Microgel reinforced dual-network hydrogel and preparation method thereof

A hydrogel and double-network technology, applied in the field of microgel-enhanced double-network hydrogel and its preparation, can solve problems such as complex process, difficulty in controlling monomer molar ratio, and gap in mechanical properties, and achieve compression-swelling time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

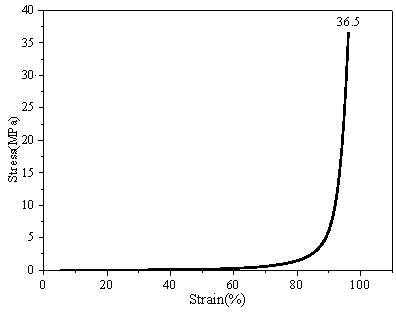

Embodiment 1

[0015] Dissolve 2.07g of 2-acrylamide-2-methylpropanesulfonic acid, 0.062g of N,N-methylenebisacrylamide, 0.027g of potassium persulfate and 0.029g of acrylamide into 10mL of water, and react at a temperature of 60°C 3h, take out the formed first network hydrogel, dry it, and break it into powder. Then 15g of acrylamide, 0.05g of potassium persulfate and 0.017g of N,N-methylenebisacrylamide were dissolved in 100mL of water, and the hydrogel powder obtained by grinding was mixed with the prepared monomer solution at a ratio of 1:45. The reaction was carried out at 60°C for 3 h to prepare a high-strength double network hydrogel.

Embodiment 2

[0017] Dissolve 2.07g of 2-acrylamide-2-methylpropanesulfonic acid, 0.062g of N,N-methylenebisacrylamide, 0.027g of potassium persulfate and 0.029g of acrylamide into 10mL of water, and react at a temperature of 60°C 3h, take out the formed first network hydrogel, dry it, and break it into powder. Then 15g of acrylamide, 0.05g of potassium persulfate and 0.017g of N,N-methylenebisacrylamide were dissolved in 100mL of water, and the hydrogel powder obtained by grinding was mixed with the prepared monomer solution at a ratio of 1:41. The reaction was carried out at 60°C for 3 h to prepare a high-strength double network hydrogel.

Embodiment 3

[0019] Dissolve 2.07g of 2-acrylamide-2-methylpropanesulfonic acid, 0.062g of N,N-methylenebisacrylamide, 0.027g of potassium persulfate and 0.029g of acrylamide into 10mL of water, and react at a temperature of 60°C 3h, take out the formed first network hydrogel, dry it, and break it into powder. Then 15g of acrylamide, 0.05g of potassium persulfate and 0.017g of N,N-methylenebisacrylamide were dissolved in 100mL of water, and the hydrogel powder obtained by grinding was mixed with the prepared monomer solution at a ratio of 1:43. The reaction was carried out at 60°C for 3 h to prepare a high-strength double network hydrogel.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com