Carrier filter and its application in sewage treatment

A filter and carrier technology, applied in the carrier filter and its application in sewage treatment, can solve the problems of high operation and maintenance and manufacturing costs, high difficulty in backwashing, high SS of effluent, achieve stable operation and reduce backwashing Difficulty, effect of reducing floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

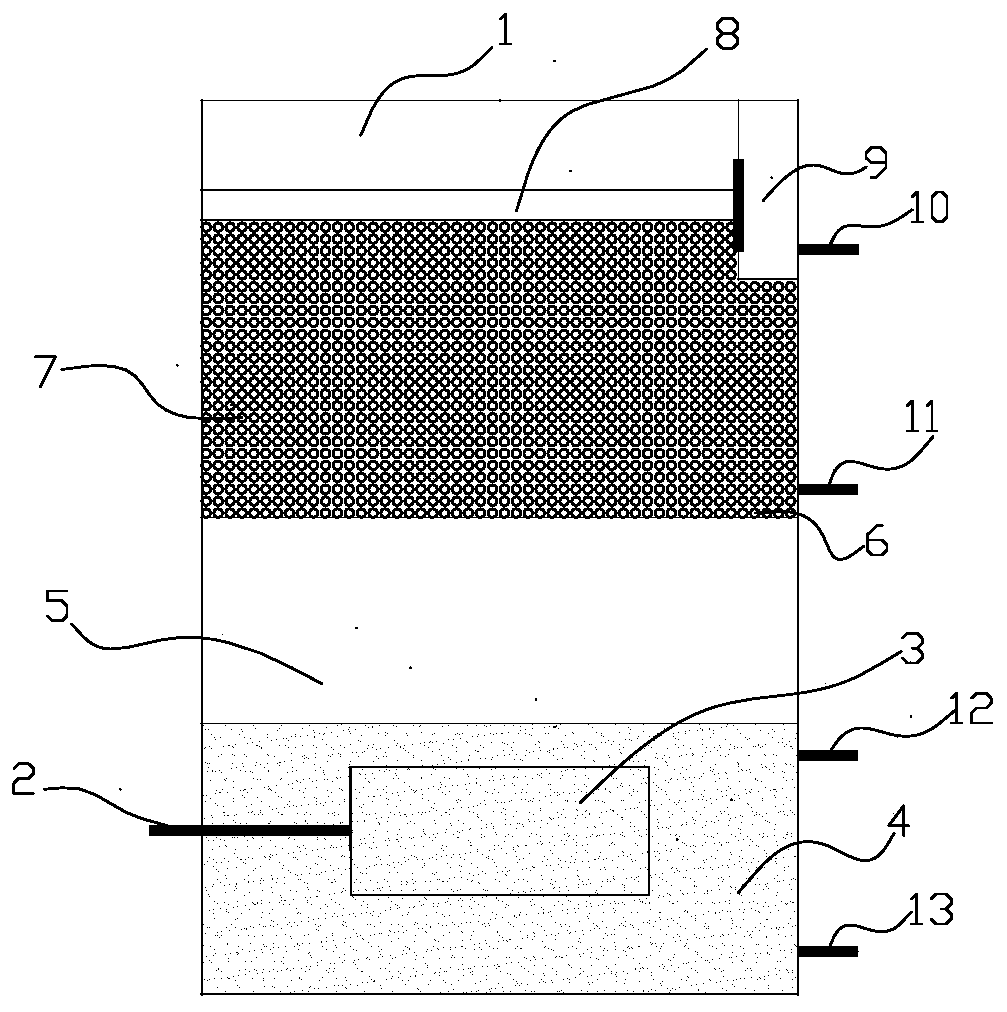

[0031] Such as figure 1 As shown, a carrier filter includes a housing 1, a suspended carrier bed 7 arranged inside the housing 1, a sludge buffer zone 5 and a sludge layer 4; the inside of the sludge layer 4 is provided with a water distribution system 3. The above-mentioned water distribution system 3 is connected to one end of the water inlet pipe 2, and the other end of the water inlet pipe 2 extends out of the shell 1; the above-mentioned sludge buffer zone 5 is interposed between the sludge layer 4 and the suspension carrier bed 7, The suspended carrier bed 7 and the sludge buffer zone 5 are separated by a support screen 6, and an outlet water interception screen 8 is also arranged above the above-mentioned suspension carrier bed 7, and the above-mentioned outlet interception screen 8 is also connected with the sump 9. The water tank 9 is located above the suspended carrier bed 7 and communicates with the shell 1; the shell 1 is also provided with an outlet pipe 10, a bac...

Embodiment 2

[0050] The difference with embodiment 1 is:

[0051] The above-mentioned water distribution system 3 selects a flat hole water distributor;

[0052] The height of the above-mentioned suspended carrier bed 7 is 0.4m, the height of the above-mentioned sludge buffer zone 5 is 0.3m, and the height of the above-mentioned sludge layer 4 is 0.5m;

[0053] The suspension carrier bed 7 is filled with a suspension carrier, the shape of the suspension carrier is spherical, the material of the suspension carrier is PP, and the diameter is 10mm;

[0054] Above-mentioned supporting screen cloth 6 is flat screen cloth, and the opening size of supporting screen cloth 6 is 8mm;

[0055] The water outlet intercepting screen 8 is a flat screen, and the opening size of the outlet water intercepting screen 8 is 8mm.

Embodiment 3

[0057] The difference with embodiment 1 is:

[0058] The water distribution system adopts perforated pipe water distributor;

[0059] The height of the above-mentioned suspended carrier bed is 1.5m, the height of the above-mentioned sludge buffer zone is 0.7m, and the height of the above-mentioned sludge layer is 1.2m;

[0060] The suspension carrier bed is filled with suspension carriers, the shape of the suspension carrier is spherical, the material of the suspension carrier is PP, and the diameter is 38mm;

[0061] The above-mentioned support screen is a flat screen, and the opening size of the support screen is 20mm;

[0062] The above-mentioned water outlet intercepting screen is a drum screen, and the opening size of the water outlet intercepting screen is 20 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com