Antarctic krill canned food and making method thereof

A technology of Antarctic krill and canning, which is applied in the field of food processing and quality control, can solve the problems of difficult development and easy long-term storage, and achieve the effects of industrial production, low cost and simple processing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

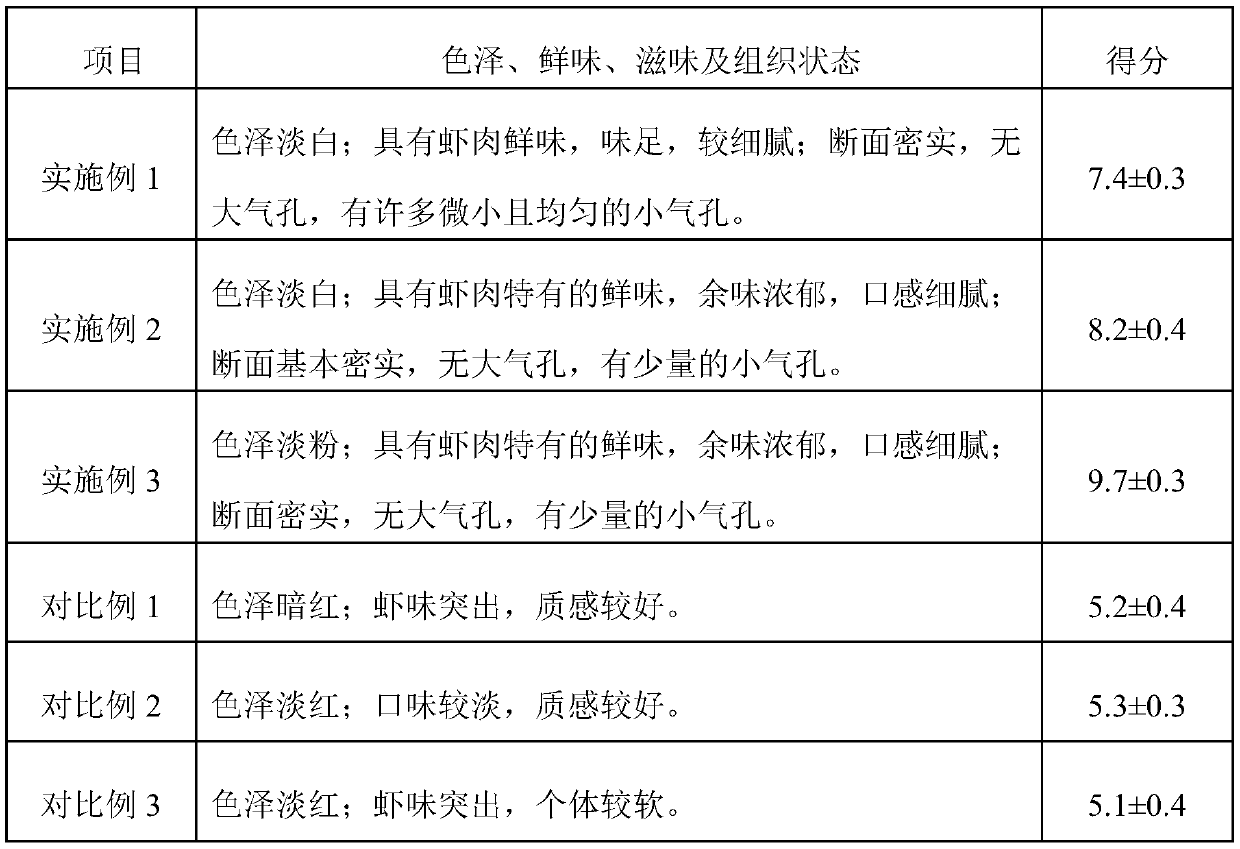

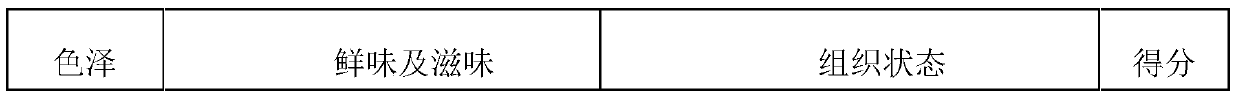

Examples

Embodiment 1

[0019] 1 canned raw material formula: Antarctic krill 90% (w / w), edible oil 4.5% (w / w), chicken essence 0.5% (w / w), salt 3.0% (w / w), ferrous gluconate 0.5% (w / w), citric acid 0.5% (w / w), liquor 0.5% (w / w) and oyster shell powder 0.5% (w / w).

[0020] 2 Processing technology:

[0021] 1) Citric acid treatment: thaw frozen Antarctic krill by soaking in a citric acid solution, the mass concentration of the citric acid solution is 0.5%, and the soaking time is 45 minutes;

[0022] 2) Pre-cooking in salt water: put the processed Antarctic krill into brine for pre-cooking, the concentration of salt in the brine is 3%, the concentration of citric acid is 0.5%, the pre-cooking time is 20min, remove and drain for later use;

[0023] 3) Stir-frying with ingredients: heat the pot and add vegetable oil, when the oil temperature reaches 125°C, add white wine, stir-fry for 2 minutes, then add the Antarctic krill, ferrous gluconate and oyster shell powder obtained in step 2) and stir-fry 3m...

Embodiment 2

[0026] 1 canned raw material formula: Antarctic krill 98.5% (w / w), edible oil 1% (w / w), chicken essence 0.05% (w / w), salt 0.1% (w / w), ferrous gluconate 0.05% (w / w), citric acid 0.1% (w / w), liquor 0.1% (w / w) and oyster shell powder 0.1% (w / w).

[0027] 2 Processing technology:

[0028] 1) Citric acid treatment: thaw frozen Antarctic krill by soaking in a citric acid solution, the mass concentration of the citric acid solution is 0.1%, and the soaking time is 60 minutes;

[0029] 2) Pre-cooking in salt water: put the processed Antarctic krill into brine for pre-cooking, the concentration of salt in the brine is 0.1%, the concentration of citric acid is 0.1%, the pre-cooking time is 30min, remove and drain for later use;

[0030] 3) Stir-frying with mixed ingredients: Heat the pot and add vegetable oil. When the oil temperature reaches 145°C, add white wine, stir-fry for 3 minutes, then add Antarctic krill, ferrous gluconate and oyster shell powder obtained in step 2 and stir-fr...

Embodiment 3

[0033] 1 Canned raw material formula: Antarctic krill 92.5% (w / w), edible oil 3.5% (w / w), chicken essence 0.3% (w / w), salt 1.5% (w / w), ferrous gluconate 0.5% (w / w), citric acid 0.5% (w / w), liquor 0.5% (w / w), oyster shell powder 0.5% (w / w) and black pepper 0.2% (w / w).

[0034] 2 The processing technology is:

[0035] 1) Citric acid treatment: thaw frozen Antarctic krill by soaking in a citric acid solution, the mass concentration of the citric acid solution is 0.03%, and the soaking time is 5 minutes;

[0036] 2) Pre-cooking in salt water: put the processed Antarctic krill into brine for pre-cooking, the concentration of salt in the brine is 1.5%, the concentration of citric acid is 0.5%, the pre-cooking time is 5 minutes, remove and drain for later use;

[0037] 3) Stir-frying with mixed ingredients: heat the pot and add vegetable oil, when the oil temperature reaches 100°C, add white wine, stir-fry for 0.5min, add Antarctic krill, ferrous gluconate and oyster shell powder ob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com