Wolf pack algorithm-based multi-target disassembly line setting method under spatial constraint

A wolf pack algorithm and space-constrained technology, applied in computing, computing models, instruments, etc., can solve problems such as increased difficulty, large size range of parts, subjective influence of decision makers, etc., to achieve strong search ability and robustness, Improve space utilization and realize the effect of standardized management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

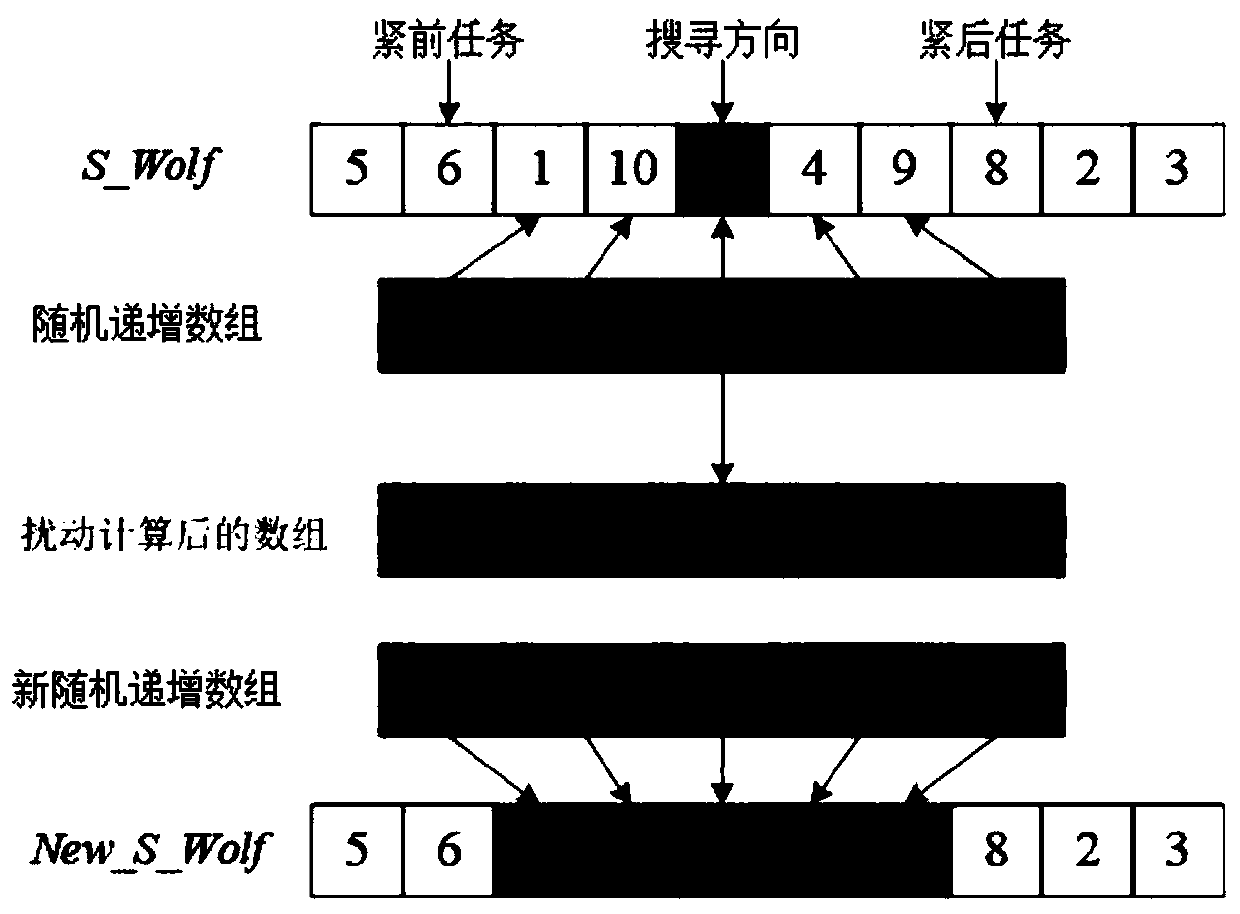

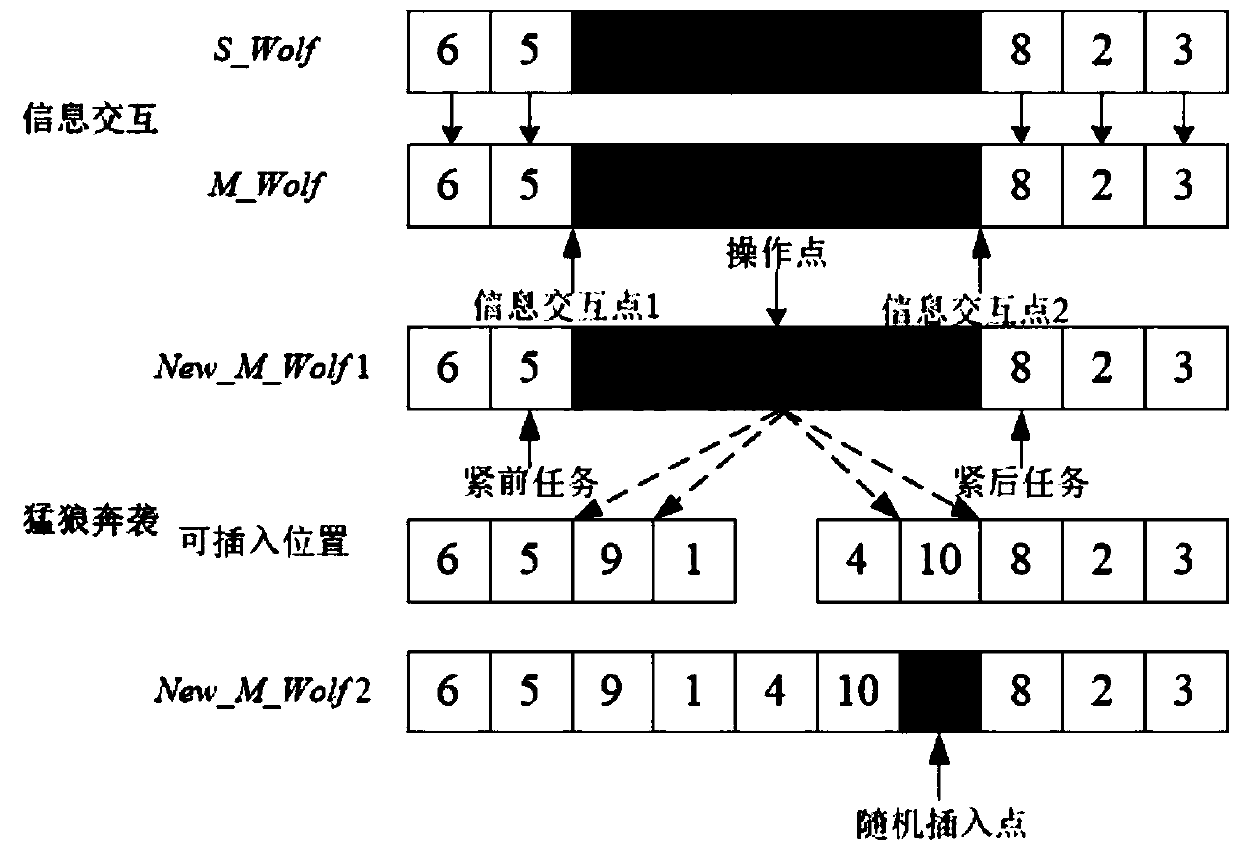

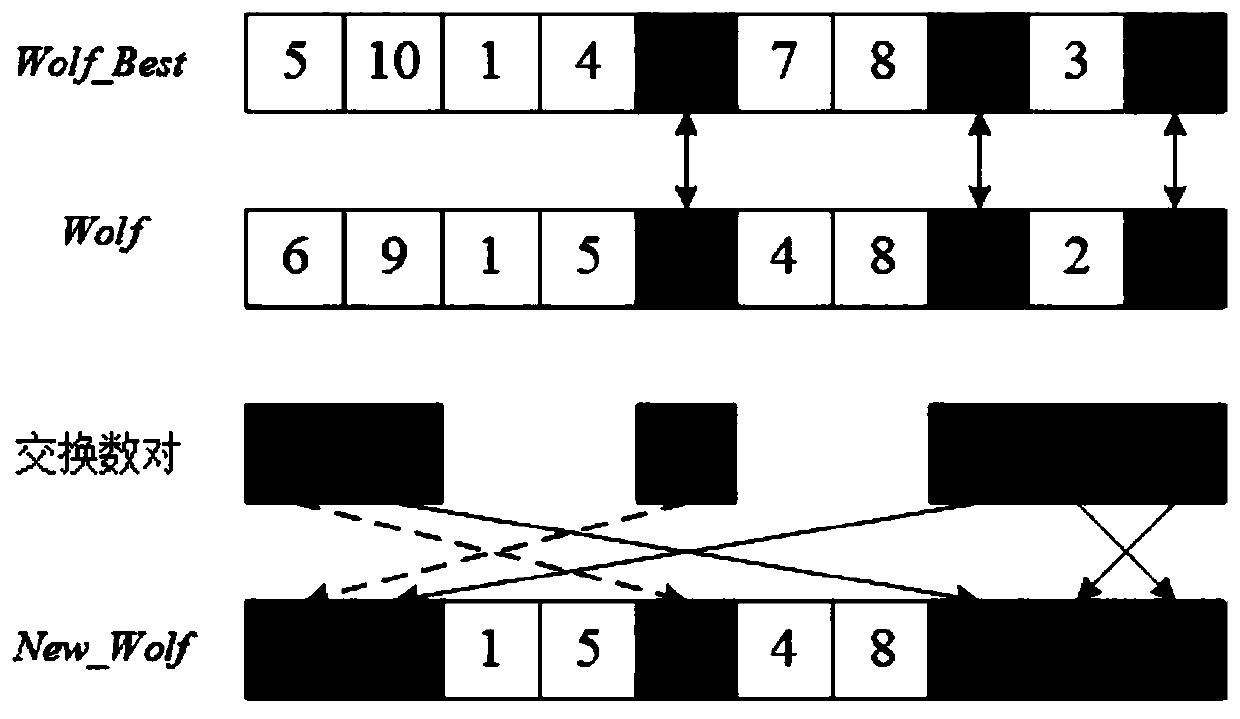

Method used

Image

Examples

Embodiment 1

[0154] The disassembly information of a certain printer is shown in Table 1, including n=55 disassembly tasks. The disassembly task attributes include disassembly time (in seconds), hazard attributes (1 means hazardous, 0 means non-hazardous), parts and components Area and dismantling cost per unit time (unit is yuan / second); the priority relationship of dismantling tasks is as follows Figure 5 As shown, according to this figure, the dismantling task priority relationship matrix TP=(P ij ) 55*55 , for example, disassembly task 4 is the immediate predecessor task of disassembly task 5, so P 4,5 = 1, P 5,4 =0; Z=4 in the demolition information matrix, that is, KB=(Q i1 , Q i2 , Q i3 , Q i4 ), where Q i1 is the disassembly time, Q i2 is the hazard attribute, Q i3 is the area of disassembled parts, Q i4 is the dismantling cost per unit time.

[0155] Table 1

[0156]

[0157] Considering the market demand and the actual dismantling time comprehensively, it is det...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com