Floodplain area bearing platform reinforced concrete bottom sealing structure and construction method thereof

A reinforced concrete and construction method technology, applied in the direction of basic structure engineering, construction, etc., can solve the problems of increased construction personnel investment, high construction cost, unbalanced internal and external water pressure, etc., and achieves the reduction of the thickness of the back cover concrete, significant economic benefits, The effect of speeding up the construction progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

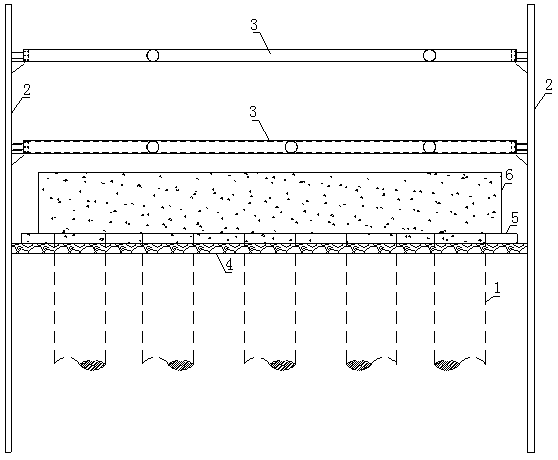

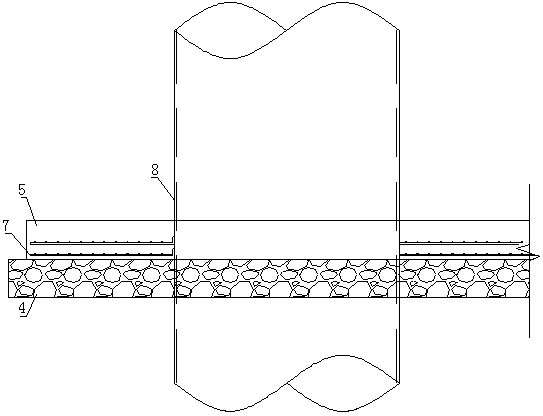

[0052] The bottom sealing structure of the cap platform steel cofferdam foundation pit in the floodplain area provided by the present invention, such as figure 1 , figure 2 shown, including:

[0053] Steel sheet pile cofferdam 2;

[0054] The bridge pile foundation 1 is provided with several pieces, and the several bridge pile foundations 1 are arranged at the bottom of the steel sheet pile cofferdam 2 at intervals;

[0055] The inner support 3 is arranged on the upper part of the steel sheet pile cofferdam 2 in upper and lower layers, and the end of the inner support 3 is fixed on the inner wall of the steel sheet pile cofferdam 2;

[0056] Slab stone 4 is laid on the base of the steel sheet pile cofferdam 2;

[0057] Back-sealing concrete 5, said back-sealing concrete 5 is located on the top surface of said flake 4;

[0058] A platform 6, the platform 6 is arranged on the top surface of the concrete 5 for the back cover.

[0059] This embodiment further provides a cons...

Embodiment approach 2

[0067] Embodiment 2 of the present invention relates to a bottom sealing structure of a steel cofferdam foundation pit in a floodplain area, such as figure 1 , figure 2 As shown, it includes: steel sheet pile cofferdam 2, internal support 3, sheet stone 4, back cover concrete 5 and cap 6; the bottom of the steel sheet pile cofferdam 2 is provided with several bridge pile foundations 1 at intervals; the steel sheet pile cofferdam 2 is provided with an inner support 3, the inner support 3 is divided into upper and lower layers, and the end of the inner support 3 is fixed on the inner wall of the steel sheet pile cofferdam 2; the flake 4 is laid on the steel sheet pile cofferdam 2 on the base; the back-sealing concrete 5 is set on the top surface of the flake 4; the platform 6 is set on the top surface of the back-sealing concrete 5 . The reinforced concrete back cover of the cap can reduce the depth of the steel sheet pile cofferdam and reduce the difficulty of steel sheet pil...

Embodiment approach 3

[0073] Embodiment 3 of the present invention relates to a construction method for a reinforced concrete bottom-sealing structure of a cap platform in a floodplain area, including the following steps:

[0074] S1 Clean the foundation in the steel sheet pile cofferdam 2, dig out the silt in the steel sheet pile cofferdam 2, and further, use the long-arm excavator and manual cooperation to clean the silt to the bottom concrete below the bottom level;

[0075] S2 After the foundation clearing of the steel sheet pile cofferdam 2 is completed, base treatment is carried out so that the base of the steel sheet pile cofferdam 2 has a certain bearing capacity; because the cap is located in the floodplain area, the water head difference between the inside and outside of the steel cofferdam is small, and even the local water level is below the ground Below, the ground where the back cover concrete is located is an impermeable layer. Therefore, the back cover concrete mainly bears the load...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com