Silica gel swimming cap pad printing process

A silicone and pad printing technology, applied in the field of swimming caps, can solve the problems of wearing hot, airtight, easy to fade, etc., and achieve the effect of improving acid and alkali resistance, prolonging service life, and improving user experience.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

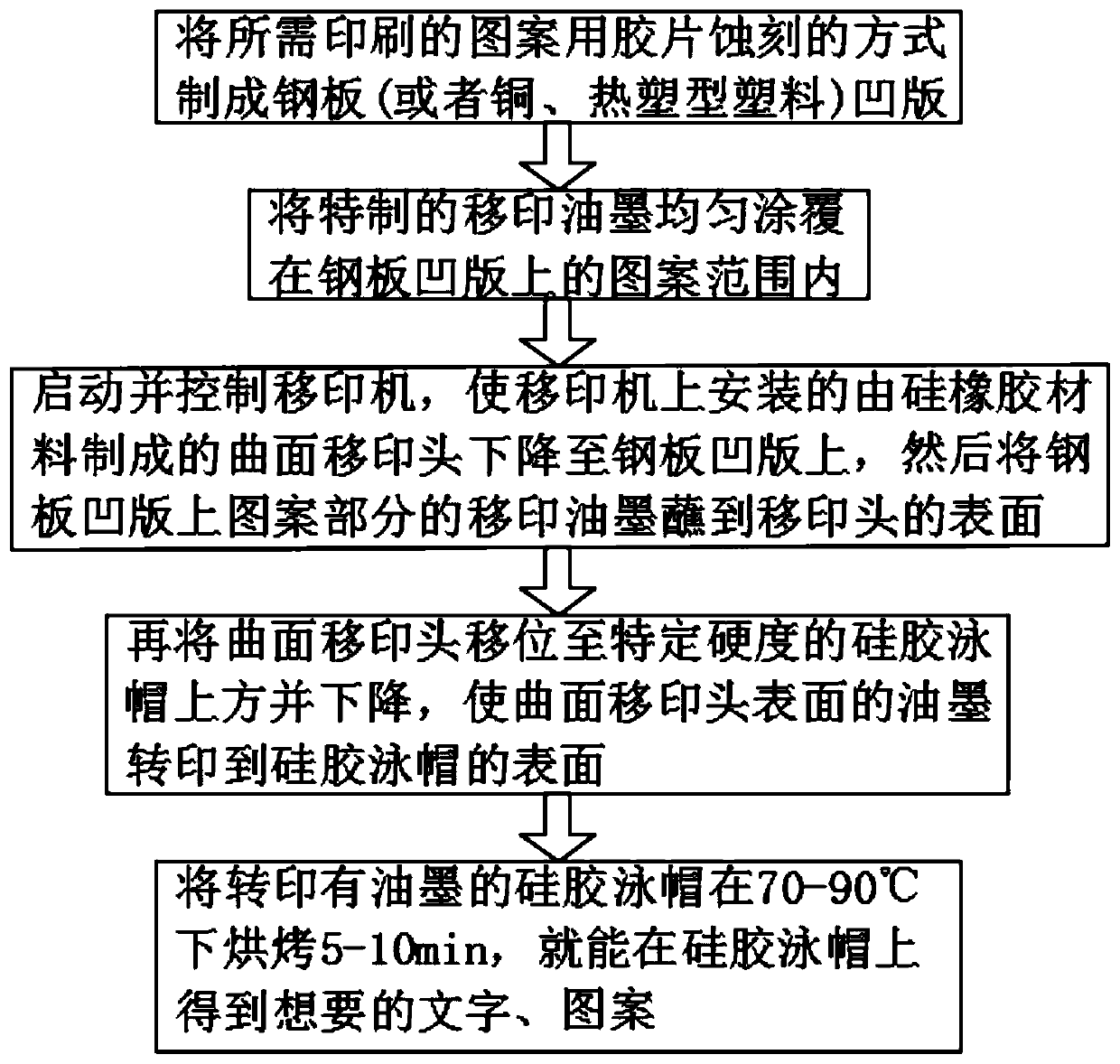

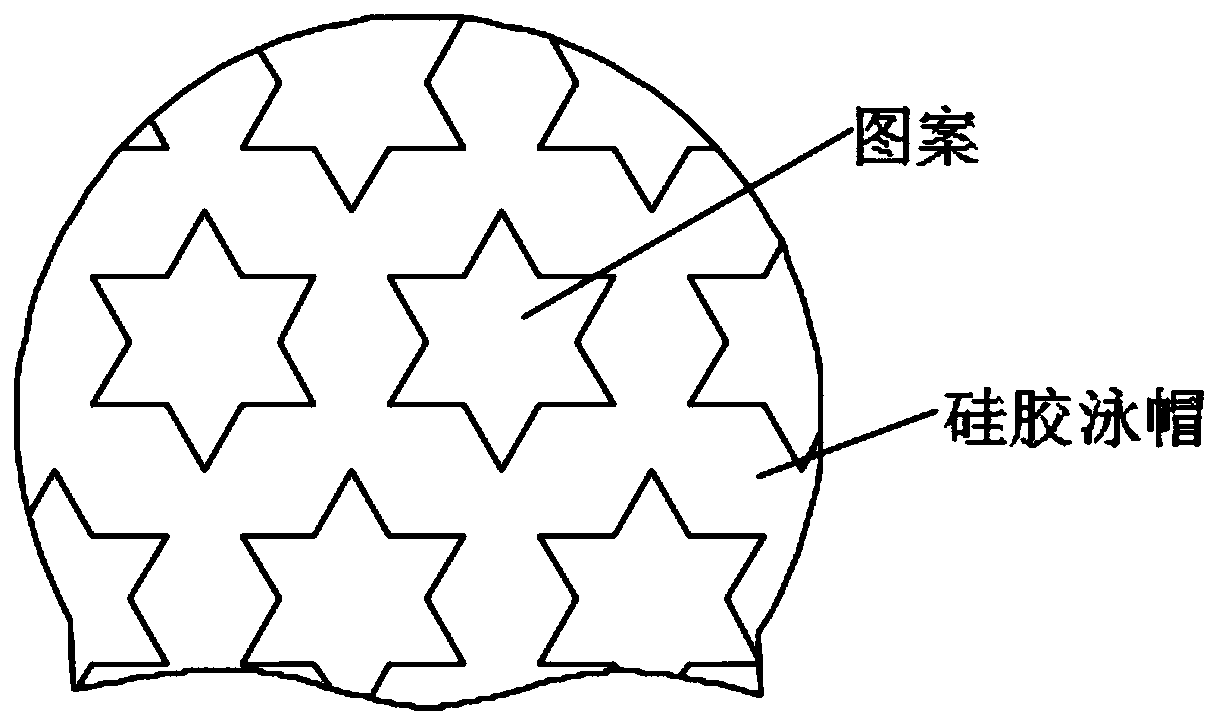

[0038] see Figure 1-2 , a silicone swimming cap pad printing process, comprising the following steps:

[0039] S1: Etching the pattern to be printed into a steel plate intaglio;

[0040] S2: Apply the special pad printing ink evenly within the pattern range on the steel gravure;

[0041] S3: Start and control the pad printing machine, so that the curved pad printing head made of silicone rubber material installed on the pad printing machine is lowered onto the steel plate gravure, and then the pad printing ink of the pattern part on the steel plate gravure is dipped on the surface of the pad printing head ;

[0042] S4: Then move the curved surface printing head above the silicone swimming cap with a specific hardness and lower it, so that the ink on the surface of the curved surface printing head is transferred to the surface of the silicone swimming cap;

[0043] S5: Baking the silicone swimming cap with the ink transferred at 70°C for 10 minutes, you can get the desired...

Embodiment 2

[0045] see Figure 1-2 , a silicone swimming cap pad printing process, comprising the following steps:

[0046] S1: Etching the pattern to be printed into a steel plate intaglio;

[0047] S2: Apply the special pad printing ink evenly within the pattern range on the steel gravure;

