Foamed polypropylene composite sheet and preparation method thereof

A foamed polypropylene and composite sheet technology, applied in the field of materials, can solve problems such as VOC cannot be realized, VOC can be reduced, and cannot be known, and the effects of avoiding collapse and shrinkage, increasing foaming ratio, and uniform raw materials can be achieved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

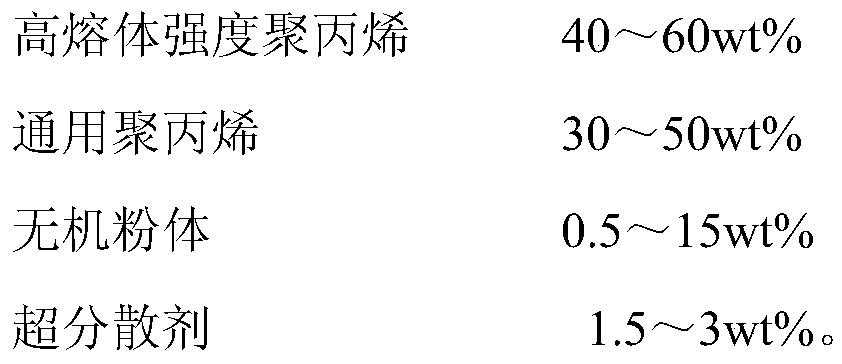

[0050] In this embodiment, the following methods and ingredients are used to prepare a foamed polypropylene composite sheet:

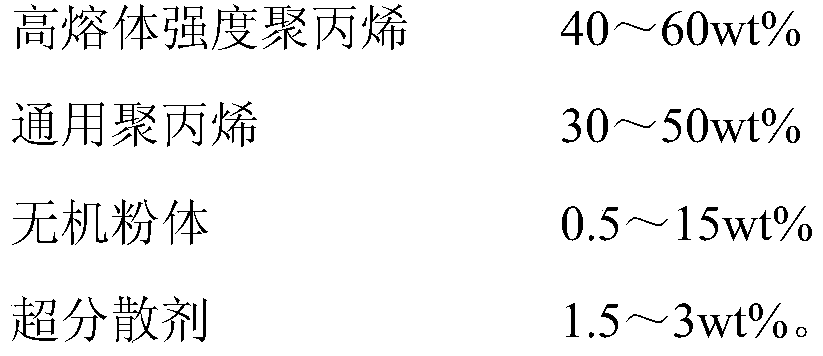

[0051] (1) The weighed attapulgite with a length-to-diameter ratio of 5:1 and a particle size of 30μm and Lubote YY-502 are stirred at high speed for 10 minutes, and then the weighed high-melt strength polypropylene and EPS30R are polymerized. Propylene was added to it and stirred at low speed for 5 minutes, and the mixture was extruded and pelletized at 240°C to obtain a special foam material. The weight ratios of the ingredients in the special foam material were:

[0052]

[0053] (2) Add the special foaming material of step (1) into the supercritical foaming screw extruder, and accurately inject CO in the metering section 2 Liquid, control the injection volume to be 3% of the foaming special material, the foaming ratio is 5, adjust the temperature of the extruder to 140℃, and adjust the pressure to 8.0MPa to make CO 2 It is in a supercritical state. After...

Embodiment 2

[0059] In this embodiment, the following methods and ingredients are used to prepare a foamed polypropylene composite sheet:

[0060] (1) The weighed attapulgite with a length-to-diameter ratio of 7:1 and a particle size of 10μm and Lubote YY-702 are stirred at high speed for 5 minutes, and then the weighed high-melt strength polypropylene and EPS30R are polymerized. Propylene was added to it and stirred at low speed for 3 minutes, and the mixture was extruded and pelletized at 220°C to obtain a special foaming material. The weight ratios of the components in the special foaming material are:

[0061]

[0062] (2) Add the special foaming material of step (1) into the supercritical foaming screw extruder, and accurately inject CO in the metering section 2 Liquid, control the injection volume to be 3% of the foaming special material, the foaming ratio is 5 times, adjust the temperature of the extruder to 240℃, and adjust the pressure to 20MPa to make CO 2 It is in a supercritical stat...

Embodiment 3

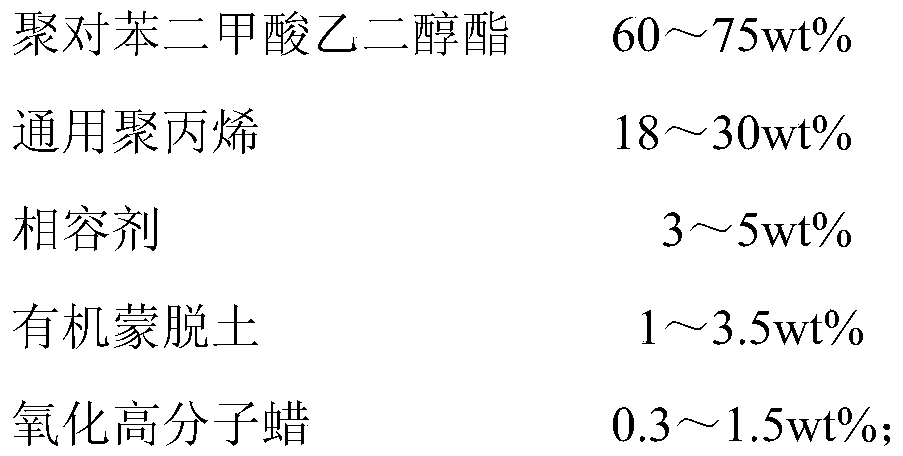

[0069] In this embodiment, the following methods and ingredients are used to prepare a foamed polypropylene composite sheet:

[0070] (1) The weighed wollastonite with a length-to-diameter ratio of 18:1 and a particle size of 50μm, and the ultra-dispersants Lubote YY-502 and YY-702 (ratio 1:3) are stirred at high speed for 10 minutes, and then Add the weighed high-melt strength polypropylene and EPS30R polypropylene into them and stir at low speed for 5 minutes to obtain the mixture, extrude and granulate at 230°C to obtain the foaming special material. The weight ratio of each component in the foaming special material is respectively for:

[0071]

[0072] (2) Add the special foaming material of step (1) into the supercritical foaming screw extruder, and accurately inject CO in the metering section 2 Liquid, control the injection volume to be 0.3% of the special foaming material, the foaming ratio is 2, adjust the temperature of the extruder to 170℃, and adjust the pressure to 12....

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| flexural modulus | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com