Energy-saving and environment-friendly grain dryer and using method thereof

A grain dryer, energy-saving and environment-friendly technology, applied in the direction of grain drying, drying machine, drying solid materials, etc., can solve the problems of air pollution and achieve high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

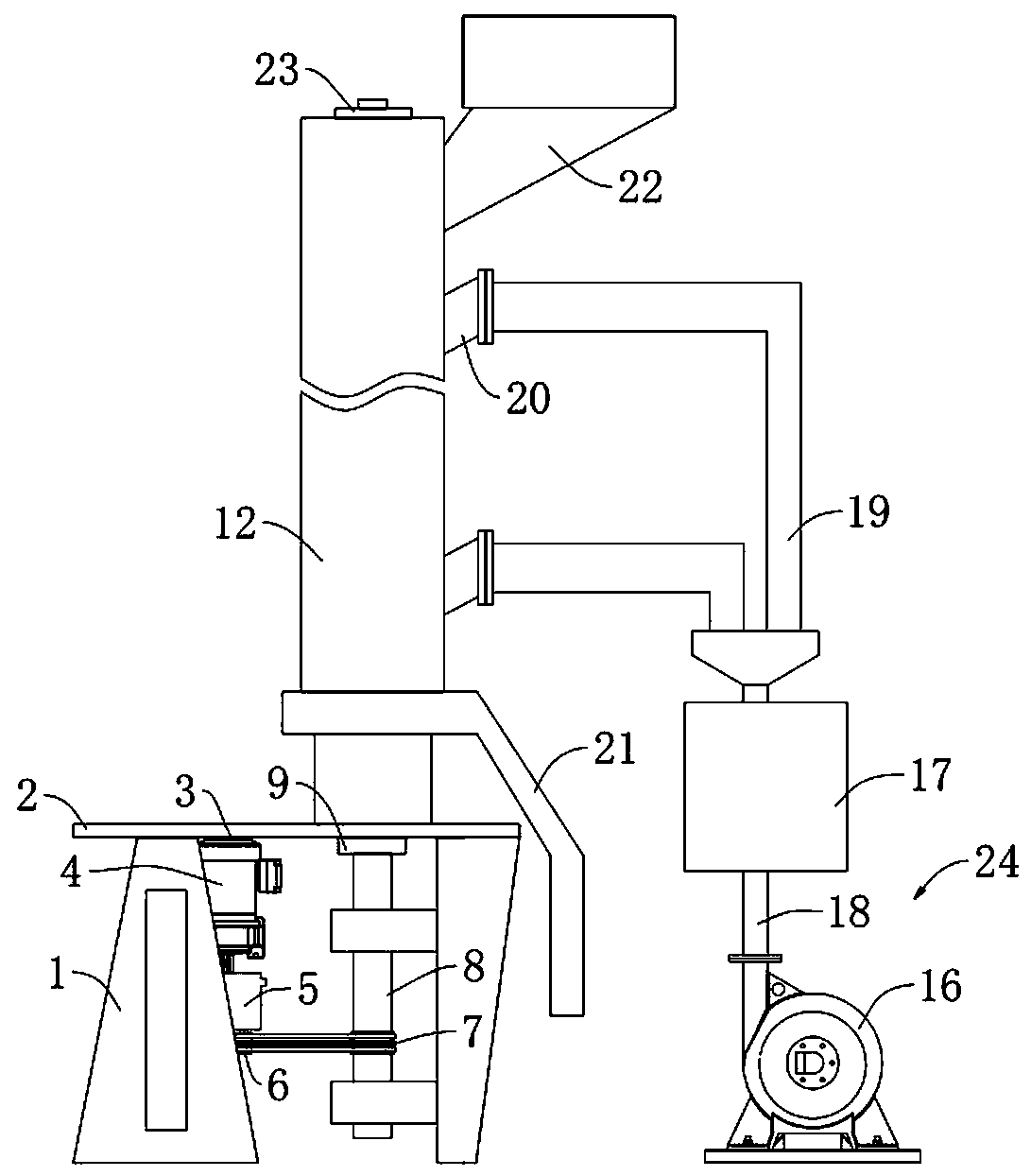

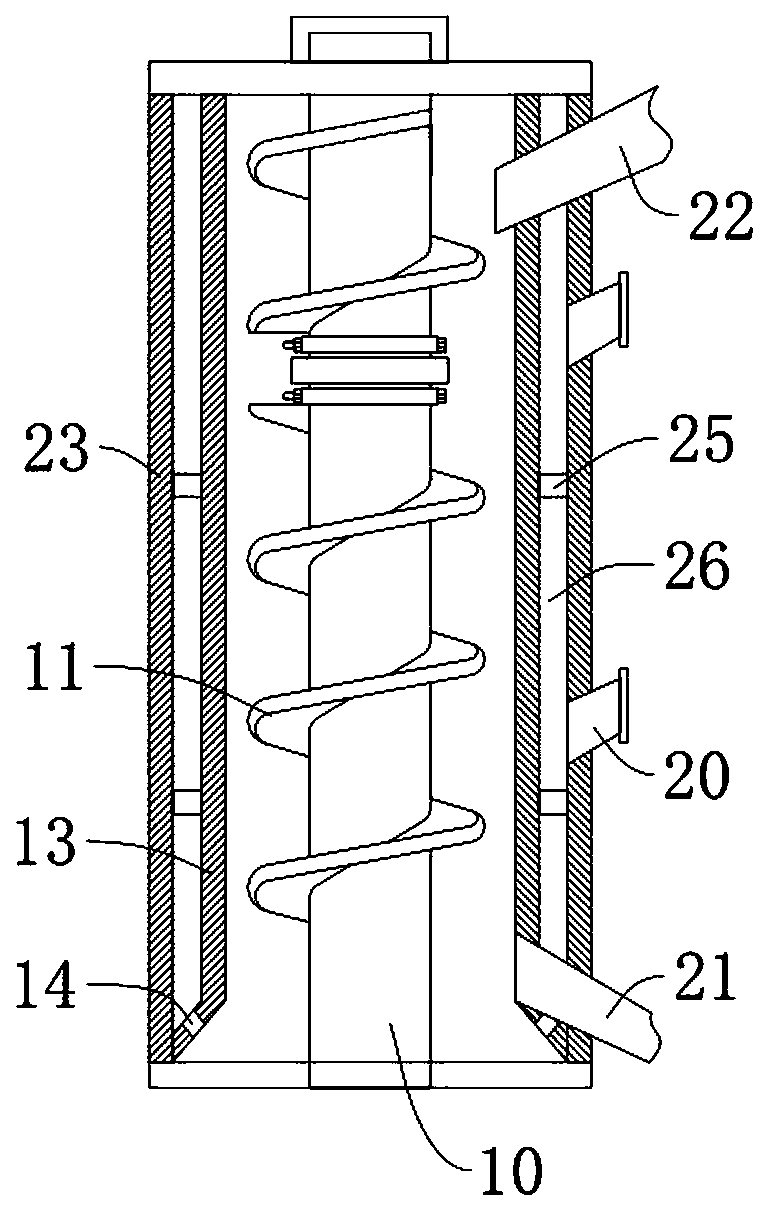

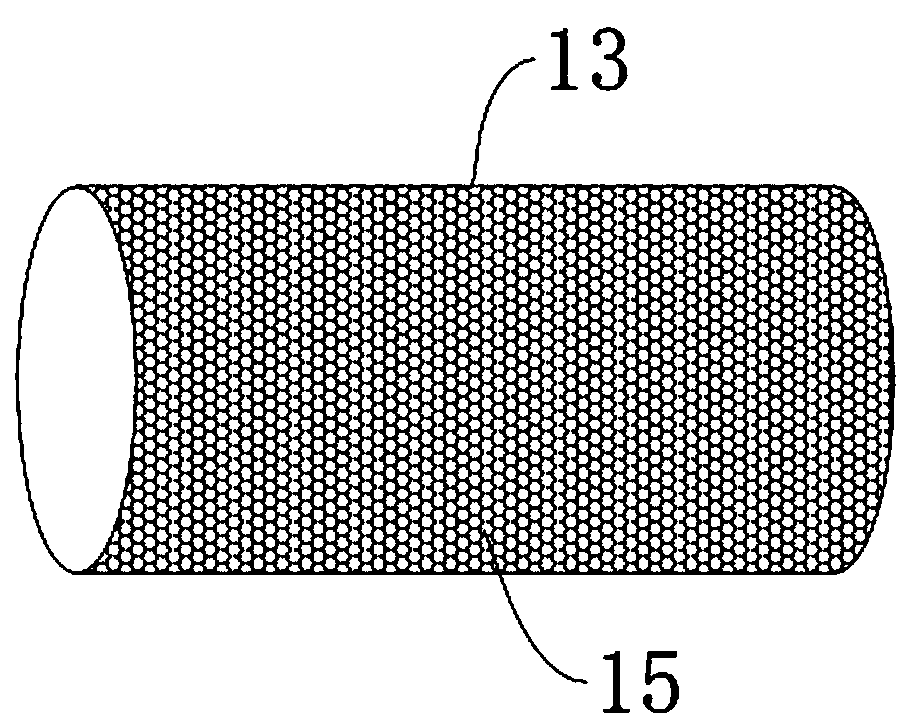

[0025] Please refer to the attached Figure 1-3 , an energy-saving and environment-friendly grain dryer, comprising a bracket 1, a support horizontal plate 2 is fixedly welded on the top of the support 1, and a motor base 3 is fixedly connected to the lower side of the support horizontal plate 2 through bolts, and the set support The horizontal plate 2 is convenient to install and fix the motor base 3, the motor 4 is fixedly installed under the motor base 3, the output end of the motor 4 is connected with a reducer 5, and the output end of the reducer 5 is connected with a belt Disk 6, the other side below the support horizontal plate 2 is fixedly installed with a shaft sleeve 9 through a vertical plate, and a drive shaft 8 is installed in the shaft sleeve 9. The drive shaft 8 and the belt pulley 6 are driven by a belt 7 connection, the top of the support horizontal plate 2 is fixedly welded with an outer cylinder 12, the inside of the outer cylinder 12 is provided with an inn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com