Lower tube base buoyancy locking mechanism of lead-based reactor fuel component

A lead-based reactor and locking mechanism technology, applied in the directions of reactor fuel elements, fuel element assembly, reactors, etc., can solve the problem of fuel assemblies moving up and down, difficult to withstand high temperature, high corrosion and high radiation environment seismic load of liquid lead-bismuth coolant Comprehensive effect and other problems to achieve the effect of avoiding corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings, so as to better understand the purpose, features and advantages of the present invention. It should be understood that the embodiments shown in the drawings are not intended to limit the scope of the present invention, but only to illustrate the essence of the technical solutions of the present invention.

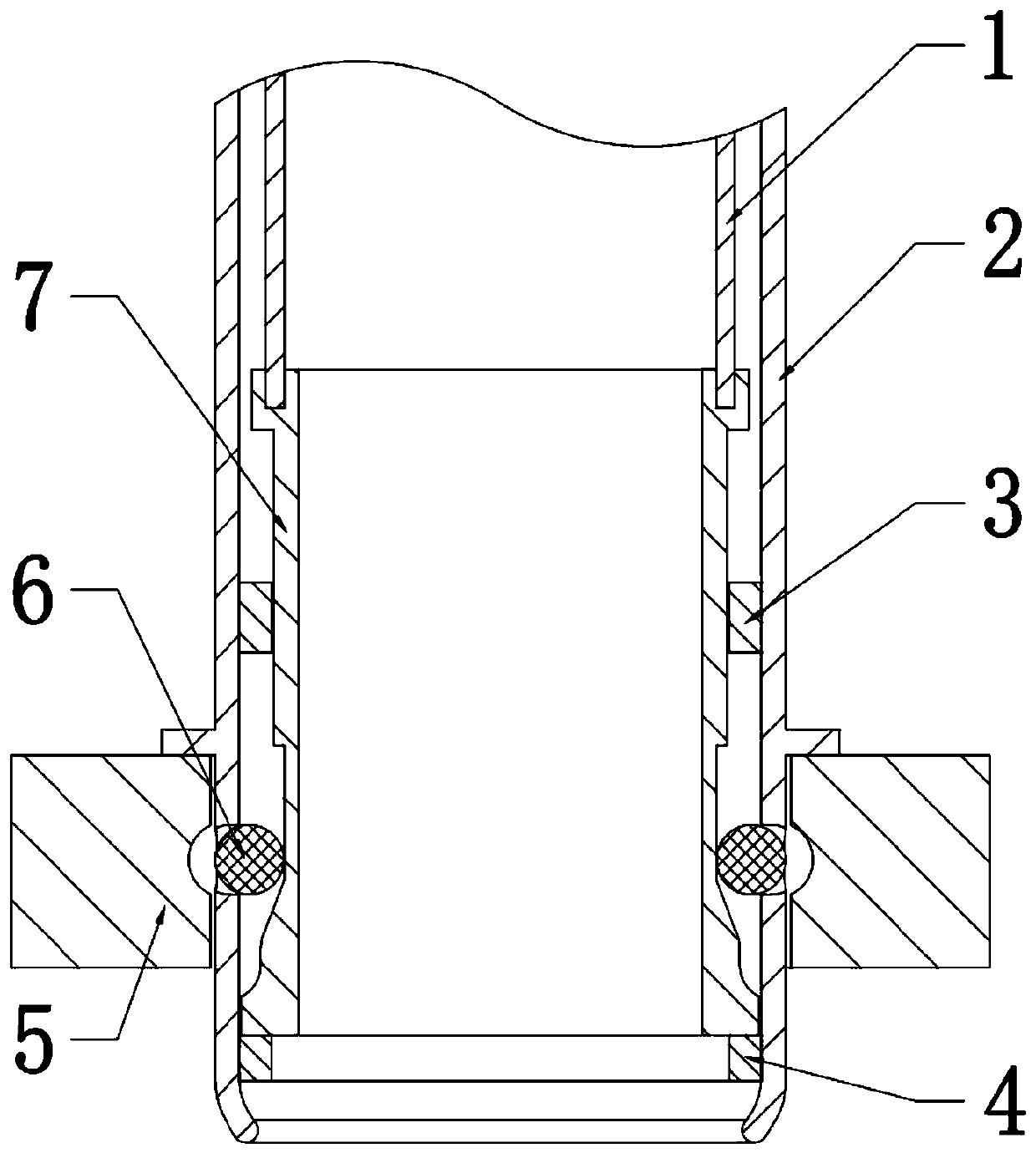

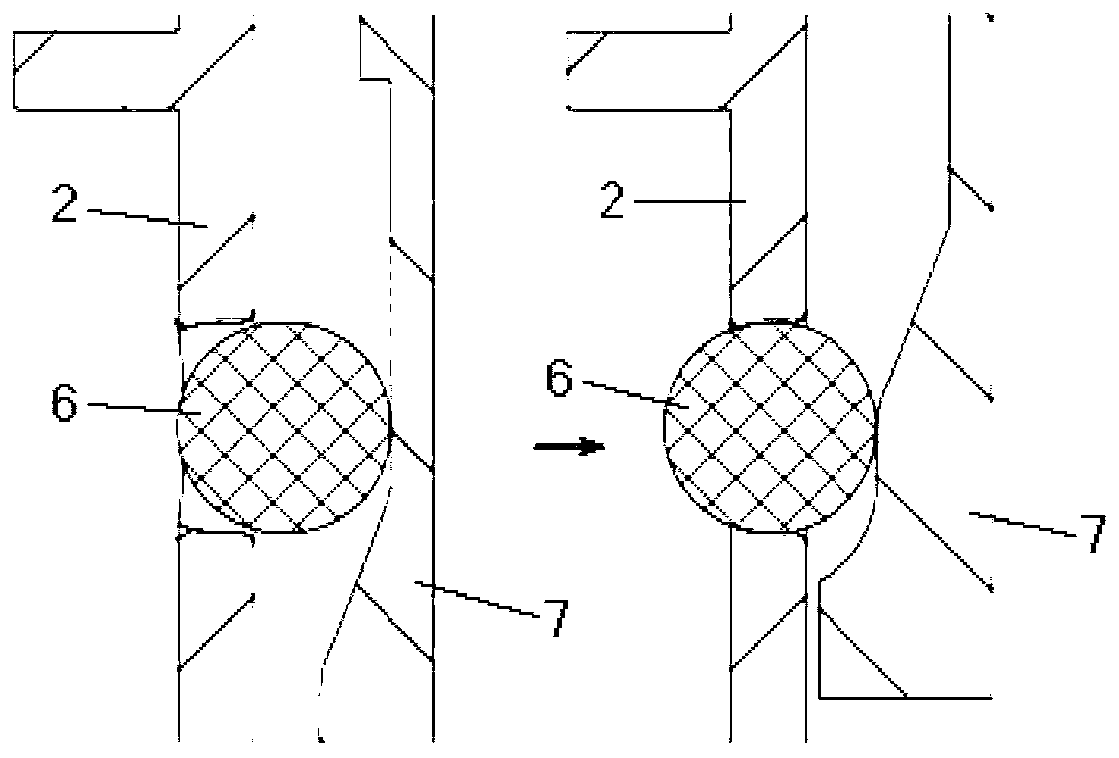

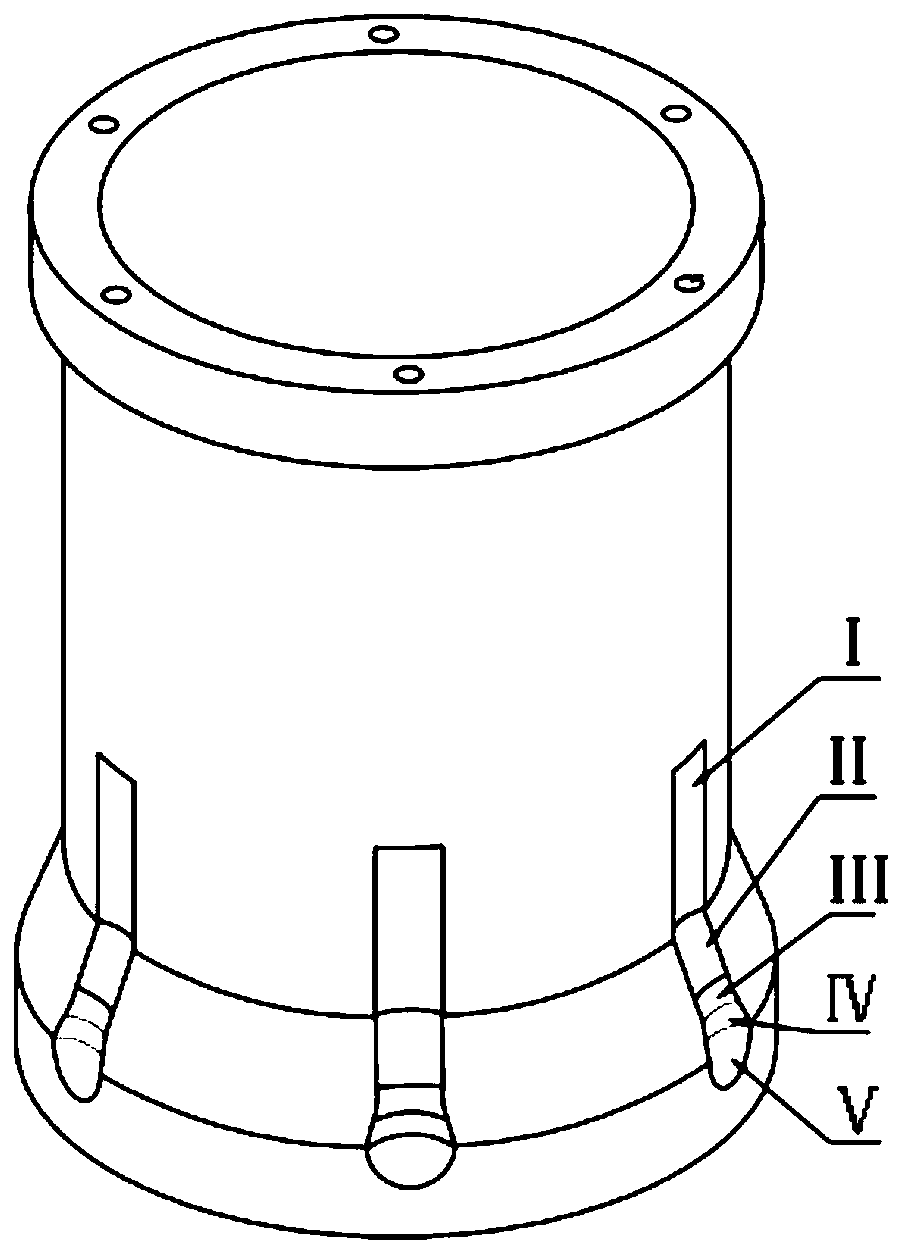

[0028] like figure 1As shown, the lower nozzle buoyancy locking mechanism of the lead-based reactor fuel assembly provided by the present invention includes: a core grid plate 5, and a through hole is provided on the core grid plate 5, and the holes in the core grid plate 5 There are several locking grooves on the inner wall along the circumferential direction; the lower pipe seat 2 is a cylindrical shell and forms the outer boundary of the buoyancy locking mechanism 100 of the lower pipe seat, and is used for positioning and inserting into th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com