Photosensor testing sorting machine

A technology for testing sorting machines and photosensitive devices, applied in sorting and other directions, can solve the problems that the production method cannot meet the requirements of high-speed, high-precision, high-reliability manufacturing technology, cannot promote mass production, and has low production efficiency. The effect of high reliability, high production efficiency and low error rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

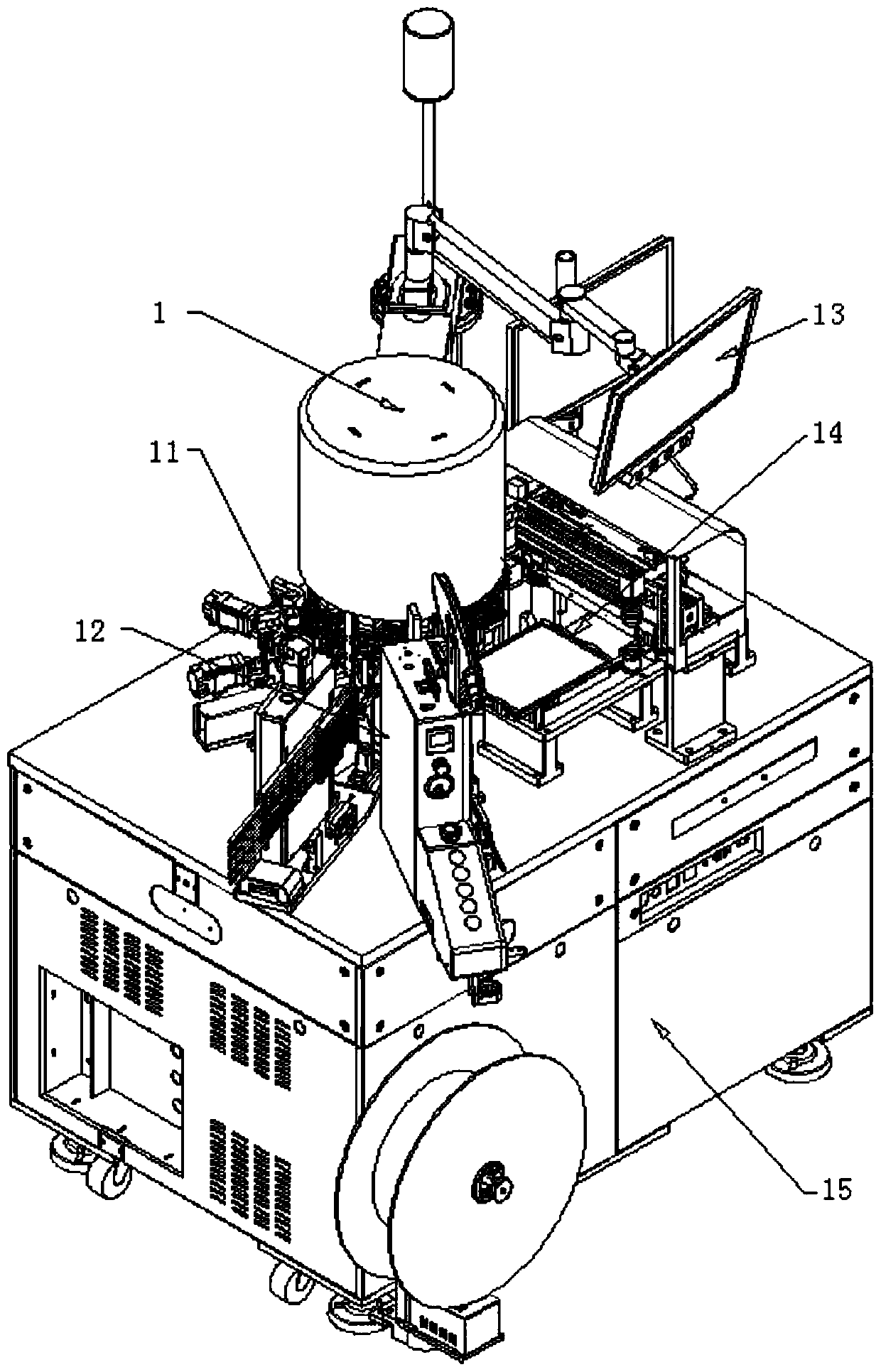

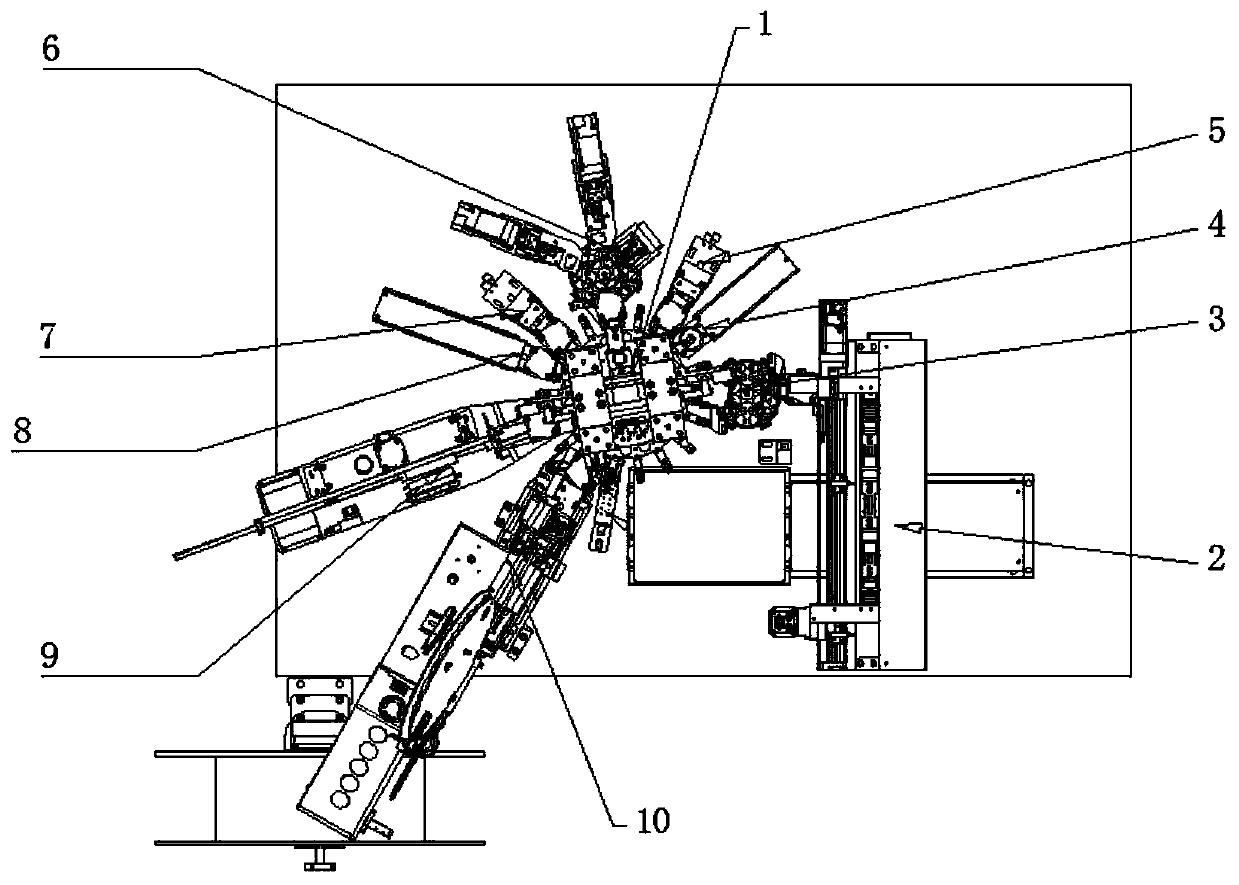

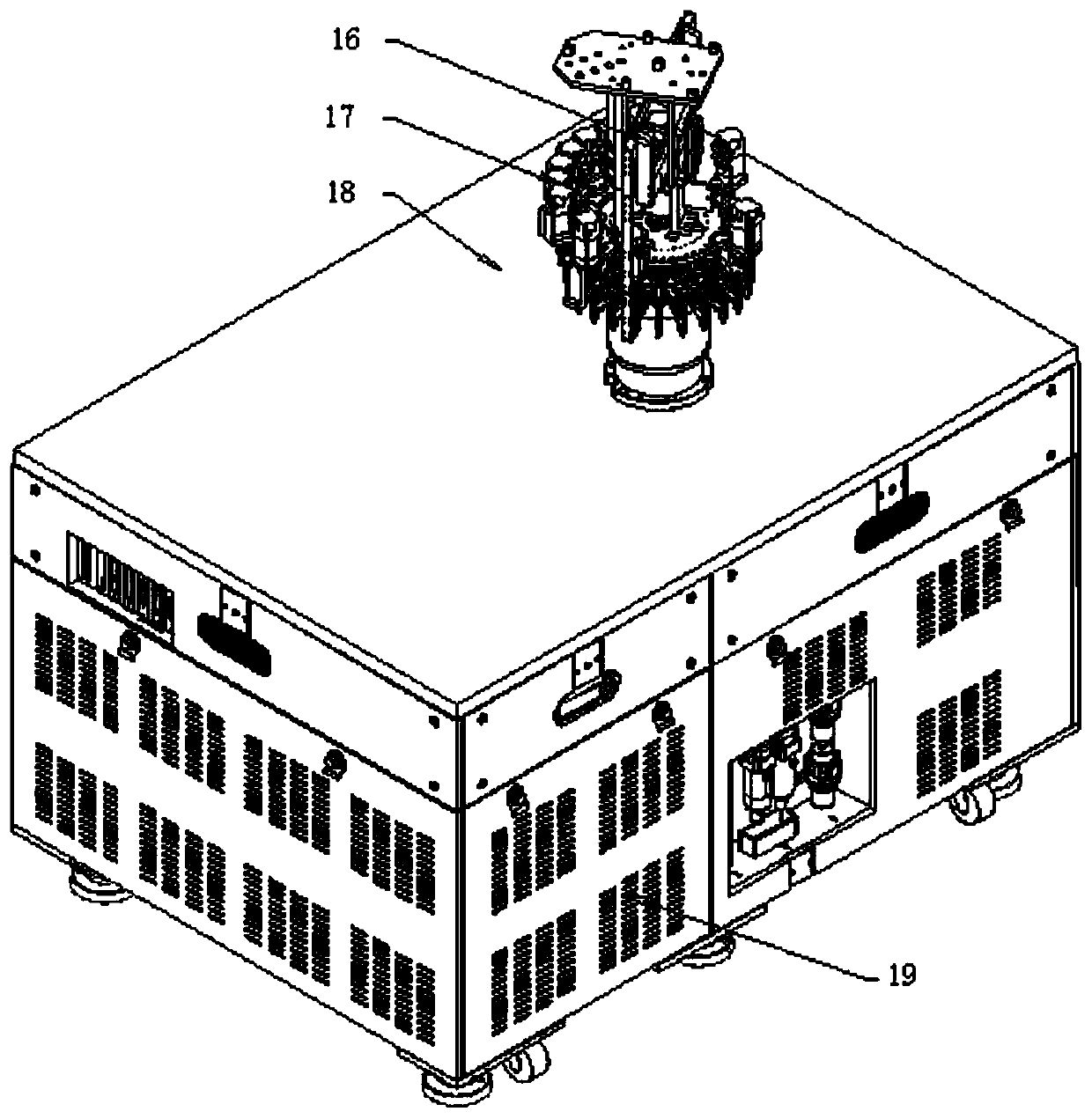

[0055] As an embodiment, the present invention proposes a photosensitive device test sorter, including:

[0056] The main tower turntable system systematically controls each module device;

[0057] For the material supply screening module, place the carrier tray with the device on the product delivery platform of the material supply screening module, the visual CCD device of the material supply screening module will identify the device, and the device pick-and-place suction nozzle will be selected from the carrier tray Products with the correct direction are sent to the device positioning inverted mold of the feeding transfer device;

[0058] The feeding transfer device, the feeding transfer device transfers the product to the working position of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com