Laser direct writing micro-nano structure system based on single-wavelength double beams and method

A technology of laser direct writing and micro-nano structure, applied in the field of laser direct writing micro-nano structure system, can solve the problems of different spot sizes, weakening the integration degree of processing system, and restricting system expansion and integration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with drawings and embodiments.

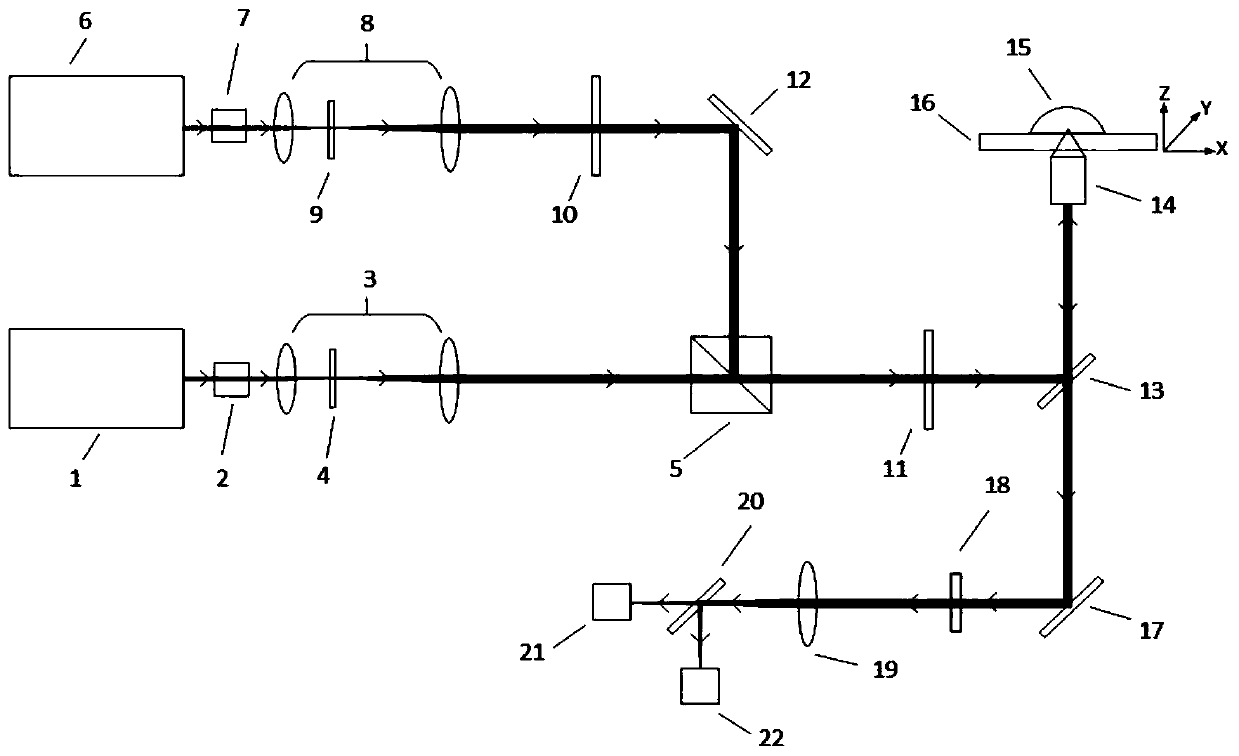

[0037] see figure 1 , one A laser direct writing micro-nano structure system based on single-wavelength and double-beams, comprising: a pulsed laser 1, a first high-speed optical switch 2, a first 4f lens group 3, a first spatial filter aperture 4, a polarizing beam splitter 5, CW laser 6, second high-speed optical switch 7, second 4f lens group 8, second spatial filter aperture 9, spiral phase plate 10, quarter slide 11, first mirror 12, first semi-anti-half Lens 13, objective lens 14, sample to be photoetched 15, displacement platform 16, second mirror 17, optical filter 18, convex lens 19, second half mirror 20, charge-coupled device image sensor 21 and avalanche photodiode 22 The pulse laser 1, the first high-speed optical switch 2 and the first 4f lens group 3 are arranged in sequence, and the first spatial filter aperture 4 is arranged between different lenses ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com