Preparation method of titanium-molybdenum alloy

A technology for titanium-molybdenum alloy and intermediate alloy, which is applied in the field of preparation of titanium-molybdenum alloy, can solve the problems of complex process, high melting point, affecting the preparation of qualified ingots, etc., and achieves the effect of simple process, uniform composition, and promotion of rapid and uniform melting.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0018] The embodiment of the present invention discloses a preparation method of a titanium-molybdenum alloy, comprising the following steps:

[0019] First, Ti powder and Mo powder are used as raw materials, and the mesh numbers of Ti powder and Mo powder are both greater than 200 mesh. The powder metallurgy method is used to perform powder mixing, isostatic pressing and sintering in sequence to prepare a Ti-Mo master alloy. Ti- The size of Mo master alloy is (30-50)×60×(250-280)mm. Among them, when mixing powder by powder metallurgy method, manual powder mixing and mechanical powder mixing are carried out sequentially, manual powder mixing is 3 to 6 times, mechanical powder mixing is 2 to 4 hours; 4h.

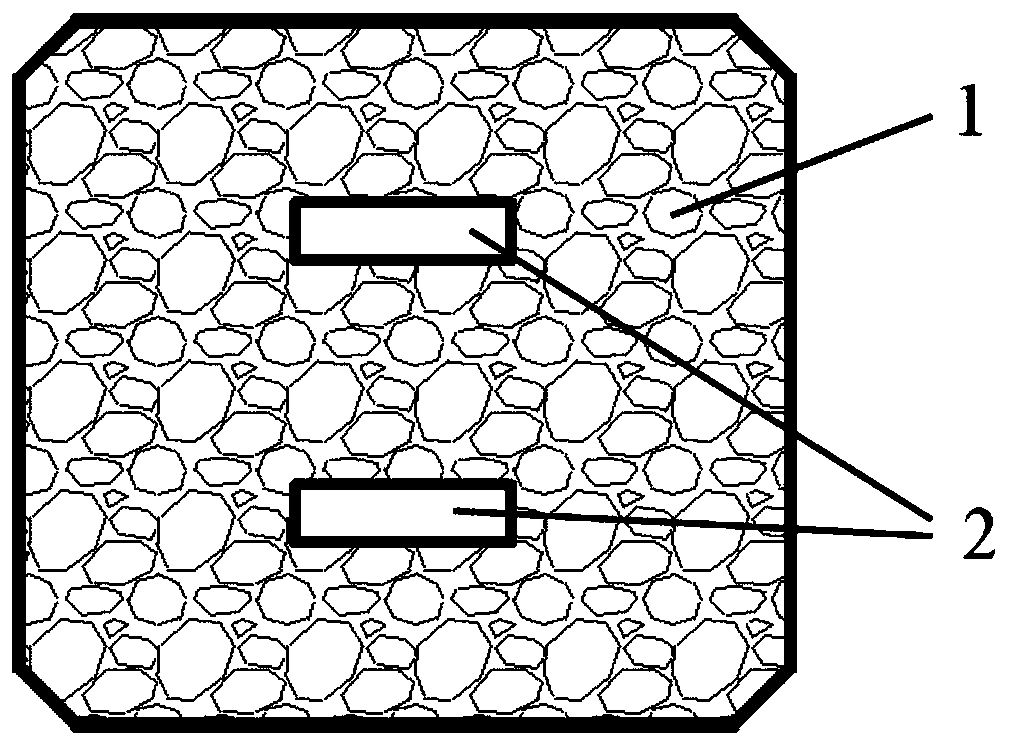

[0020] The Ti-Mo master alloy 2 and titanium sponge 1 are pressed, the particle size of the 0-grade or 1-grade sponge titanium particles is 3-12.7mm, and the electrode block is obtained and welded to form a consumable electrode; wherein, the sponge titanium is 0 Grade or gr...

Embodiment 1

[0029] The preparation method of the Ti-32Mo (wt%) alloy ingot: the raw materials are 0-grade or 1-grade sponge titanium, titanium powder and molybdenum powder. The particle size of titanium sponge is 3-12.7mm, and the titanium powder and molybdenum powder are both larger than 200 mesh. The Ti-Mo master alloy is prefabricated by powder metallurgy. The element ratio is Ti-80Mo (wt%), the unit weight is 5.65Kg, and there are 80 pieces in total. The measured size is: (40×60)mm×260mm. When pressing the consumable electrode block, pour 17Kg titanium sponge into the pressing mold three times, and add Ti-80Mo master alloy in the middle of every two times. The unit weight of the electrode block is 28.3Kg, and the external dimensions are □160×300mm, that is, a square blank with a side length of 160mm and a length of 300mm. A total of 40 electrode blocks were pressed, and according to the actual situation, every 10 electrode blocks were welded into a consumable electrode, and 4 consu...

Embodiment 2

[0031]The preparation method of the Ti-15Mo (wt%) alloy ingot: the raw materials are 0-grade or 1-grade sponge titanium, titanium powder and molybdenum powder. The particle size of titanium sponge is 3-12.7mm, and the titanium powder and molybdenum powder are both larger than 200 mesh. The Ti-Mo master alloy is prefabricated by powder metallurgy. The element ratio is Ti-60Mo (wt%), the unit weight is 3.7Kg, and there are 80 pieces in total. The measured size is: (30×60)mm×280mm. When pressing the consumable electrode block, pour 22.2Kg titanium sponge into the pressing mold three times, and add Ti-60Mo master alloy in the middle of every two times. The unit weight of the electrode block is 29.6Kg, and the external dimension is □160×300mm, that is, a square blank with a cross-sectional side length of 160mm. A total of 40 electrode blocks were pressed, and according to the actual situation, every 10 electrode blocks were welded into a consumable electrode, and 4 consumable el...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com