Modified asphalt mixing storage device and method

A technology of modified asphalt and storage devices, which is applied in the direction of mixers with rotating stirring devices, mixing methods, mixer accessories, etc., which can solve the problems of toxic gas environmental pollution, etc., and achieve the effect of reducing residues and increasing the output speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

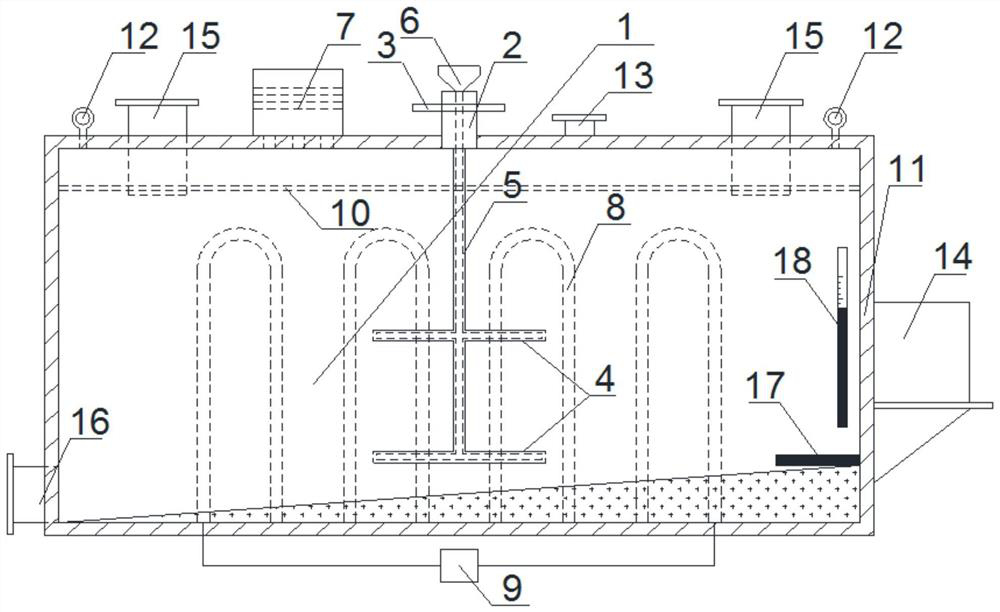

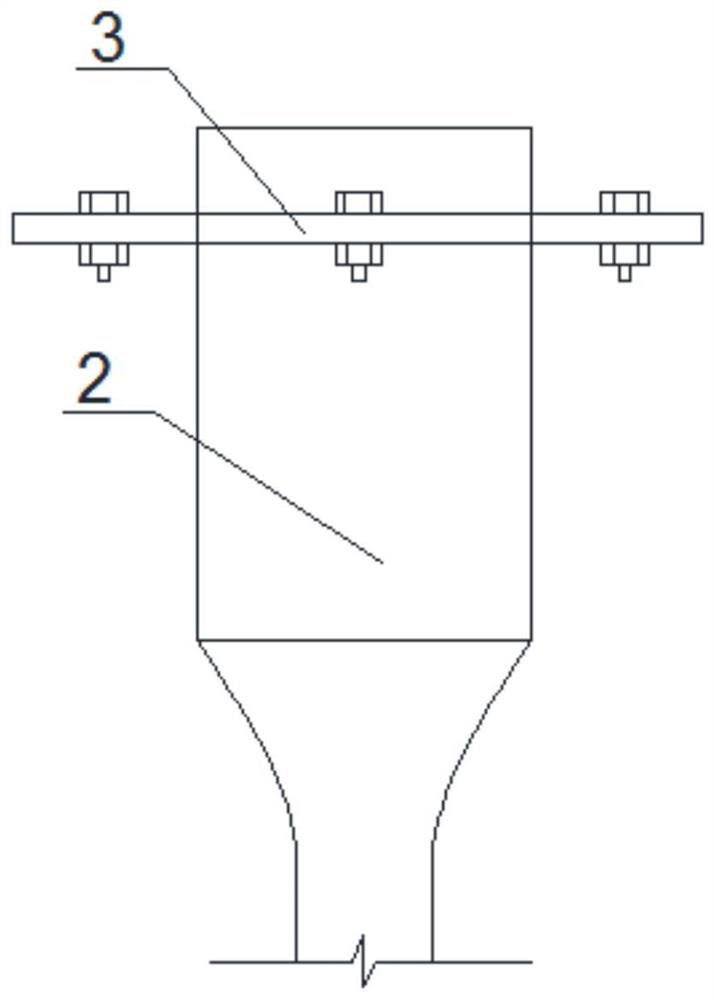

[0034] Please refer to figure 1 with image 3 , a modified asphalt mixing and storage mechanism, including a tank body 1, a motor 2, a motor cover plate 3, a double-layer stirring blade 4, a stirring shaft 5, a pumping mechanism 6, a purification box 7, a spiral heating tube 8, a temperature control Mechanism 9, shaker 10; the stirring shaft 5 passes through the outer wall of the tank body 1 and enters the interior of the tank body 1, the double-layer stirring blade 4 is connected to the end of the stirring shaft 5, the spiral heating tube 8 is installed on the curved surface of the tank body, and the spiral heating tube 8 can be used as a heating mechanism to heat the asphalt in the tank. The outermost side of the curved surface of the tank body 1 is covered with an insulating layer. The temperature control mechanism 9 is connected to the spiral heating pipe 8, and the temperature control mechanism 9 is installed inside the tank body; the stirring shaft 5 and The inside of t...

Embodiment 2

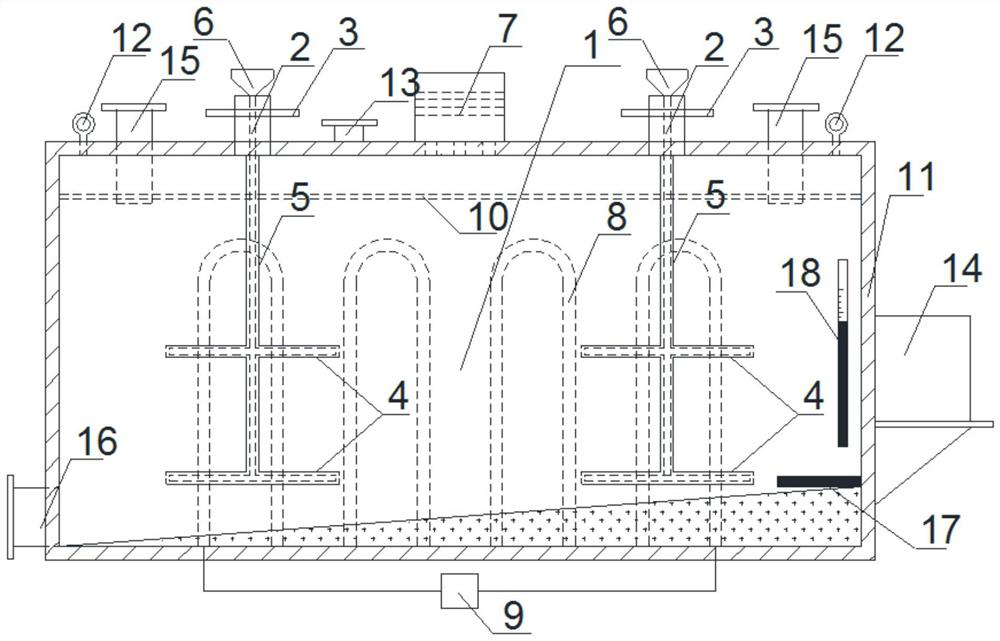

