Copper alloy liquid purifying device and method used for up-drawing continuous casting

A purification device and a technology for copper alloys, which are applied in the field of ultrafine copper alloy wire processing, can solve the problems of high wire breakage rate and insignificant effect, and achieve the effects of improving quality, being easier to implement, and reducing wire breakage rates.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

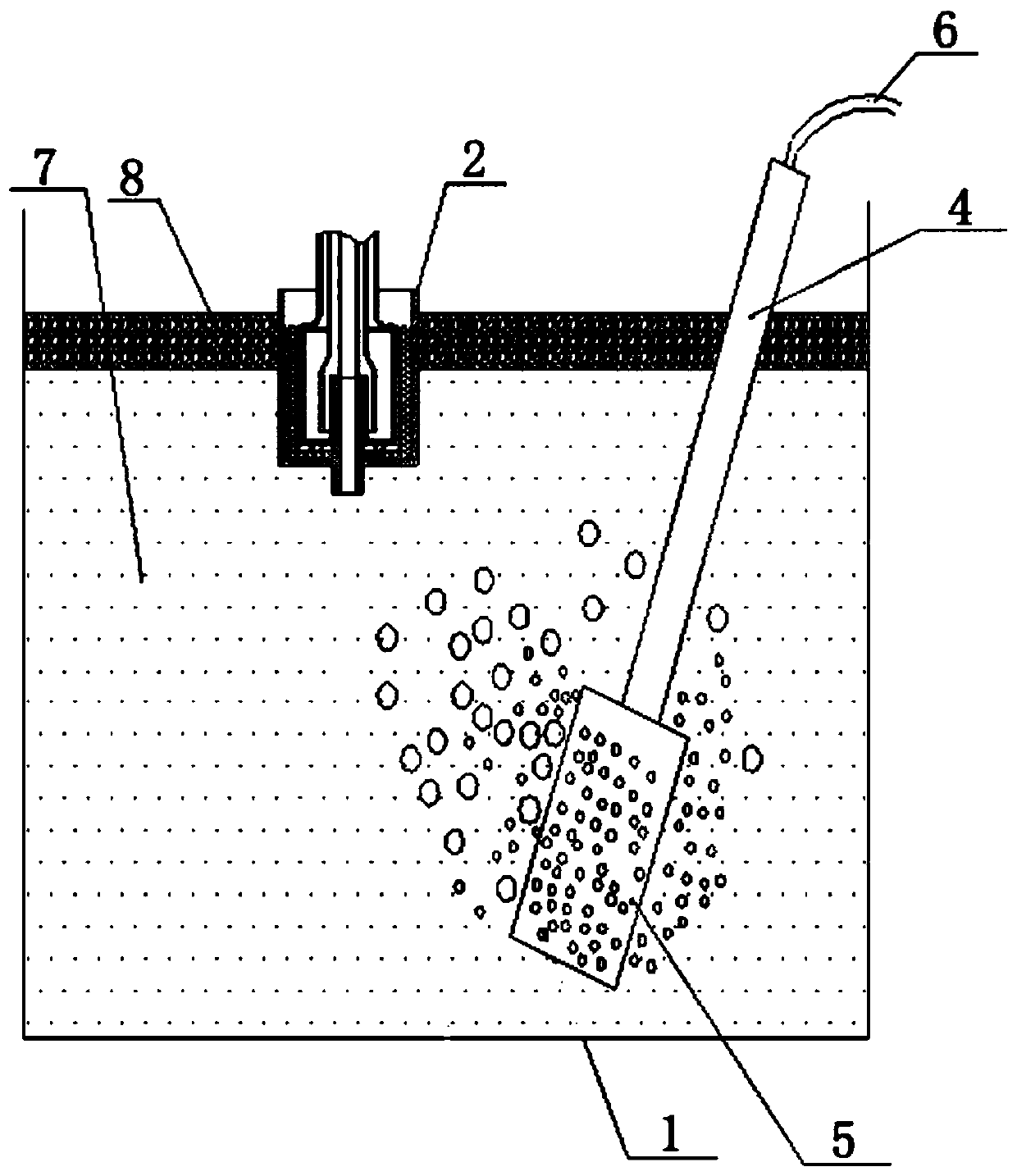

[0022] The copper alloy liquid purification device for upward continuous casting includes a bottom blowing impurity removal device located at the bottom of the upward continuous casting furnace insulation bin 1; the copper alloy liquid is treated with inert gas blown out by the bottom blowing impurity removal device, Removal of impurities and exhaust. After testing, the wire rod processed by the upward continuous casting mold has no pores and no impurities. After the drawing process and post-treatment process, 0.03mm ultra-fine copper alloy wire and ultra-fine copper alloy wire are prepared. No broken wires.

