an air pressure of 2...

Embodiment 3

[0039] (1) Preparation of purple cabbage anthocyanins: 10 g of purple cabbage was crushed and added to 100 mL of acidified ethanol, ultrasonically extracted, and centrifuged to obtain a purple cabbage anthocyanin solution. The obtained solution was rotary evaporated, placed at -80°C for 12-48 hours, and then vacuum freeze-dried to obtain purple cabbage anthocyanin powder. Wherein, the acidified ethanol is a mixture of hydrochloric acid and absolute ethanol with a volume ratio of 15:85, and the concentration of the hydrochloric acid aqueous solution is 0.5 mol / L. The ultrasonic frequency is 10 kHz, the power is 20 watts, the ultrasonic mode is 2 seconds on / 2 seconds off, and the ultrasonic time is 10 minutes. The centrifugation speed is 6000 rpm, centrifugation is 10 minutes, and the centrifugation temperature is 4°C. The rotary steaming temperature is 45° C., and the rotation speed is 15 rpm. Vacuum freeze-drying is at a freezing temperature of -40°C and an air pressure of 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com