Acrylate material capable of being quickly cured by visible light and preparation method thereof

A technology of acrylates and acrylates, applied in the field of acrylate materials that can be quickly cured by visible light and its preparation, can solve the problems of unprotected, encapsulated insulation micro-crack detection and repair without effective solutions, etc. Power loss, increased operating temperature range, and less pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the purpose, technical solutions and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the examples. It should be understood that the specific examples described here are only used to explain the present invention and are not intended to limit the present invention. .

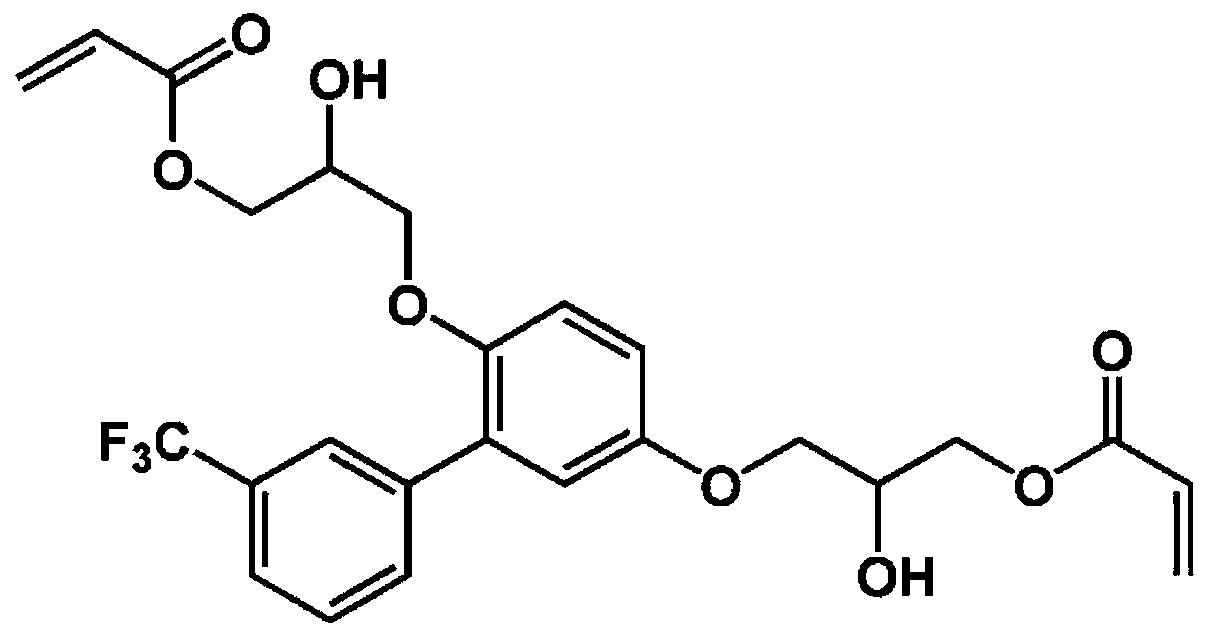

