A kind of preparation technology of chloramphenicol adsorbent

A preparation process and adsorbent technology, applied in the field of material modification, can solve problems such as unsatisfactory adsorption effect of chloramphenicol, and achieve the effects of good environmental benefit, low production cost, and improvement of soil conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] A preparation process of chloramphenicol adsorbent, the steps comprising:

[0051] S1: crushing the pine needles after being dried for the first time;

[0052] S2: After the pine needle powder obtained in step S1 is extracted, cleaned for the first time and dried for the second time, soaked in a modifier solution;

[0053] S3: After adjusting the pH of the modifying agent solution in step S2, leave it still;

[0054] S4: The pine needle powder treated in step S3 is washed for the second time and then dried for the third time to obtain the chloramphenicol adsorbent.

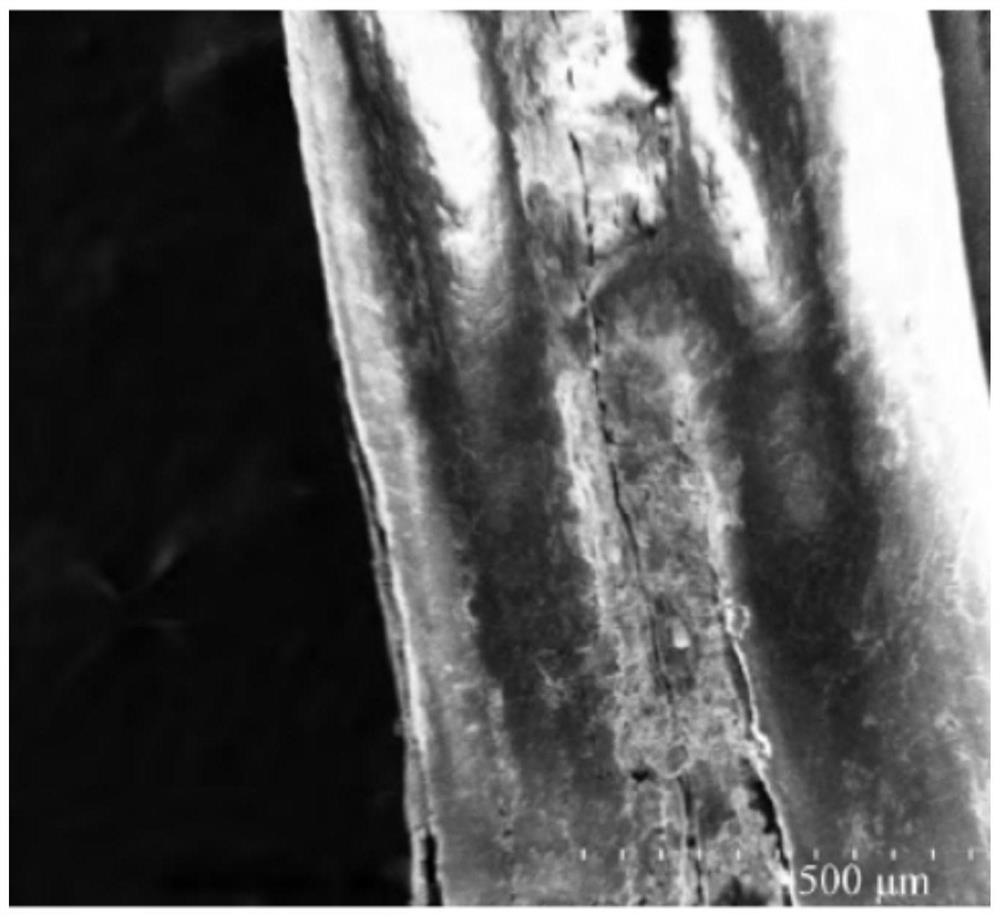

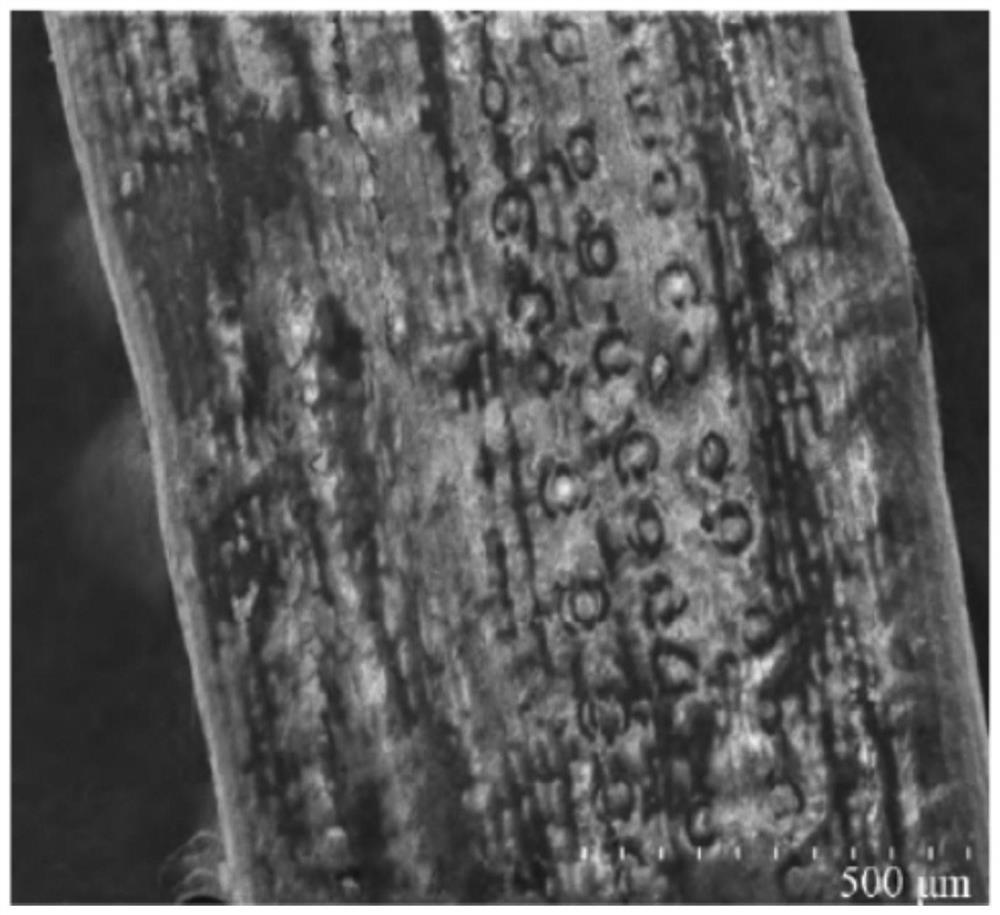

[0055]In the above process, the pine needles are first crushed to obtain a larger surface area, and then the pine needle powder is extracted. The purpose of the extraction treatment is to destroy the outer cuticle structure of the pine needles, so that the pine needle powder is loose and porous, and the fiber structure is exposed. The chloramphenicol adsorbent can be obtained by loading the active agent o...

Embodiment 2

[0067] In this example, a chloramphenicol adsorbent is actually prepared, specifically:

[0068] After washing the pine needles, place them in an oven at 80°C to dry to constant weight, crush and grind the dried pine needles, and collect crushed pine needles below 60 mesh;

