Low-odor low-temperature-resistant synthetic rubber leather and preparation method thereof

A synthetic rubber, low-odor technology, applied in the field of artificial leather, can solve the problems of complex production process of polyurethane synthetic leather, inability to eliminate volatile organic compounds, insufficient environmental protection performance, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings.

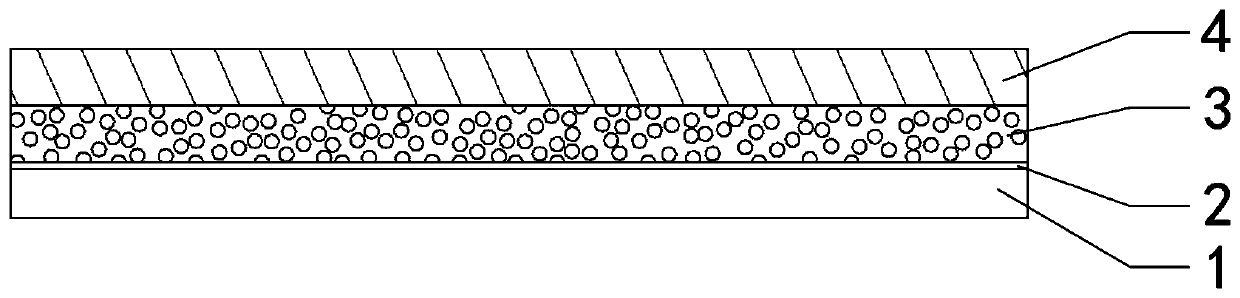

[0026] Such as figure 1 As shown, a low-odor and low-temperature-resistant synthetic rubber leather includes a base fabric layer 1, a hot-melt adhesive layer 2, a synthetic rubber layer 3 and a surface layer 4 laminated in sequence; the hot-melt adhesive layer 2 is EVA hot melt adhesive layer or SIS adhesive layer.

[0027] The hot-melt adhesive layer of the low-odor and low-temperature-resistant synthetic rubber leather provided by the invention has a high bonding strength, which plays a role in improving the bonding firmness of the synthetic rubber leather. Due to the function of performance, it can replace PVC artificial leather in terms of mechanical properties, and the skin feel of the surface layer can replace PU artificial leather and genuine leather. Moreover, synthetic rubber raw materials, hot-melt adhesive films and supporting additives do not co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com