A method for swelling modified and strengthened pyrolysis of waste tires to produce oil and carbon black

A waste tire and pyrolysis technology, applied in the field of waste tire resource utilization, can solve the problems of poor product quality and selectivity, long swelling time, easy coking, etc., to save swelling time, improve pyrolysis performance, and reduce energy consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

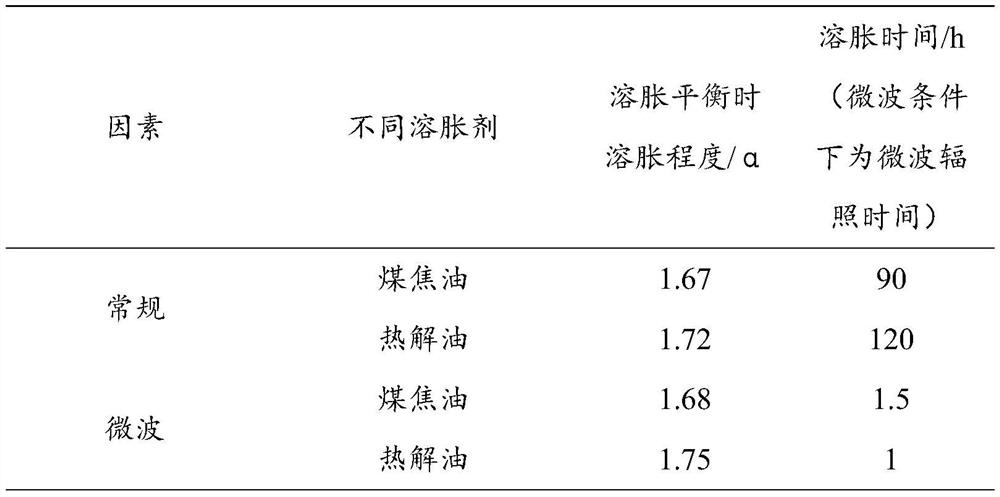

[0051] A method for swelling waste tires, the steps are as follows:

[0052] 1) Process the waste tire blocks into the same size (1×1cm small pieces), wash them, and place them in closed storage tanks containing different swelling agents (heavy components of pyrolysis oil (>240°C fraction), coal tar ) in the beaker, the swelling agent has not crossed the surface of the tire block, and stirred evenly with a glass rod;

[0053] 2) Put the beaker in step 1) in a water bath, add the rotor to make full contact, set the temperature of the water bath to 40°C, take out the tire block every 1 hour, wash and weigh it, and record the data for comparison with the swelling under microwave conditions .

[0054] The swelling degree is calculated by the ratio of the mass difference before and after swelling to the mass before swelling, which reflects the swelling effect of different tire blocks.

Embodiment 2

[0056] A method for microwave-enhanced swelling of waste tires, the steps are as follows:

[0057] 1) Process the waste tire blocks into the same size (1×1cm small pieces), wash them, and place them in closed storage tanks containing different swelling agents (heavy components of pyrolysis oil (>240°C fraction), coal tar ) in the beaker, the swelling agent has not crossed the surface of the tire block, and stirred evenly with a glass rod.

[0058] 2) Place the beaker in step 1) in the microwave field, and set the microwave power to 900W. In order to prevent the volatilization of the solvent, first microwave for 20s, control the temperature below 40°C, stop the microwave heating, and when the temperature is lower than 30°C, microwave Heat for 10s, repeat the experiment until the swelling is saturated, and always control the temperature within the range of 0-40°C. In the experiment, the tire blocks were taken out every 3 minutes according to the microwave irradiation time, wash...

