Calcium-removing method and calcium-removing device for softening desulfurization wastewater

A technology for desulfurization wastewater and feeding devices, which is applied in water softening, chemical instruments and methods, and gaseous effluent wastewater treatment, etc. It can solve the problems of increased acid addition, large sodium carbonate dosage, and high dosage costs, etc. problem, to achieve the effect of improving removal efficiency and reducing dosing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The inventor of the present application found in experiments: under the condition of adding the same sodium carbonate dosing ratio, compared with not adding a decalcification accelerator before adding sodium carbonate, adding decalcification before adding sodium carbonate The calcium ion concentration in the desulfurization wastewater decreased significantly after the accelerator was added with the same amount of sodium carbonate, as shown in Table 2.

[0036] Table 2 Adding Calcium Removal Hard Accelerator to the Effect of Calcium Removal

[0037]

Embodiment 2

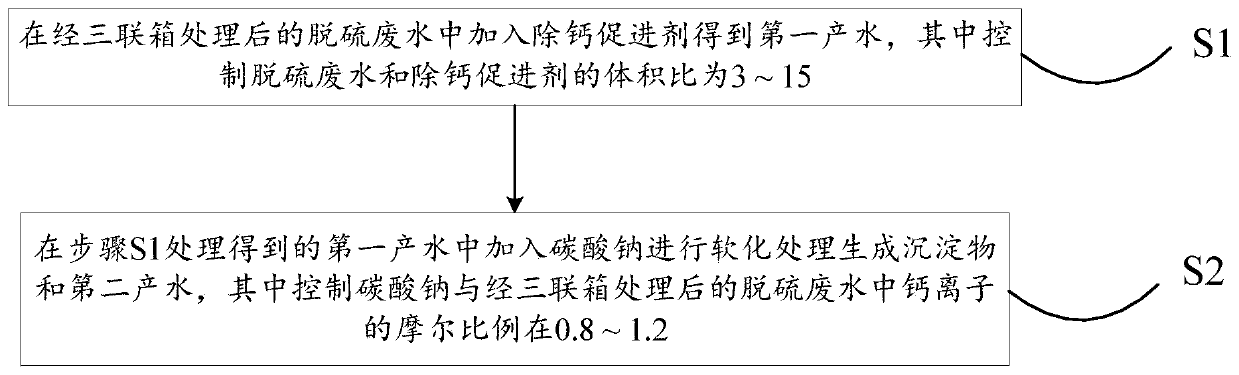

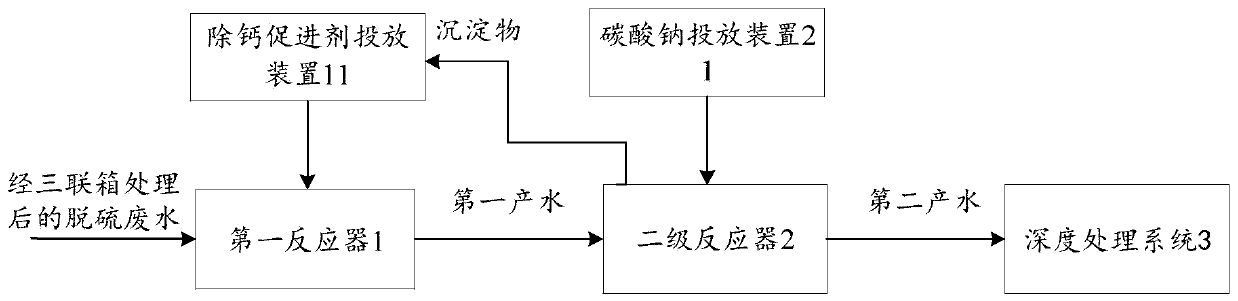

[0039] On the basis of the above steps S1 and S2, the following test S1 was implemented: adding a decalcification accelerator to the desulfurization wastewater treated by the triple box to obtain the first produced water, wherein the volume ratio of the desulfurization wastewater and the decalcification accelerator was controlled to be 3 to 15. S2: Add sodium carbonate to the first product water obtained in step S1 for softening treatment to generate sediment and second product water, wherein the molar ratio of sodium carbonate to calcium ions in the desulfurization wastewater treated by the triple box is 1.1, and The results shown in Table 3 are obtained:

[0040] Table 3 Effect of adding calcium removal accelerator ratio on wastewater calcium removal

[0041]

[0042] It can be seen from Table 3 that adding an appropriate amount of calcium removal accelerator can significantly reduce the calcium ion in the desulfurization wastewater after the reaction in step S2, and the...

