Method for treating aflatoxin B1 in stored corn by using chlorine dioxide

A technology of aflatoxin and chlorine dioxide, which is applied in the direction of botany equipment and methods, applications, fruit hanging devices, etc., can solve the problems of low aflatoxin treatment capacity, lower toxin content, unsuitable degradation, etc., and achieve saving treatment Effects of time, growth inhibition, and spore germination inhibition of Aspergillus flavus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

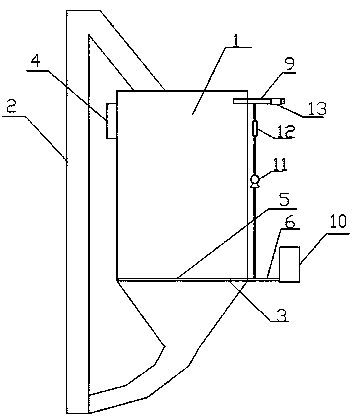

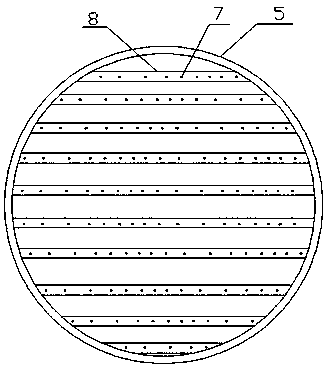

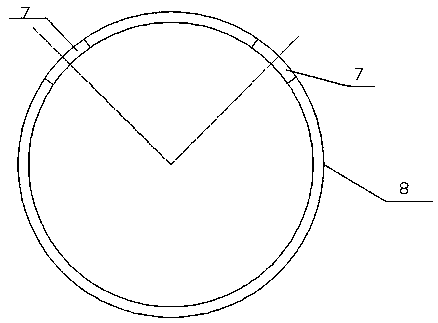

[0042] A kind of chlorine dioxide treatment of aflatoxin B in stored corn 1 The method comprises the steps of: laying corn in a closed storage room with a thickness of 1 cm, and the corn is a flow type; feeding chlorine dioxide gas with a concentration of 60 mg / L into the closed storage room, calculated per ton of corn, two Chlorine oxide gas is 2×10 3 L; Under the conditions of standard atmospheric pressure, humidity of 65% and temperature of 5°C, chlorine dioxide gas is fumigated in a closed storage room for 12 hours; finally, stop feeding chlorine dioxide gas, and feed dry air into the closed storage room, And set the corn storage conditions in the airtight storage room as follows: under standard atmospheric pressure, the humidity is 60%, and the temperature is 20°C.

[0043] In the closed storage room, the corn is stirred to make the corn flowable.

[0044] A chlorine dioxide gas concentration detector is installed in the airtight storage room.

[0045] The corn is corn...

Embodiment 2

[0047] A kind of chlorine dioxide treatment of aflatoxin B in stored corn 1 The method comprises the steps of: laying corn in a closed storage room with a thickness of 2 cm, and the corn is a flow type; feeding chlorine dioxide gas with a concentration of 100 mg / L into the closed storage room, calculated per ton of corn, two Chlorine oxide gas is 3×10 3 L; Under the conditions of standard atmospheric pressure, humidity of 75% and temperature of 25°C, chlorine dioxide gas is fumigated in a closed storage room for 24 hours; finally, stop feeding chlorine dioxide gas, and feed dry air into the closed storage room. And set the corn storage conditions in the airtight storage room as follows: under standard atmospheric pressure, the humidity is 75%, and the temperature is 18°C.

[0048] In the airtight storage room, the corn is conveyed and conveyed so that the corn is flowing.

[0049] A chlorine dioxide gas generator is installed outside the airtight storage room, and the chlor...

Embodiment 3

[0053] A kind of chlorine dioxide treatment of aflatoxin B in stored corn 1 The method comprises the steps of: laying corn in a closed storage room with a thickness of 2 cm, and the corn is a flow type; feeding chlorine dioxide gas with a concentration of 70 mg / L into the closed storage room, calculated per ton of corn, two Chlorine oxide gas is 2.2×10 3 L; Under the conditions of standard atmospheric pressure, humidity of 68% and temperature of 10°C, chlorine dioxide gas is fumigated in a closed storage room for 15 hours; finally, stop feeding chlorine dioxide gas, and feed dry air into the closed storage room. And set the corn storage conditions in the airtight storage room as follows: under standard atmospheric pressure, the humidity is 62%, and the temperature is 19°C.

[0054] In the airtight storage room, the corn is turned over by the hoist to make the corn flow.

[0055] A chlorine dioxide gas generator is installed outside the airtight storage room, and the chlorine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com