[0052] The difference between embodiment 2 and embodiment 1 is that in embodiment 2, the length of the tank body is greater than 7m and less than 12m, and the two motors 2 are respectively fixed at 1 / 4 of the inward direction on both sides of the upper curved surface of the tank body 1;

[0053] Similarly, two double-layer stirring blades 4 and stirring shafts 5 are also provided with two, and the two stirring shafts 5 enter the tank body at 1 / 4 of the inward direction on both sides of the upper curved surface of the tank body 1 respectively. The leaves 4 are respectively connected with two stirring shafts 5 .

[0054] Similarly, in this embodiment, the purification box 7 is installed at 1 / 2 of the length direction of the upper curved surface of the tank body 1 .

Embodiment 3

[0056] Embodiment 3 discloses a modified asphalt agitation storage method, using the modified asphalt agitation storage device as described in embodiment 1 or embodiment 2, comprising the following steps:

[0057] 1) After the hoisting of the mixing tank is completed, open the feed ports 15 on both sides above the modified asphalt mixing storage device, store the asphalt in the storage tank, and observe the amount of asphalt inside the tank in real time through the high-level observation tube 18 , now open the spiral heating tube 8 in the electric control box 14 and the stirring switch of the motor 2, and add the asphalt modifier, then slowly close the feed port 15;

[0058] 2) Turn on the 6 switches of the shaking screen or the pumping mechanism in the electric control box to add the external admixture. Due to the difference in the form and state of the external admixture, the method of adding the external admixture is slightly different in this embodiment, specifically , whe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com