Continuous production process of polydimethylsiloxane

A technology for the preparation of polydimethylsiloxane, which is applied in the field of continuous preparation of polydimethylsiloxane, and can solve the problem of cumbersome polydimethylsiloxane process steps, low product quality, and long reaction time and other issues to achieve high production efficiency, lower production costs, and stable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

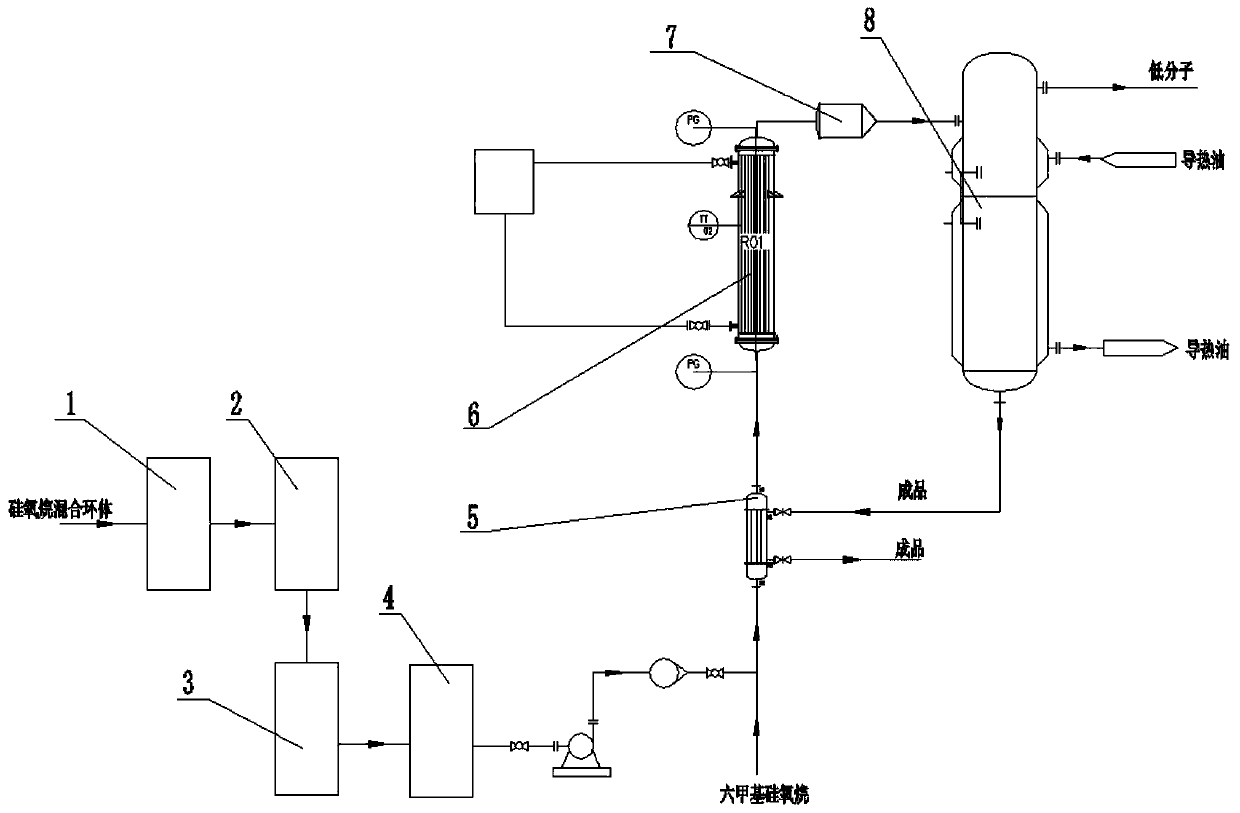

[0025] A continuous preparation process of polydimethylsiloxane, carried out as follows:

[0026] Raw material feed ratio is as follows:

[0027] Hexamethyldisiloxane: 5.8kg / h; siloxane mixed ring body 619kg / h; the mass ratio of hexamethyldisiloxane to siloxane mixed ring body is 1:106.7.

[0028] A. Raw material pretreatment: the siloxane mixed ring body is dehydrated through the thin film evaporator-1 and the desiccant fixed bed 2, and the metal ions are removed through the activated carbon fixed bed 3 and the ion exchange resin bed 4, and the thin-film evaporator-1 The operating temperature is 70°C and the vacuum degree is -0.08Mpa.

[0029] B. Preheating: Hexamethylsiloxane and siloxane mixed rings are mixed in a static mixer at a mass ratio of 1:106.7, and then enter the preheater 5 to preheat to 80°C.

[0030] C. Telomerization: After preheating, the material enters the tube reactor 6 for equilibrium reaction, and the tube is filled with cationic acid resin, the reacti...

Embodiment 2

[0036] Raw material feed ratio is as follows:

[0037] Hexamethyldisiloxane: 11kg / h; siloxane mixed ring body 614kg / h; the mass ratio of hexamethyldisiloxane to siloxane mixed ring body is 1:55.8.

[0038] A. Raw material pretreatment: the siloxane mixed ring body is dehydrated through the thin film evaporator-1 and the desiccant fixed bed 2, and the metal ions are removed through the activated carbon fixed bed 3 and the ion exchange resin bed 4, and the thin-film evaporator-1 The operating temperature is 70°C and the vacuum degree is -0.08Mpa.

[0039] B. Preheating: Hexamethylsiloxane and siloxane mixed rings are mixed in a static mixer at a mass ratio of 1:55.8, and then enter a preheater to preheat to 80°C.

[0040] C. Telomerization: After preheating, the material enters the tube reactor 6 for equilibrium reaction, and the tube is filled with cationic acid resin, the reaction temperature is 80°C, and the reaction residence time is 1 hour.

[0041] D. Purification: After...

Embodiment 3

[0046] Hexamethyldisiloxane: 9kg / h; siloxane mixed ring body 619kg / h; the mass ratio of hexamethyldisiloxane to siloxane mixed ring body is 1:68.7.

[0047] A. Raw material pretreatment: the siloxane mixed ring body is dehydrated through the thin film evaporator-1 and the desiccant fixed bed 2, and the metal ions are removed through the activated carbon fixed bed 3 and the ion exchange resin bed 4, and the thin-film evaporator-1 The operating temperature is 70°C and the vacuum degree is -0.08Mpa.

[0048] B. Preheating: Hexamethylsiloxane and siloxane mixed rings are mixed in a static mixer at a mass ratio of 1:68.7, and then enter a preheater to preheat to 80°C.

[0049] C. Telomerization: After preheating, the material enters the tube reactor 6 for equilibrium reaction, and the tube is filled with cationic acid resin, the reaction temperature is 80°C, and the reaction residence time is 1 hour.

[0050] D. Purification: After telomerization, the silicone oil passes through t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com