Embodiment 3

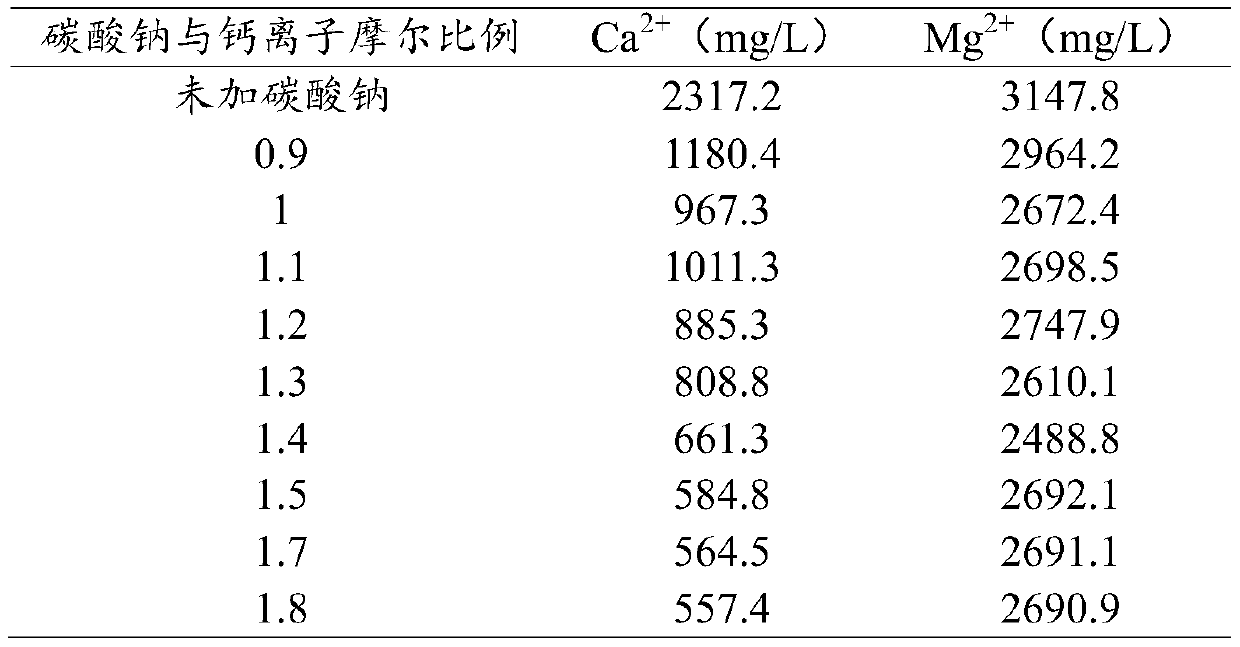

[0044] On the basis of the above steps S1 and S2, the following test S1 was implemented: adding a decalcification accelerator to the desulfurization wastewater treated by the triple box to obtain the first produced water, wherein the volume ratio of the desulfurization wastewater and the decalcification accelerator was controlled to be 3. S2: Sodium carbonate is added to the first product water obtained in step S1 for softening treatment to generate sediment and second product water, wherein the molar ratio of sodium carbonate to calcium ions in the desulfurization wastewater treated by the triple box is controlled to be 0.8 to 1.2 , and get the results shown in Table 4:

[0045] Table 4 Effects of different dosages of sodium carbonate on decalcification of wastewater

[0046]

[0047]

[0048] It can be seen from Table 4 that after adding the calcium removal accelerator in step S1, sodium carbonate with a different ratio of calcium ions in the desulfurization wastewate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com