Al-Ga-In-Sn-Bi alloy for hydrogen production and application of Al-Ga-In-Sn-Bi alloy to fuel cell

An al-ga-in-sn, fuel cell technology, which is applied in the field of aluminum alloy hydrogen production, can solve the problems of insufficient transportation and storage, and achieve the effects of excellent hydrogen production performance, reduced production cost, and stable and gentle reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4

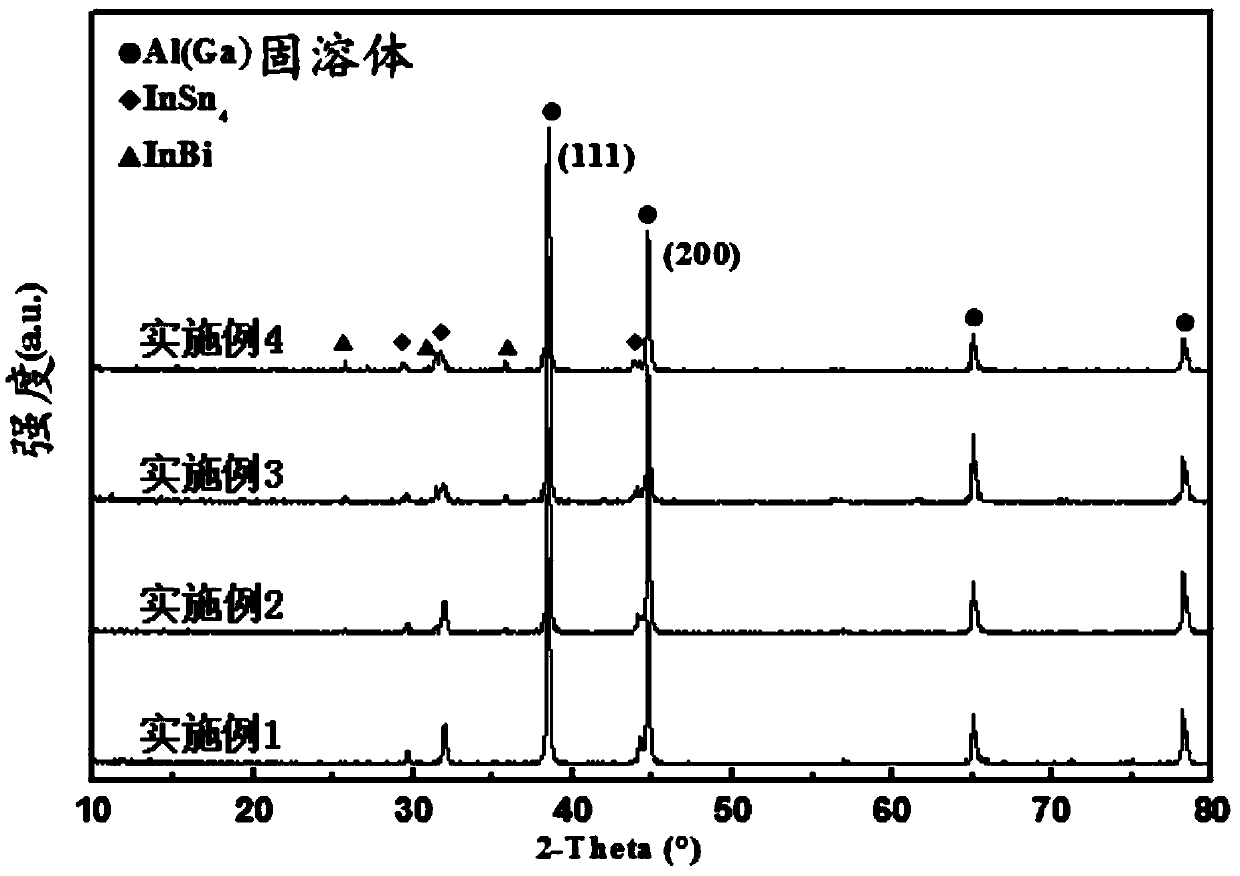

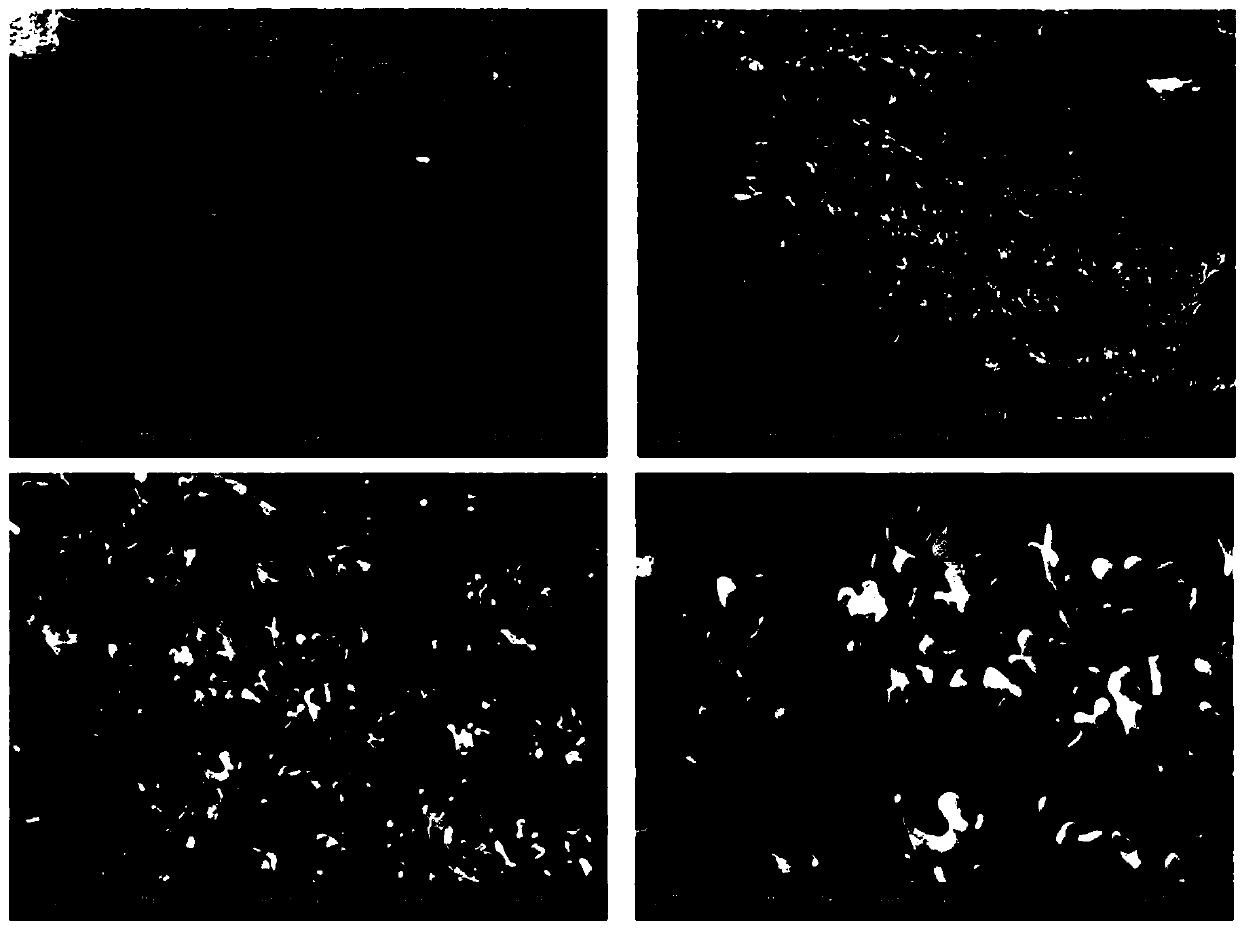