[0069] Take 100g crushed pine needles and pass through supercritical CO 2 , 200mL95% NaOH solution to extract the remaining residue after the active ingredients of larch needles were extracted for 10h, washed with distilled water until the supernatant was colorless and transparent, and dried at 80°C to constant weight to obtain modified pine needles;

[0070] Take 20g of modified pine needles and put them into 200mL0.2moL / L phenylenediamine solution, stir for 1h and deposit for 10h, then add sodium hydroxide solution dropwise under stirring conditions, control the pH value at 8-9, and let it stand for 24h. Stir for 5min every 3h;

[0071] After the loading was deposited, the pine needles were washed with...

Embodiment 3

[0073] In this example, a chloramphenicol adsorbent is actually prepared, specifically:

[0074] After washing the pine needles, place them in an oven at 80°C to dry to constant weight, crush and grind the dried pine needles, and collect crushed pine needles below 60 mesh;

[0075] Take 100g crushed pine needles and pass through supercritical CO 2 , 200mL95% NaOH solution to extract the remaining residue after the active ingredients of larch needles were extracted for 12h, washed with distilled water until the supernatant was colorless and transparent, and dried at 80°C to constant weight to obtain modified pine needles;

[0076] Take 20g of modified pine needles and put them into 200mL0.4moL / L phenylenediamine solution, stir for 1h and deposit for 12h, then add sodium hydroxide solution dropwise under stirring conditions, control the pH value at 8-9, and let it stand for 24h. Stir for 5min every 3h;

[0077] After the loading was deposited, the pine needles were washed with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com