Intelligent garbage classification method based on machine learning and automatic garbage sorting device

A garbage sorting and automatic sorting technology, which is applied in the direction of garbage cans, garbage collection, waste collection and transfer, etc., can solve the problems of increasing the difficulty and workload of sorting, glass or other garbage personnel injury, and increasing the number of garbage bins, etc. , to achieve the effects of saving labor costs and time costs, saving deployment costs, and fast calculation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

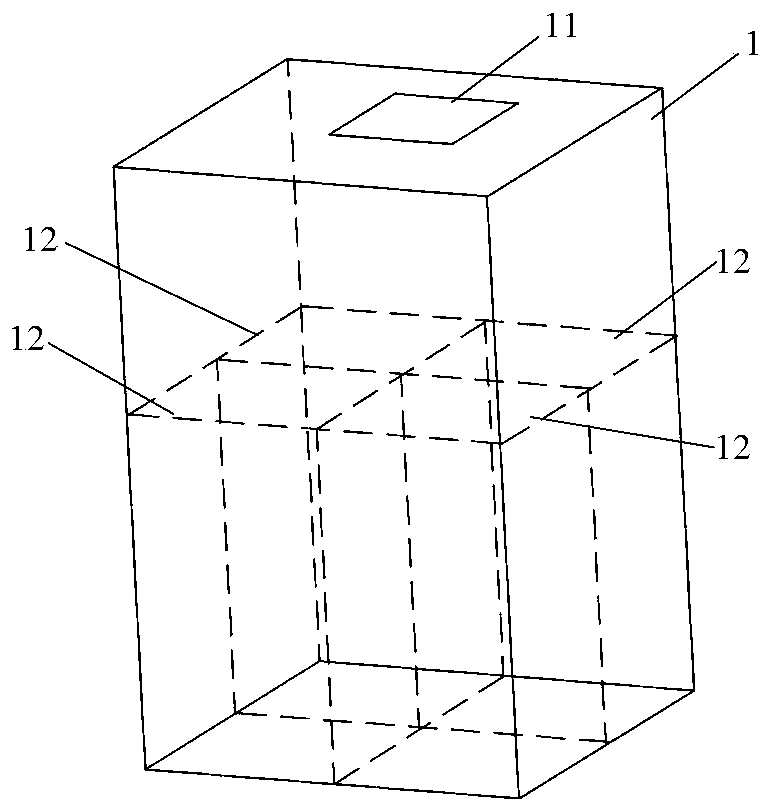

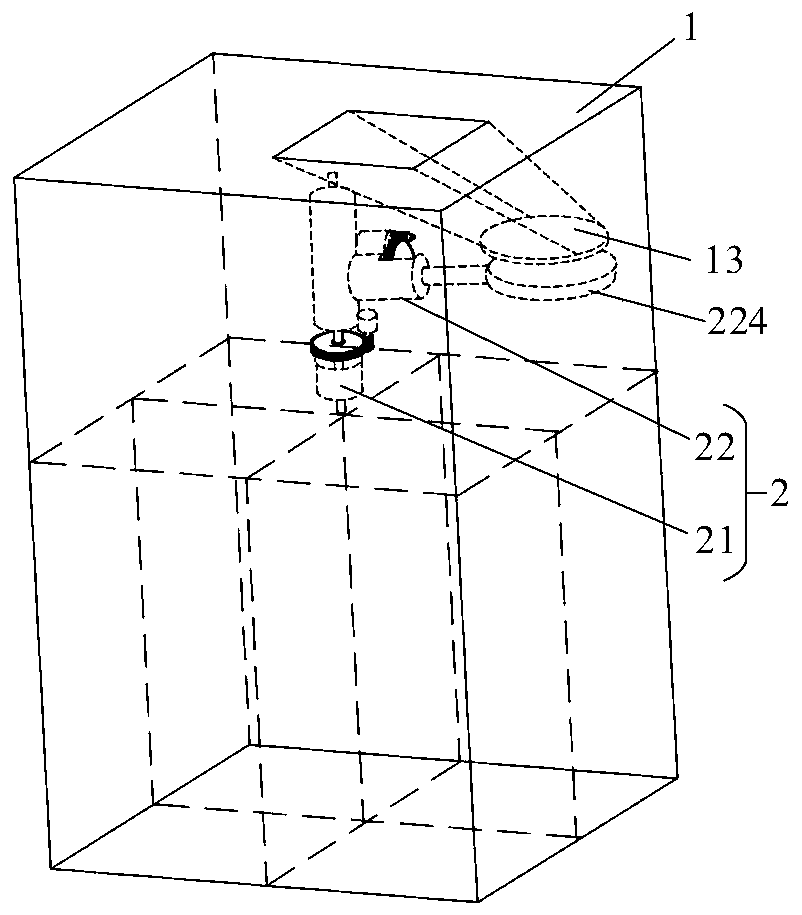

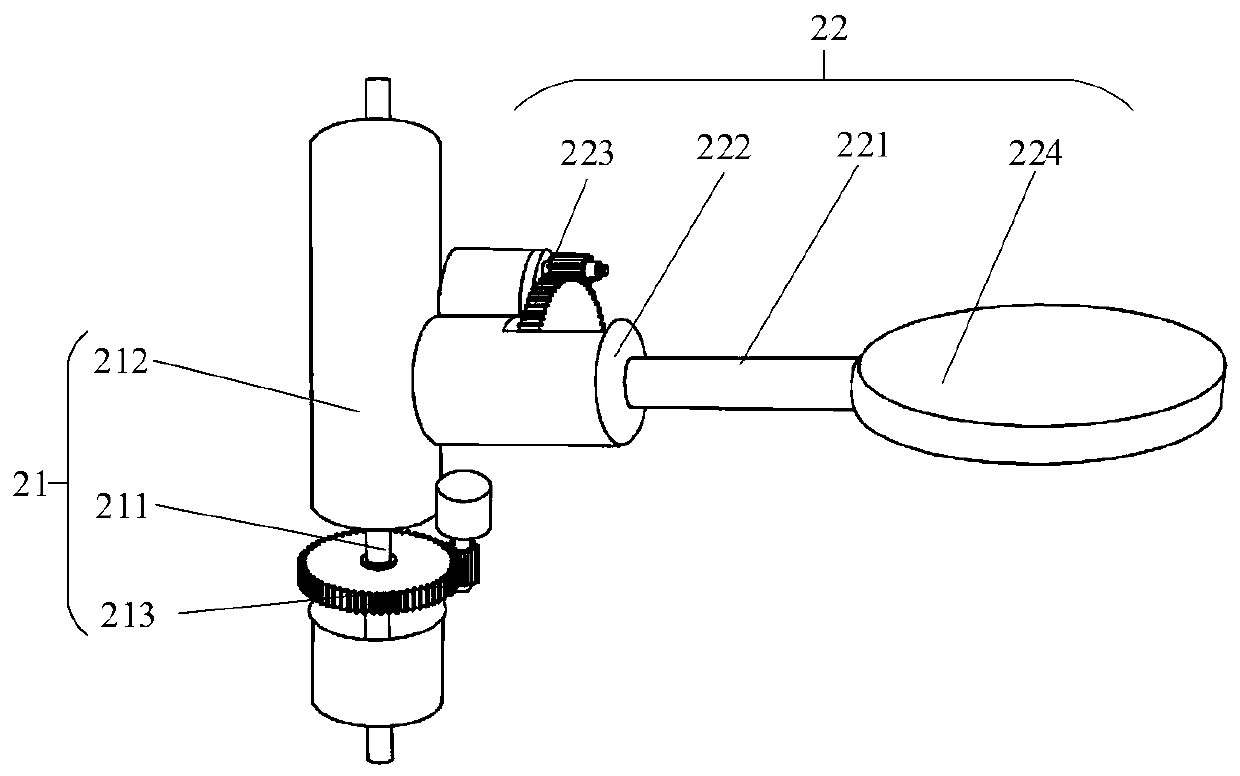

[0063] In order to clearly illustrate the intelligent garbage sorting method involved in the present invention, the garbage automatic sorting device applicable to the intelligent garbage sorting method is first described, see figure 1 and figure 2 The garbage automatic sorting device includes: a garbage bin body 1 and a rotating mechanism 2, the rotating mechanism 2 is arranged in the garbage bin body 1, and the garbage bin body 1 is provided with a garbage insertion port 11. A plurality of garbage storage boxes 12 are arranged in the garbage box body 1, and the garbage storage boxes 12 are used for accommodating corresponding types of garbage. Wherein, the number of garbage storage bins 12 is not specifically limited, and can be designed according to actual conditions.

[0064] In a practical application scenario, the garbage delivery port 11 can be arranged on the upper cover of the garbage bin body 1 (such as figure 1 shown). In a preferred embodiment, the garbage deliv...

Embodiment 2

[0089] Based on the garbage automatic sorting device of the foregoing embodiment, refer to Figure 7 , the present embodiment provides a machine learning-based intelligent garbage classification method, the intelligent garbage classification method includes the following steps:

[0090] Step 101: Detecting the garbage to be sorted, and acquiring a detection signal matching the garbage to be sorted, so as to determine the type of the garbage to be sorted.

[0091] Wherein, the garbage automatic sorting device of this embodiment is mainly applied to the sorting of recyclable garbage, wherein, recyclable garbage includes metal, glass, paper and plastic, that is, the types of garbage to be sorted include metal garbage and non-metal garbage Rubbish, described non-metallic rubbish comprises glass rubbish, paper rubbish and plastic rubbish.

[0092] In this embodiment, multiple sensors may be used to obtain detection signals and / or image acquisition devices may be used to obtain ima...

Embodiment 3

[0130] see Figure 11 , Figure 11 It is a schematic structural diagram of an automatic garbage sorting device provided by an embodiment of the present invention. The garbage automatic sorting device in this embodiment includes one or more processors 41 and memory 42 . in, Figure 11 A processor 41 is taken as an example.

[0131] Processor 41 and memory 42 can be connected by bus or other means, Figure 11 Take connection via bus as an example.

[0132] Memory 42, as a non-volatile computer-readable storage medium based on an intelligent garbage classification method, can be used to store non-volatile software programs, non-volatile computer-executable programs and modules, such as the machine-based Learned intelligent garbage classification methods and corresponding program instructions. The processor 41 executes various functional applications and data processing of the intelligent garbage classification method based on machine learning by running the non-volatile sof...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com