Embodiment 3

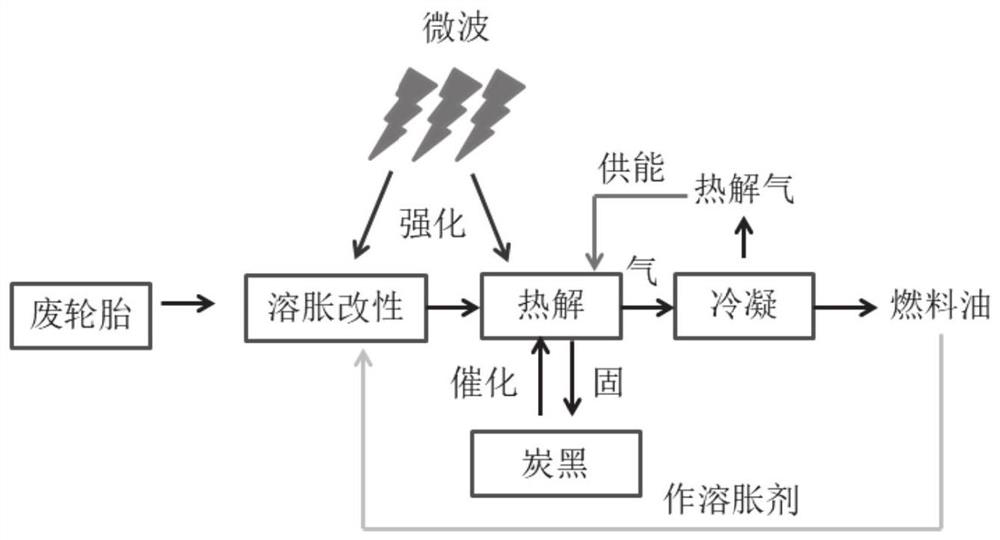

[0065] A method for swelling modified and strengthened pyrolysis of waste tires to produce oil and carbon black, such as figure 1 As shown, the steps are as follows:

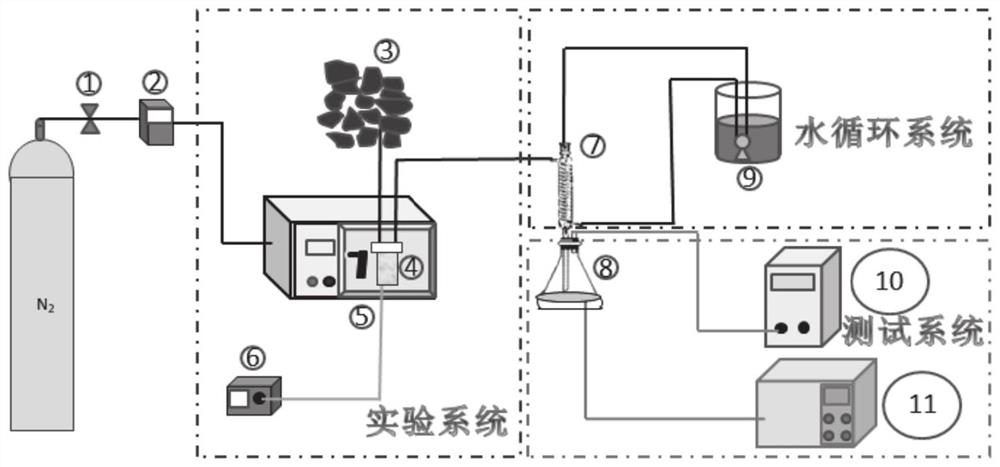

[0066] 1) Weigh 30 g of waste tire blocks before and after swelling, and place figure 2 The shown microwave pyrolysis experimental system includes: a pressure reducing valve 1, a mass flow meter 2, a material 3, a quartz reactor 4, a microwave oven 5, a thermometer 6, a condenser tube 7, a pyrolysis oil collection device 8, a circulation water pump9. The chamber of the quartz reactor is a cylinder with a height of 143mm and a wall thickness of 2mm. There is a porous plate inside, 20mm away from the bottom of the reactor, an air inlet is set in the middle, an air outlet is set at the top of the reactor, and the rest is sealed. The swelling of waste tires uses microwaves to enhance the swelling of waste tires by the heavy components of pyrolysis oil (>240°C fraction).

[0067] 2) Before the start of the experi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com