Meat proteolysis and enzymatic hydrolysis equipment, meat tenderization method and computer-readable storage medium

A technology of proteolytic enzyme and vegetable protease, which is applied in the fields of meat tenderization, computer readable storage media, and meat proteolysis and enzymatic equipment, which can solve the problem of excessive tenderization of meat, affecting the taste of users, and poor pertinence of meat And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

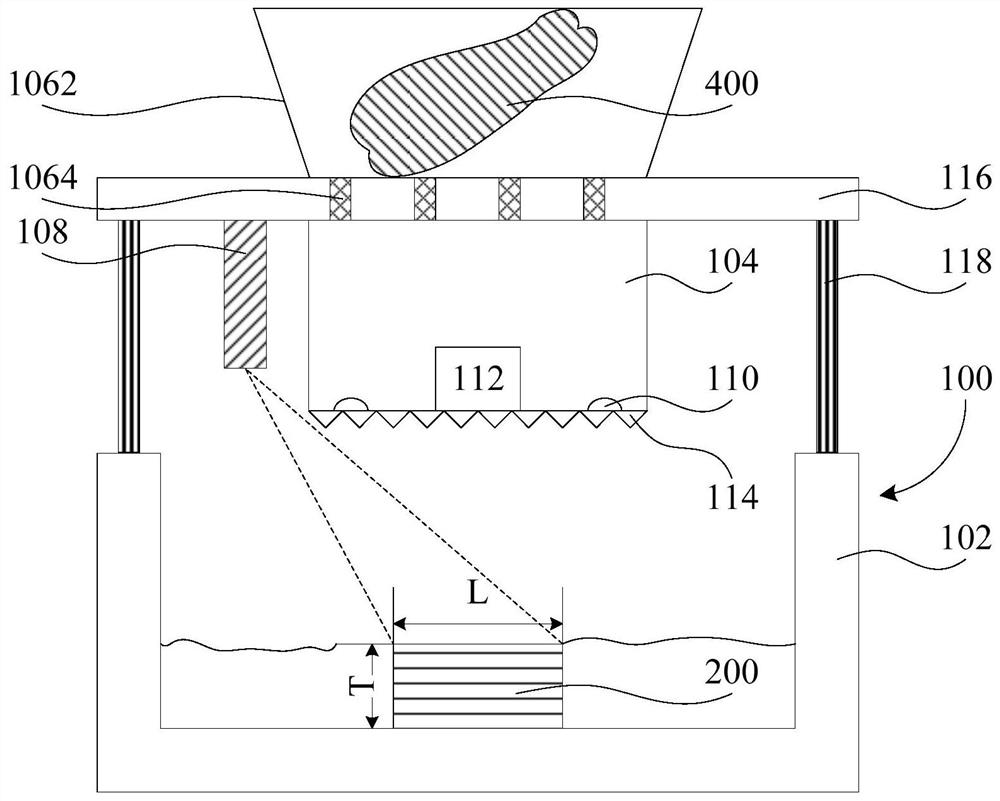

[0069] figure 1 A schematic diagram showing the cross-sectional structure of a meat proteolytic enzymatic hydrolysis device according to an embodiment of the present invention.