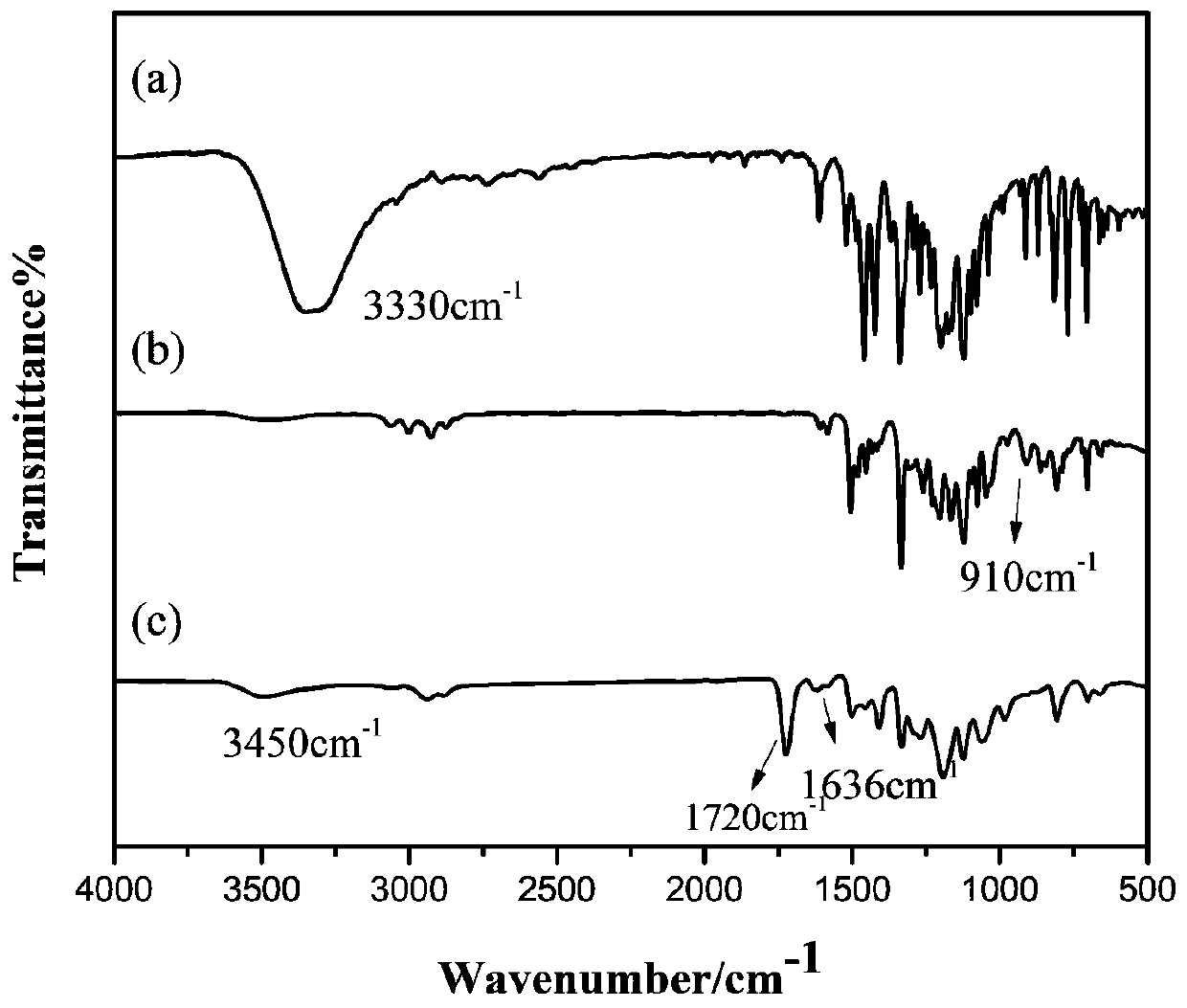

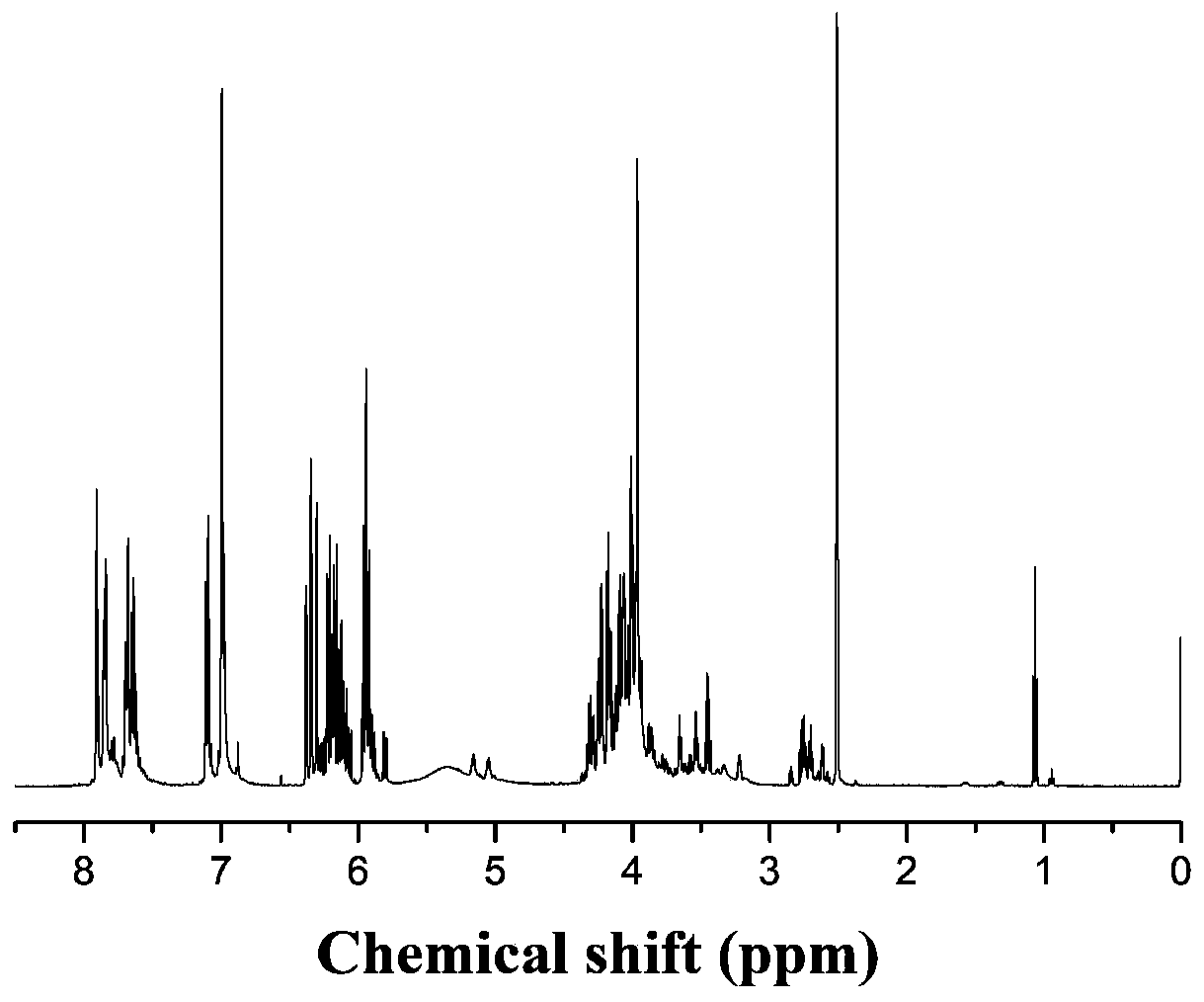

[0025] Such as figure 1 , 2 As shown in and 3, a fast visible light-curable acrylate material includes material A, material B, material C and material D, the material A is an acrylate monomer, and the material B is a commercially available adhesive Agent Bis-GMA, the C material is a commonly used bifunctional diluent monomer TEGDMA, the D material is CQ and DMAEMA, the mass and number ratio of each raw material is, A material x parts (0≤x≤7), B Material (7-x) parts, 3 parts of material C, and material D are each 1% of the total mass of material A and material C.

[0026] A method for preparing a fast visibl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

| Flexural modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com