Rock-fill concrete dam construction joint impervious structure and construction method thereof

A technology of rockfill concrete and a construction method, which is applied in the field of rockfill concrete dams, can solve the problems of decreased durability of concrete, high comprehensive cost, and difficulty in adopting, and achieves the effects of simple construction process, saving project investment, and fast construction speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

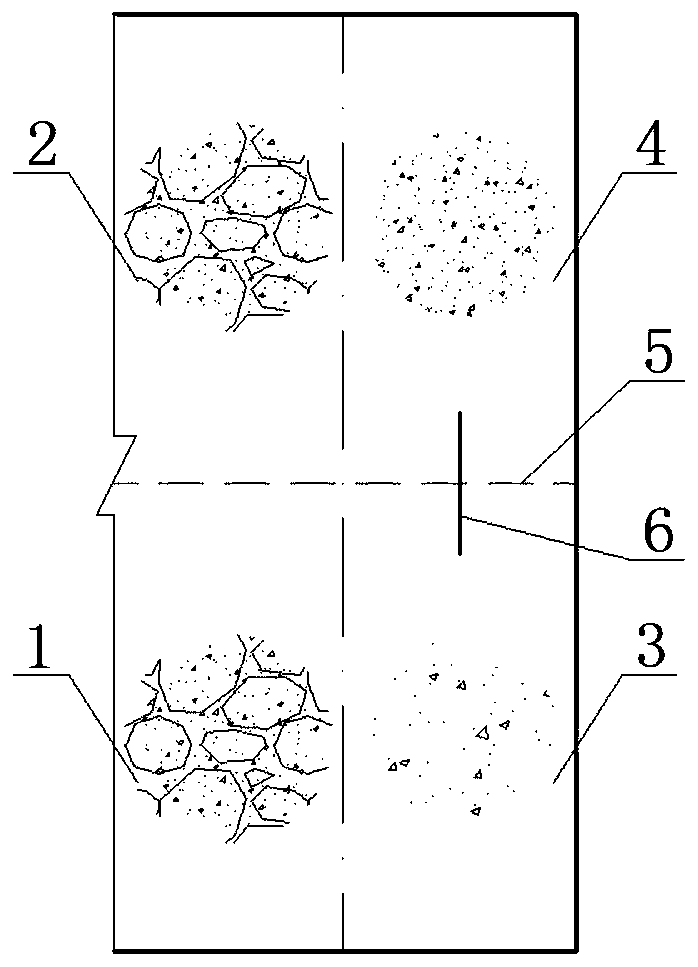

[0040] As mentioned above, for a construction joint anti-seepage structure of a rock-fill concrete dam, the lower rock-fill concrete 1 and the lower anti-seepage area 3 upstream are constructed first, and the construction joint surface 5 is formed after the construction is completed. After the self-compacting concrete is poured and before the initial setting of the concrete, at the middle position inside the lower anti-seepage area upstream of the construction joint surface 5, a waterstop 6 is arranged horizontally along the dam axis, and the waterstop 6 is arranged on the entire dam surface, vertically On the construction joint surface 5, it breaks when meeting the structural joints of the dam body.

[0041] Further, the waterstop 6 is made of 0.5mm thick galvanized iron sheet, 40cm wide, embedded 20cm inside the lower anti-seepage area 3, and leaks 20cm from the surface of the construction joint 5.

[0042] Secondly, after the installation of the waterstop 6 is completed, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com