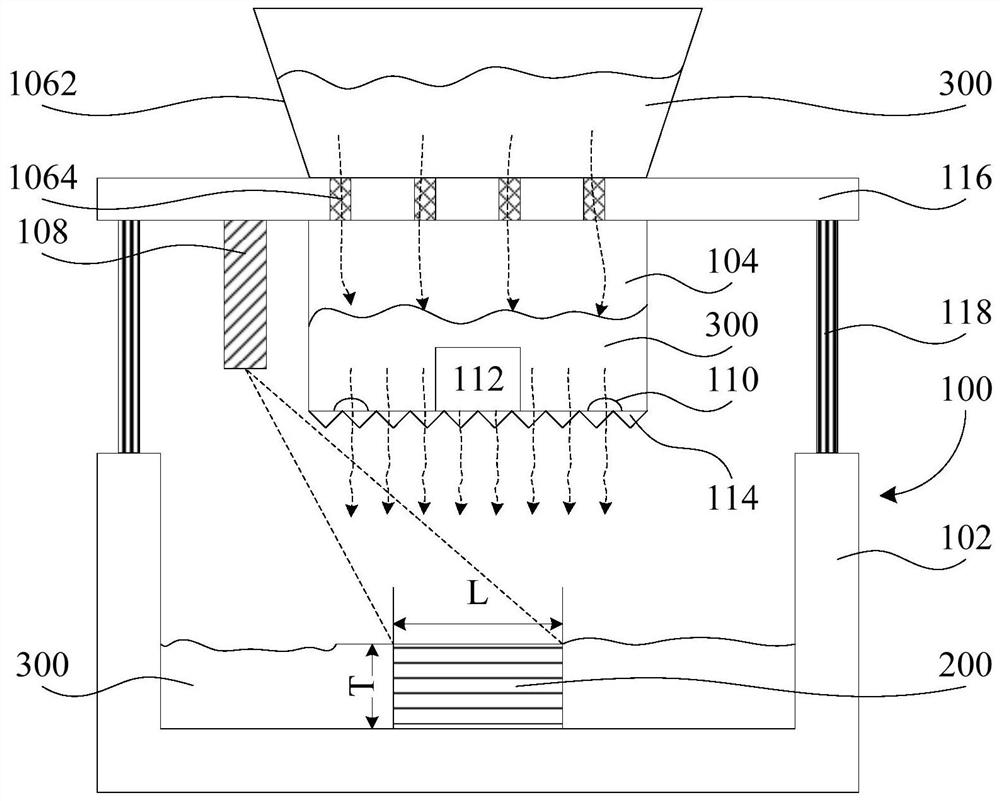

[0070] figure 2 A schematic diagram showing a cross-sectional structure of a meat proteolytic enzymatic hydrolysis device according to another embodiment of the present invention.

[0071] like figure 1 and figure 2 As shown, the meat material proteolytic and enzymatic hydrolysis equipment 100 according to an embodiment of the present invention includes: a accommodating part 102 for placing the meat material to be tenderized; The inner panels of the raw materials are arranged opposite to each other, and are used for directional hammer pressing treatment of the meat; the fruit and vegetable protease generator is connected to the accommodating part 102 and is arranged to grind or press the fruit and vegetable products 400 to obtain the fruits and vegetables containing proteolytic enzymes. Juice 30...

Embodiment 2

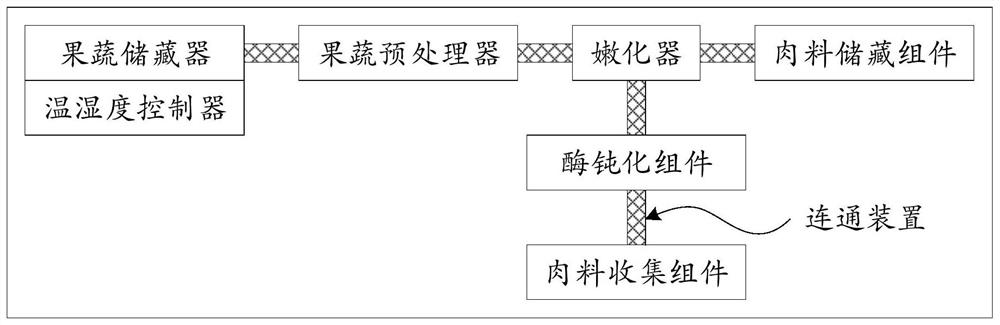

[0099] image 3 A schematic block diagram of a meat proteolytic enzymolysis device according to another embodiment of the present invention is shown.

[0100] like image 3 shown in figure 1 and figure 2 Based on the structure of the meat material proteolytic enzymolysis equipment shown in the first embodiment, the meat material tenderization method shown in the second embodiment includes the following steps:

[0101] (1) The same area or multiple areas in the fruit and vegetable storage container of the fruit and vegetable protease generator store various fruits, such as papaya (papain), pineapple (bromelain) and kiwi (kiwifruit protease), etc. Among the above-mentioned natural proteolytic enzymes , with papain the most active and the most widely used.

[0102] Among them, during the storage process of fruits, it is recommended to keep the ambient temperature at 4°C to 8°C. If the temperature is too high, the fruit will be easily spoiled and deteriorated, which is not co...

Embodiment 3

[0113] Figure 4 A schematic flow chart of a meat tenderization method according to an embodiment of the present invention is shown.

[0114] like Figure 4 As shown, the method for tenderizing meat material according to an embodiment of the present invention includes: step S402, in response to an instruction requesting to tenderize the meat material, controlling the grinding or pressing of fruit and vegetable products to obtain a quantitative amount of protein containing protein The fruit and vegetable juice of hydrolase; Step S404, the fruit and vegetable juice is diverted into the container for holding the meat material, wherein the proteolytic enzyme can enzymatically decompose the myofibrils and / or connective tissue in the meat material.

[0115] In this technical solution, the fruit and vegetable products are controlled to be ground or pressed in response to an instruction to tenderize the meat, so as to obtain a certain amount of fruit and vegetable juice containing pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com