Moisture-absorbent and quick-drying sportswear fabric and production method thereof

A technology for sportswear and fabrics, applied in rayon manufacturing, fabric surface trimming, textile material processing, etc., and can solve very few problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

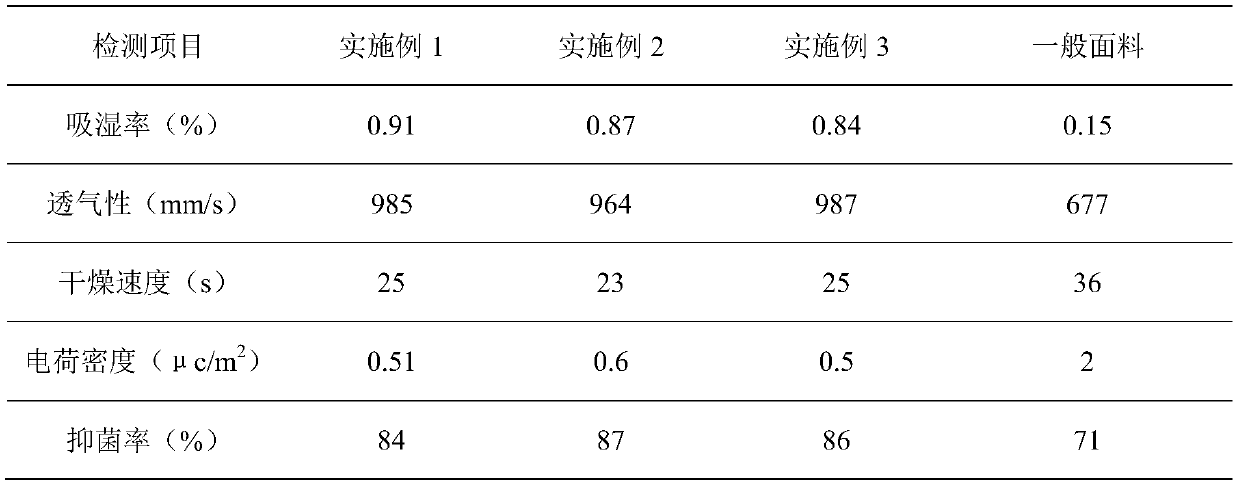

Examples

Embodiment 1

[0022] This embodiment is to prepare a kind of moisture absorption, quick-drying sportswear fabric, comprises following process step:

[0023] 1) Bamboo fiber treatment: the bamboo fiber used in the present embodiment preferably uses Lyocell bamboo fiber, because its single fiber strength is close to polyester, it is suitable as sportswear fabric. Because Lyocell bamboo fiber is a bamboo pulp fiber, its surface is relatively smooth, and contains a certain amount of impurities, and its initial modulus is large, which is not conducive to blending with other fibers. Therefore, it needs to be treated first: first, the bamboo fiber is immersed in the complex enzyme solution of pH = 6-7 for enzyme treatment, the bath ratio is 1:50, the treatment temperature is 65-70°C, and the treatment time is 60-70min; then, Take it out and wash it with hot water at 50-60°C for 2-3 times; then wash it with cold water for 3 times; finally put it in an oven to dry and set aside.

[0024] In the pre...

Embodiment 2

[0032] This embodiment also prepares a kind of moisture-absorbing, quick-drying sportswear fabric. The warp is obtained by blending 48 parts of Lyocell bamboo fiber, 15 parts of hemp fiber, 10 parts of chitin fiber and 1 part of silver fiber in parts by weight. The weft is obtained by blending 30 parts of modified polyester fiber, 18 parts of jade fiber, 10 parts of coolmax fiber and 5 parts of aloe fiber in parts by weight. All the other steps are the same as in Example 1.

Embodiment 3

[0034] The present embodiment is hygroscopic, quick-drying sportswear fabric, and its warp is obtained by blending 45 parts by weight of Lyocell bamboo fiber, 14 parts of hemp fiber, 9 parts of chitin fiber, and 0.8 part of silver fiber, and its weft is obtained by weight In terms of parts, 28 parts of modified polyester fiber, 16 parts of jade fiber, 8 parts of coolmax fiber and 3 parts of aloe fiber are obtained by blending. All the other steps are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com