Emulsifier composition for forming oil-water emulsion

A technology of a composition and an emulsifier, which is applied in the directions of drilling compositions, chemical instruments and methods, instruments, etc., can solve the problems of high cost, environmental pollution, unfavorable logging operations, etc., and achieves low cost, simple and fast preparation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

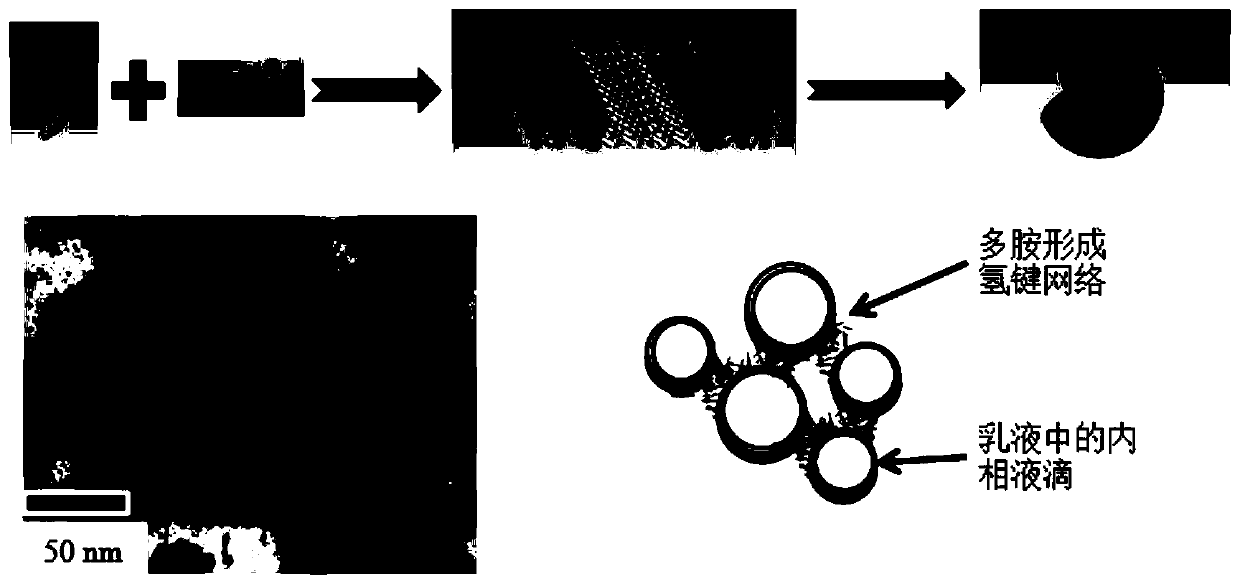

[0070] Example 1 Oleic acid-diethylenetriamine (1:4) as oil-water emulsifier

[0071] First, oleic acid, diethylenetriamine and deionized water are prepared into a concentrated solution according to the mass ratio of 1:4:5, that is, an aqueous solution (i) with an emulsifier content of 50 wt%, and then diluted into a 3 wt% aqueous solution (ii), At the same time, prepare oil-water mixtures (white oil-deionized water) according to different oil-water ratios, then add the aqueous solution (ii) to the oil-water mixture according to the mass ratio of oil-water mixture:water solution (ii)=9:1, and stir at a speed of 250rpm 15 minutes, standing for 15 minutes to obtain an emulsion, and then measure the conductivity of the emulsion according to the provisions of the HG / T3506 standard.