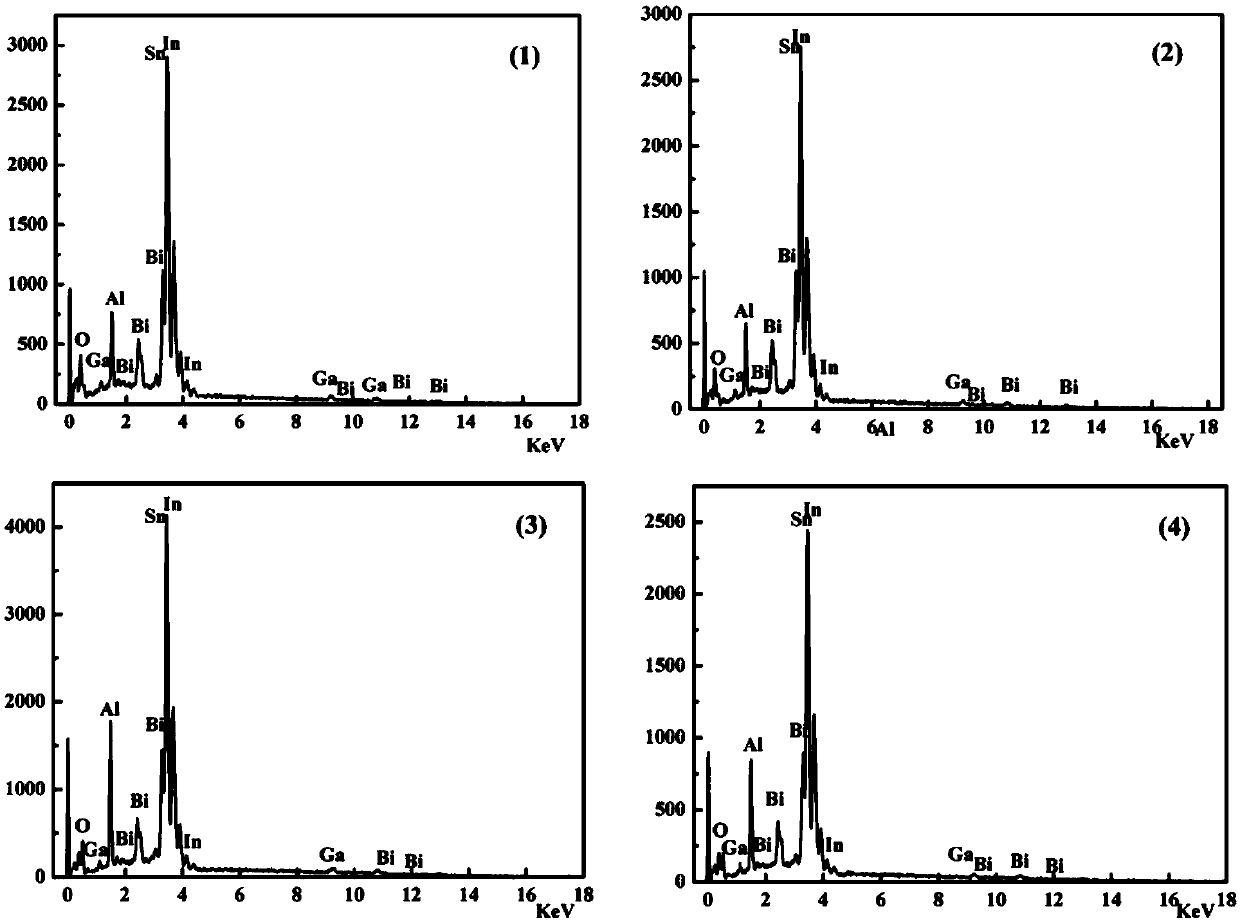

[0032] Preparation of Al-Ga-In-Sn-Bi Alloy

[0033] (1) The alloy composition is shown in Table 1:

[0034] Table 1 Al-Ga-In-Sn-Bi quinary alloy composition ratio (wt%)

[0035] Al Ga In sn Bi Matching ratio 1 90 2.5 1.72 4.74 1.04 Matching 2 90 2.5 1.88 3.90 1.72 Matching ratio 3 90 2.5 2.09 2.88 2.53 Matching ratio 4 90 2.5 2.21 2.28 3.01

[0036] (2) Preparation process:

[0037] The purity of the raw material is more than 99%. The following preparation process is adopted and cast, cooled under natural conditions after casting, and packaged after cooling.

[0038] a. The melting furnace is a melting furnace with mechanical stirring under the protection of nitrogen (SMX-1300, Shanghai Shangqun Electronic Technology Co., Ltd.). Keep warm for 1 hour. After heat preservation, the molten metal was mechanically stirred for 10 minutes at a stirring speed of 60 r / min, cast at room temperature and cooled naturally to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com