Ceramic fiber heat insulating material with which aluminum film is covered

A technology of ceramic fiber and thermal insulation material, which is applied in casting melt containers, manufacturing tools, metal processing equipment, etc., can solve the problems of easy warpage deformation, poor thermal insulation performance, deterioration of thermal insulation and sealing performance, etc., and achieves increased bonding Powerful, easy-to-bake effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

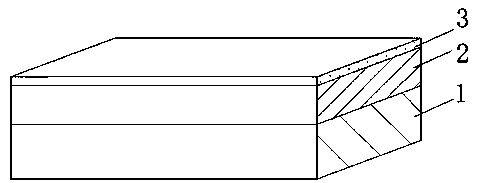

[0027] A ceramic fiber insulation material covered with an aluminum film, comprising a non-heating layer 1, the upper surface of the non-heating layer 1 is fixedly connected with a heating layer 2, and the surface of the heating layer 2 is fixedly connected with an aluminum film 3; the non-heating layer 1 is composed of The raw materials are composed of the following percentages: ceramic fiber 55%, sol binder 10%, starch 8%, clay 20% and silica powder 7%; the heating layer 2 is composed of the following percentages of raw materials: refractory fiber 50%, clay 15%, 8% starch, 2% organic binder, 1% inorganic binder, 7% alumina powder, 4% corundum powder, 2% heat insulation additive and 11% sol binder; the aluminum film 3 is an aluminum oxide film.

[0028] The refractory fiber is a high-alumina refractory fiber, with industrial alumina, high-purity silica and quartz sand as the main raw materials, and the batch materials are melt-blown or spun into fibers to obtain high-purity gl...

Embodiment 2

[0039] A ceramic fiber insulation material covered with an aluminum film, comprising a non-heating layer 1, the upper surface of the non-heating layer 1 is fixedly connected with a heating layer 2, and the surface of the heating layer 2 is fixedly connected with an aluminum film 3; the non-heating layer 1 is composed of The raw materials are composed of the following percentages: ceramic fiber 55%, sol binder 10%, starch 8%, clay 20% and silica powder 7%; the heating layer 2 is composed of the following percentages of raw materials: refractory fiber 55%, clay 10%, 8% starch, 2% organic binder, 1% inorganic binder, 7% alumina powder, 4% corundum powder, 2% heat insulation additive and 11% sol binder; the aluminum film 3 is an aluminum oxide film.

[0040] The refractory fiber is a high-alumina refractory fiber, with industrial alumina, high-purity silica and quartz sand as the main raw materials, and the batch materials are melt-blown or spun into fibers to obtain high-purity gl...

Embodiment 3

[0051] A ceramic fiber insulation material covered with an aluminum film, comprising a non-heating layer 1, the upper surface of the non-heating layer 1 is fixedly connected with a heating layer 2, and the surface of the heating layer 2 is fixedly connected with an aluminum film 3; the non-heating layer 1 is composed of The raw materials are composed of the following percentages: ceramic fiber 55%, sol binder 10%, starch 8%, clay 20% and silica powder 7%; the heating layer 2 is composed of the following percentages of raw materials: refractory fiber 53%, clay 12%, 8% starch, 2% organic binder, 1% inorganic binder, 7% alumina powder, 4% corundum powder, 2% heat insulation additive and 11% sol binder; the aluminum film 3 is an aluminum oxide film.

[0052] The refractory fiber is a high-alumina refractory fiber, with industrial alumina, high-purity silica and quartz sand as the main raw materials, and the batch materials are melt-blown or spun into fibers to obtain high-purity gl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com