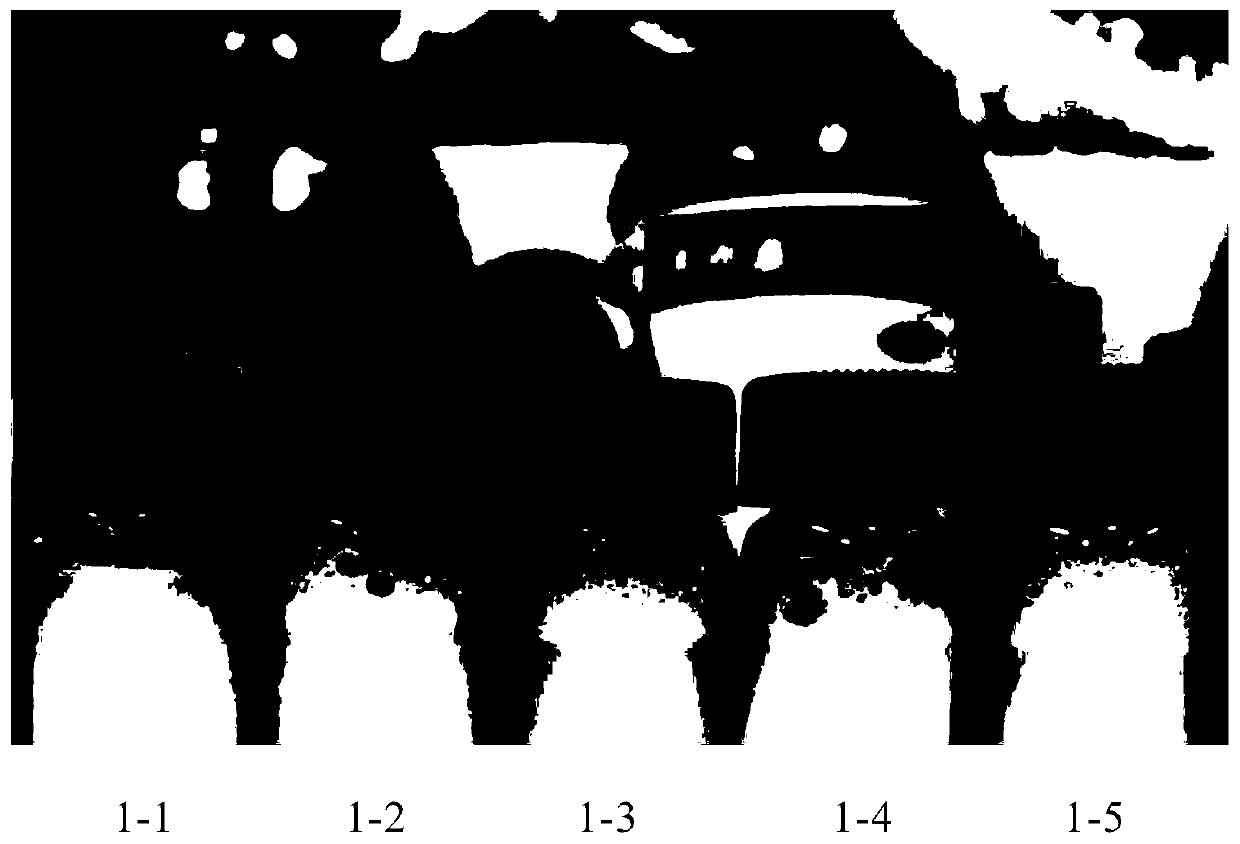

[0072] Emulsion type is determined by conductivity. When the measured conductivity is greater than 18mS / cm, it is judged that the emulsion is an oil-in-water emulsion (W / O), otherwise, if the measure...

Embodiment 2

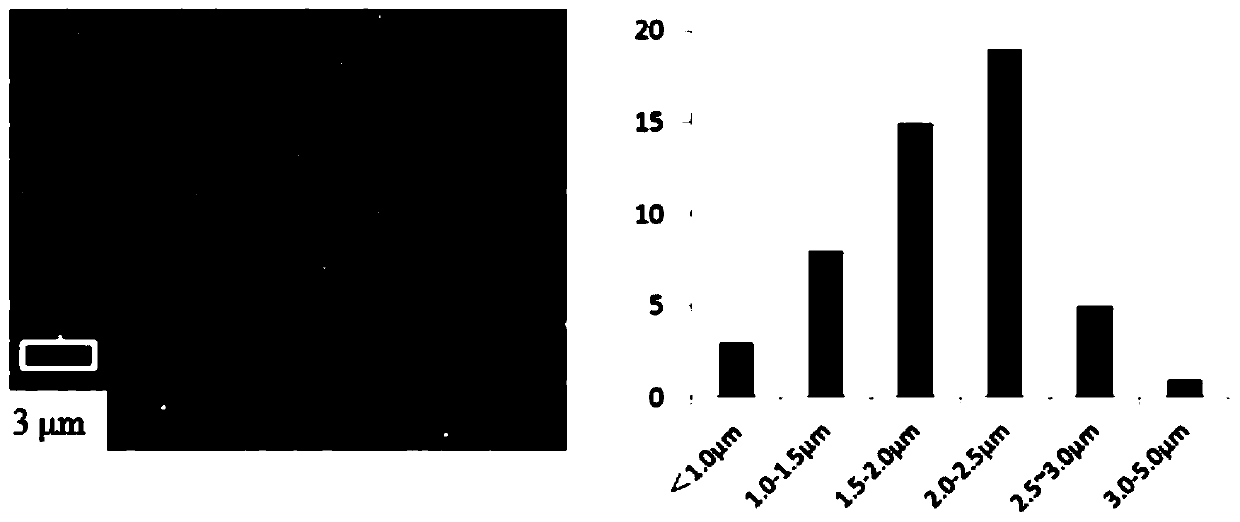

[0078] The influence of embodiment 2 emulsifier composition on emulsion conductivity and viscosity

[0079] Prepare the emulsion according to the method of Example 1, the difference is that the oil-water ratio of the oil-water mixture is 9.5:0.5; and the molar ratio of diethylenetriamine / (diethylenetriamine+oleic acid) is 0, 0.1, 0.2 respectively , 0.3, 0.4 and 0.5 (ie, mole percent 0%, 10%, 20%, 30%, 40% and 50%). The conductivity and viscosity of the obtained emulsion were measured, and the results were as follows: Figure 4 shown.

[0080] Depend on Figure 4 The results show that as the ratio of polyamines and organic acids in the emulsifier composition increases gradually, the conductivity of the resulting emulsion increases and the viscosity decreases. In practical applications, the appropriate expected conductivity and viscosity can be selected in consideration of the actual situation, so as to determine the composition of the emulsifier composition.

Embodiment 3

[0081] The influence of embodiment 3 different oil-water ratios on emulsion conductivity and emulsion type

[0082] Prepare the emulsion according to the method of Example 1, the difference is that the water-oil volume ratio of the oil-water mixture is 1:1, 2:1, 5:1, 10:1, 20:1, 50:1 and 100:1 respectively and, the mol ratio of diethylenetriamine and oleic acid is 1:1. The electrical conductivity of gained emulsion is measured, and judge the type of emulsion obtained, the result is shown in table 2.

[0083] Table 2 Emulsifier

[0084] Water: oil (volume ratio) Conductivity lotion type 1:1 0.008 water in oil 2:1 0.018 water in oil 5:1 0.035 water in oil 10:1 0.052 water in oil 20:1 0.027 water in oil 50:1 0.043 water in oil 100:1 0.066 water in oil

[0085] As can be seen from the results in Table 2, for the oil-water mixtures of different oil-water ratios, the water-in-oil emulsion with excellent performance...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com