[0048] S3: Start and control the pad printing machine, so that the curved pad printing head made of silicone rubber material installed on the pad printing machine is lowered onto the steel plate gravure, and then the pad printing ink of the pattern part on the steel plate gravure is dipped on the surface of the pad printing head ;

[0049] S4: Then move the curved surface printing head above the silicone swimming cap with a specific hardness and lower it, so that the ink on the surface of the curved surface printing head is transferred to the surface of the silicone swimming cap;

[0050] S5: Baking the silicone swimming cap with the ink transferred at 80°C for 8 minutes, you can get the desired ...

Embodiment 3

[0052] see Figure 1-2 , a silicone swimming cap pad printing process, comprising the following steps:

[0053] S1: Etching the pattern to be printed into a steel plate intaglio;

[0054] S2: Apply the special pad printing ink evenly within the pattern range on the steel gravure;

[0055] S3: Start and control the pad printing machine, so that the curved pad printing head made of silicone rubber material installed on the pad printing machine is lowered onto the steel plate gravure, and then the pad printing ink of the pattern part on the steel plate gravure is dipped on the surface of the pad printing head ;

[0056] S4: Then move the curved surface printing head above the silicone swimming cap with a specific hardness and lower it, so that the ink on the surface of the curved surface printing head is transferred to the surface of the silicone swimming cap;

[0057] S5: Baking the silicone swimming cap with the ink transferred at 90°C for 5 minutes, you can get the desired ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com