Grayscale photomask and manufacturing method of display substrate

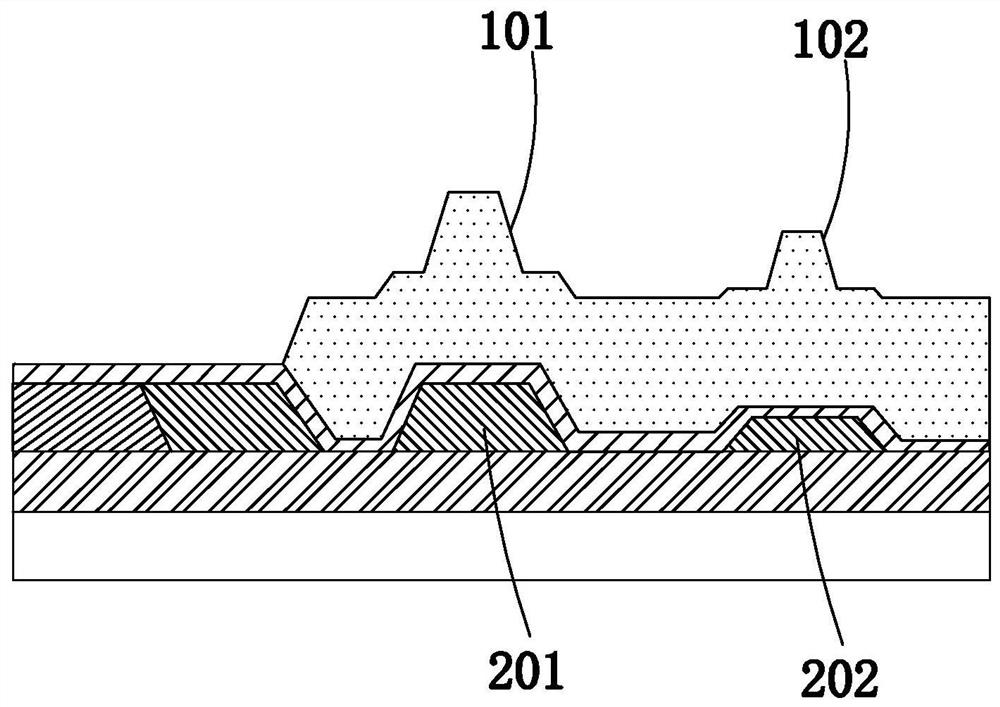

A technology of grayscale mask and manufacturing method, which is applied in the photoplate making process of the pattern surface, the original for photomechanical processing, optics, etc., and can solve the problem of affecting product quality, small exposure, and the second film liner 202 To prevent peeling and other problems, to achieve the effect of preventing peeling and improving the stability of film formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In order to further illustrate the technical means adopted by the present invention and its effects, the following describes in detail in conjunction with preferred embodiments of the present invention and accompanying drawings.

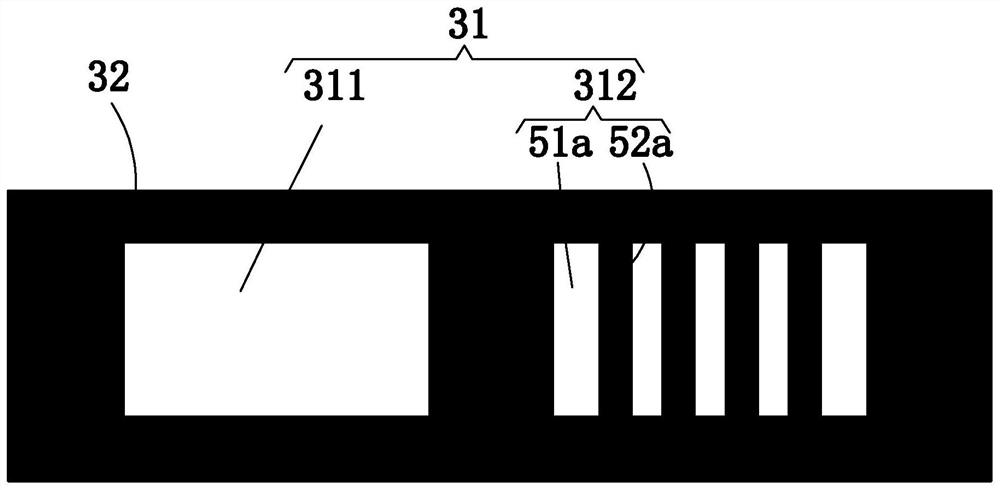

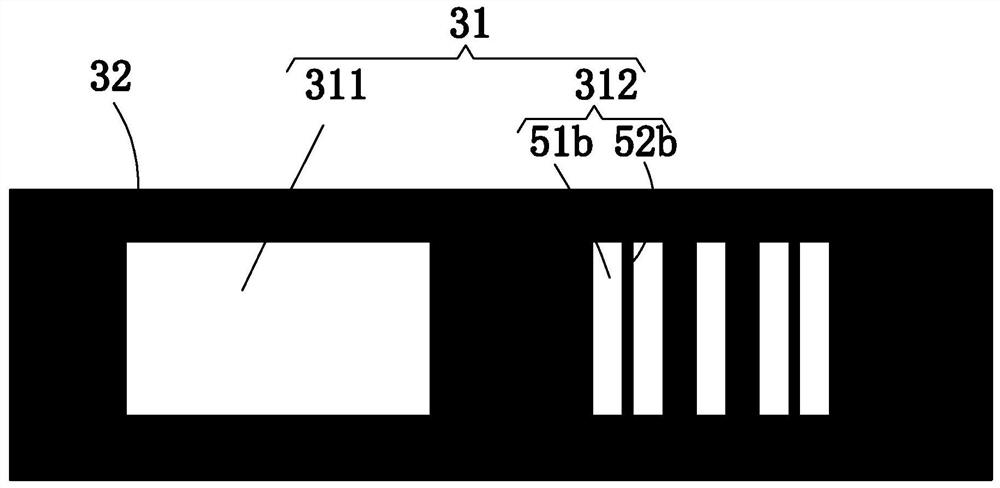

[0043] see Figure 2 to Figure 5 . The present invention provides a gray scale photomask, comprising a light-transmitting area 31 and a light-shielding area 32 surrounding the light-transmitting area 31 , and the light-transmitting area 31 includes the first film liner 41 arranged in sequence for forming the first A light-transmitting region 311 and a second light-transmitting region 312 for forming the second film liner 42, the first light-transmitting region 311 is completely light-transmitting, and the second light-transmitting region 312 is partially light-transmitting;

[0044] The thickness of the first film liner 41 is greater than that of the second film liner 42, and the second light-transmitting region 312 has undergone anti-peeling ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com