Embodiment 2

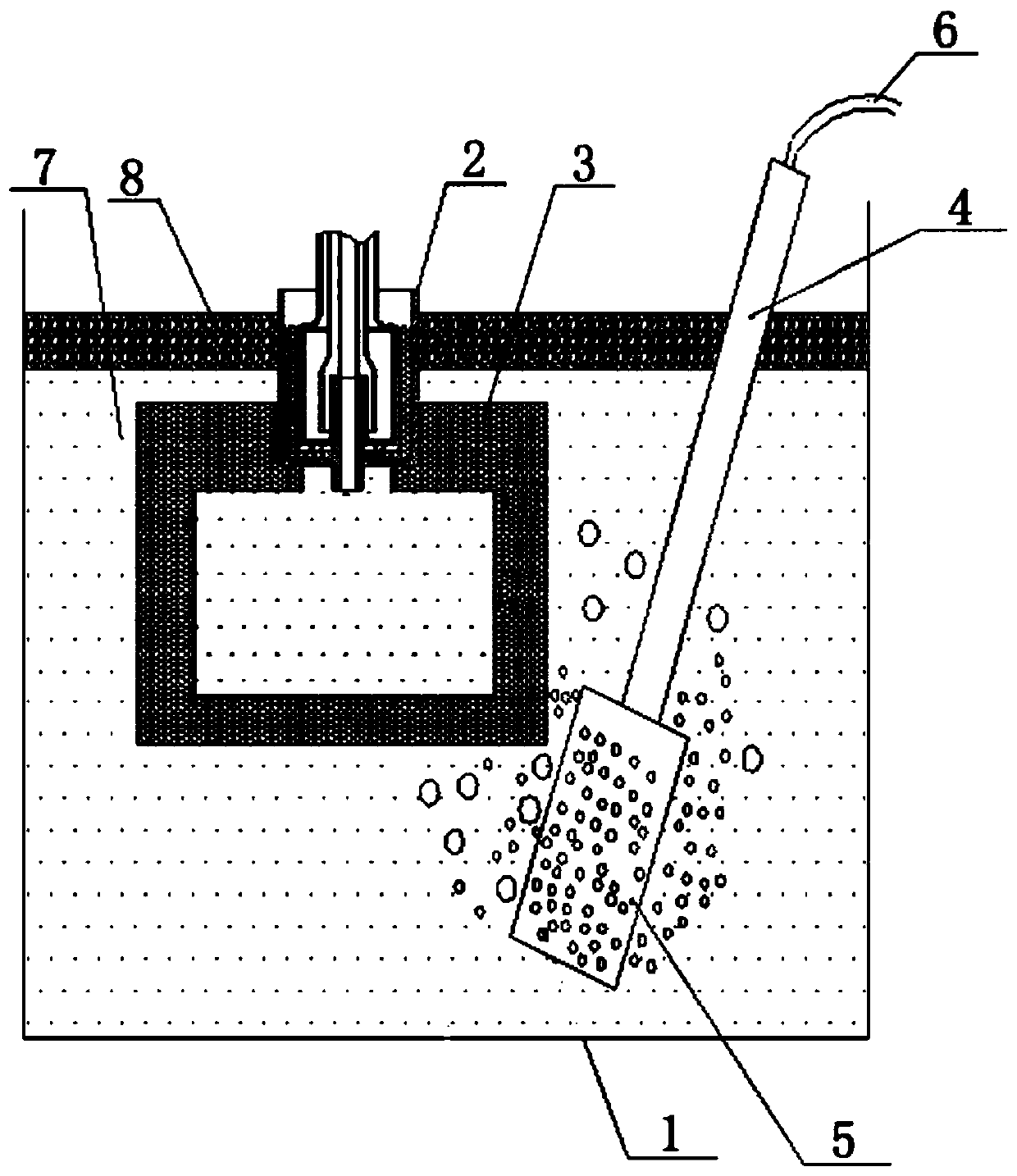

[0024] The copper alloy liquid purification device for upward continuous casting includes a filter purification device 3 arranged at the end of the upward continuous casting crystallizer 2, and the filter purification device 3 is located in the heat preservation chamber 1 of the upward continuous casting furnace; the copper alloy liquid passes through Filter and purify the device to remove impurities. After testing, the wire rod processed by the upward continuous casting crystallizer has no pores and no impurities. After the drawing process and post-treatment process, 0.04mm ultra-fine copper alloy wire is prepared. Ultra-fine The copper alloy wire has no broken wires.

Embodiment 3

[0026] The copper alloy liquid purification device for upward continuous casting includes a bottom blowing and impurity removal device installed at the bottom of the insulation chamber 1 of the upward continuous casting furnace, and a filter purification device installed at the end of the upward continuous casting crystallizer 2 3. The filtration and purification device 3 is located in the insulation bin 1 of the up-drawing continuous casting furnace; the copper alloy liquid is treated with the inert gas blown out by the bottom blowing impurity removal device for impurity removal and exhaust, and the copper alloy liquid is treated by the filtration and purification device. Remove impurities; after testing, the wire rod processed by the upward continuous casting crystallizer has no pores and no impurities, and then through the drawing process and post-treatment process, the ultra-fine copper alloy wire of 0.02mm is prepared, and the ultra-fine copper alloy wire is not broken. Si...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com