A composite solid electrolyte membrane and its preparation method, solid-state battery

A solid-state electrolyte membrane, solid-state electrolyte technology, applied in electrolytes, secondary batteries, circuits, etc., can solve the problem of not taking into account high voltage resistance, high ionic conductivity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

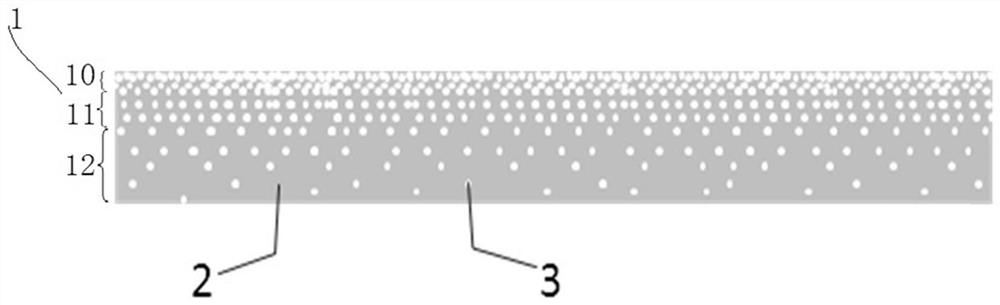

[0031] The composite solid electrolyte membrane of this embodiment, the structure diagram is as follows figure 1 As shown, the composite solid electrolyte membrane 1 includes a positive electrode side electrolyte layer 10, an intermediate electrolyte layer 11 and a negative electrode side electrolyte layer 12, and the positive electrode side electrolyte layer 10, the intermediate electrolyte layer 11 and the negative electrode side electrolyte layer 12 are all composed of polymer electrolytes 2 and Inorganic solid electrolyte 3 composition.

[0032] The thicknesses of the positive electrode side electrolyte layer 10, the intermediate electrolyte layer 11, and the negative electrode side electrolyte layer 12 are 5 μm, 10 μm, and 5 μm respectively. In the above three layers, the mass content of the inorganic solid electrolyte is 95%, 50%, and 5%, respectively. The mass contents of the electrolytes are 5%, 50%, and 95%, respectively.

[0033] The inorganic solid electrolyte is gar...

Embodiment 2

[0039] The composite solid electrolyte membrane of this embodiment contains two electrolyte layers, namely a positive electrode side electrolyte layer and a negative electrode side electrolyte layer, and both the positive electrode side electrolyte layer and the negative electrode side electrolyte layer are composed of polymer electrolytes and inorganic solid electrolytes.

[0040] Both the electrolyte layer on the positive electrode side and the electrolyte layer on the negative electrode side have a thickness of 10 μm. In the electrolyte layer on the positive electrode side, the content of inorganic solid electrolyte is 95%, and the content of polymer electrolyte is 5%. In the electrolyte layer on the negative electrode side, the content of inorganic solid electrolyte is The content of polymer electrolyte is 5%, and the content of polymer electrolyte is 95%. The material composition of the inorganic solid electrolyte and the polymer electrolyte is the same as in Example 1.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com