Preparation method of apatite resin sheet for external detector method

A resin sheet and apatite technology, which is applied in the field of apatite resin sheet preparation, can solve problems such as shedding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to make the purpose, technical solutions and advantages of the present invention more clearly understood, the present invention will be further described in detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

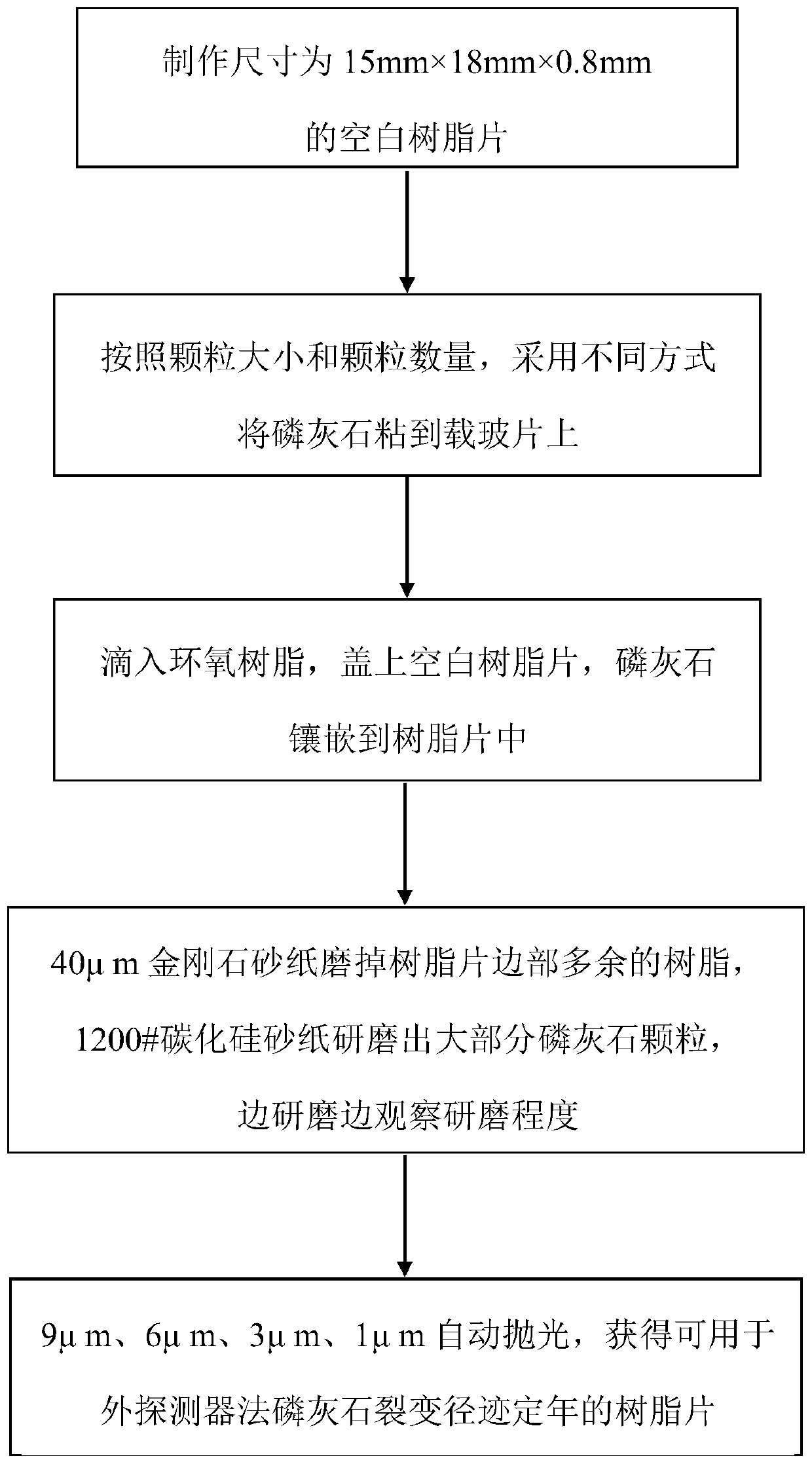

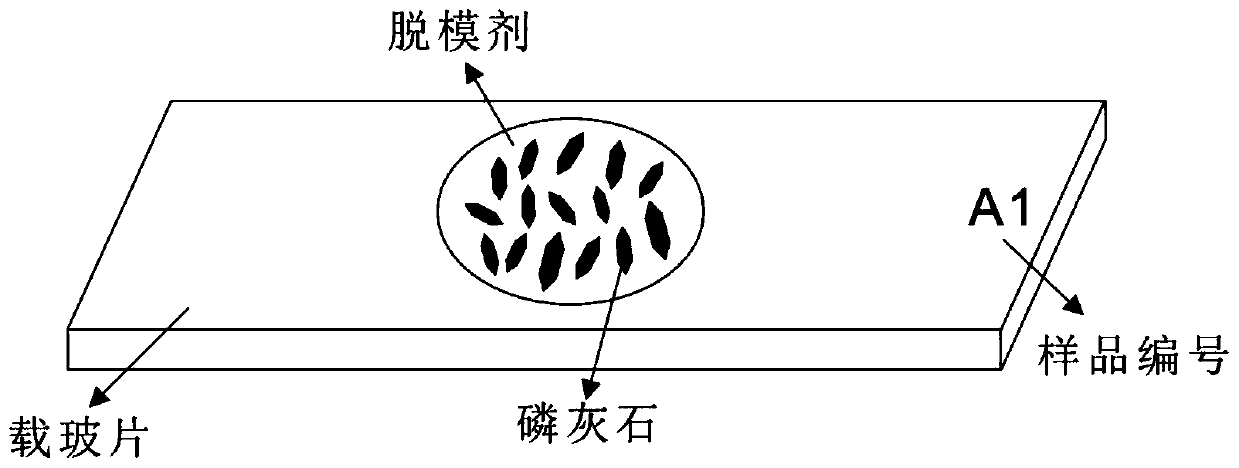

[0034] figure 1 A method for preparing an apatite resin sheet for the external detector method according to an embodiment of the present invention is shown, which includes the following steps:

[0035]Step 1: Weigh 30g of EpoFix epoxy resin into a beaker, add 6.9g of the corresponding curing agent, stir the glass rod clockwise for 5 minutes to make it evenly mixed, put the beaker into a vacuum chamber, and draw a vacuum for 30-40 minutes , and wait until no air bubbles emerge from the resin. Apply mold release agent on the inside of the two glass plates, pour the vacuumed epoxy resin solution into the glass plates, place 0.8mm aluminum sheets on the four corners of the glass plates, and slowly cover it ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com