Flexible pressure sensor based on polyimide substrate microstructure and its preparation method

A pressure sensor, polyimide technology, applied in the direction of fluid pressure measurement, instrument, and measurement force by changing ohmic resistance, can solve the problems of complex process and structure, large size of pressure sensor, poor applicability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

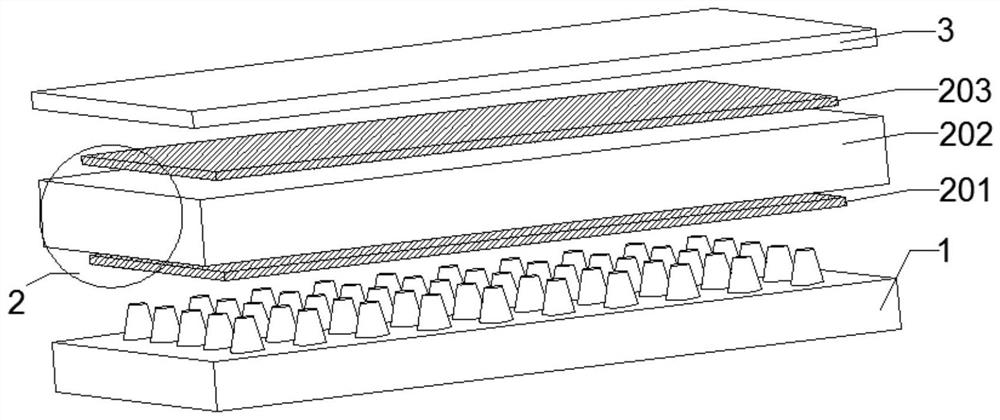

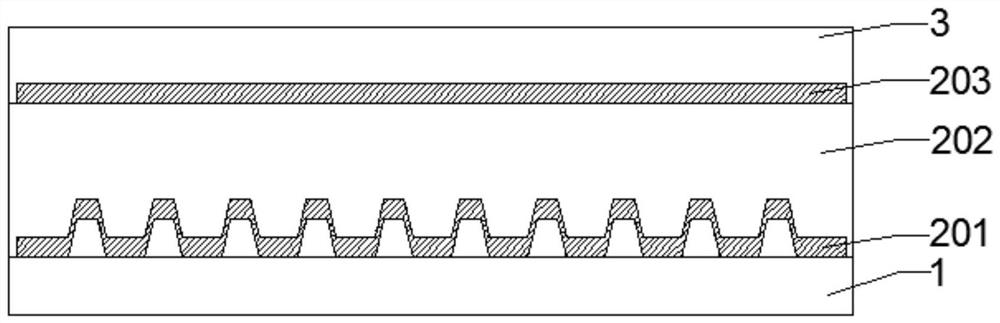

[0029] The invention provides a flexible pressure sensor based on the microstructure of the polyimide substrate. The pressure sensor has a film structure as a whole, and the whole body is made of flexible materials. Such as figure 1 As shown, the pressure sensor includes a lower flexible substrate 1, a force-sensitive structural layer 2 and an upper flexible packaging layer 3, and the three are closely attached. The force sensitive structure layer 2 includes a lower electrode layer 201 , a flexible piezoresistive material layer 202 and an upper electrode layer 203 . The sensor has the advantages of simple structure and easy array manufacturing. The preparation process is as follows:

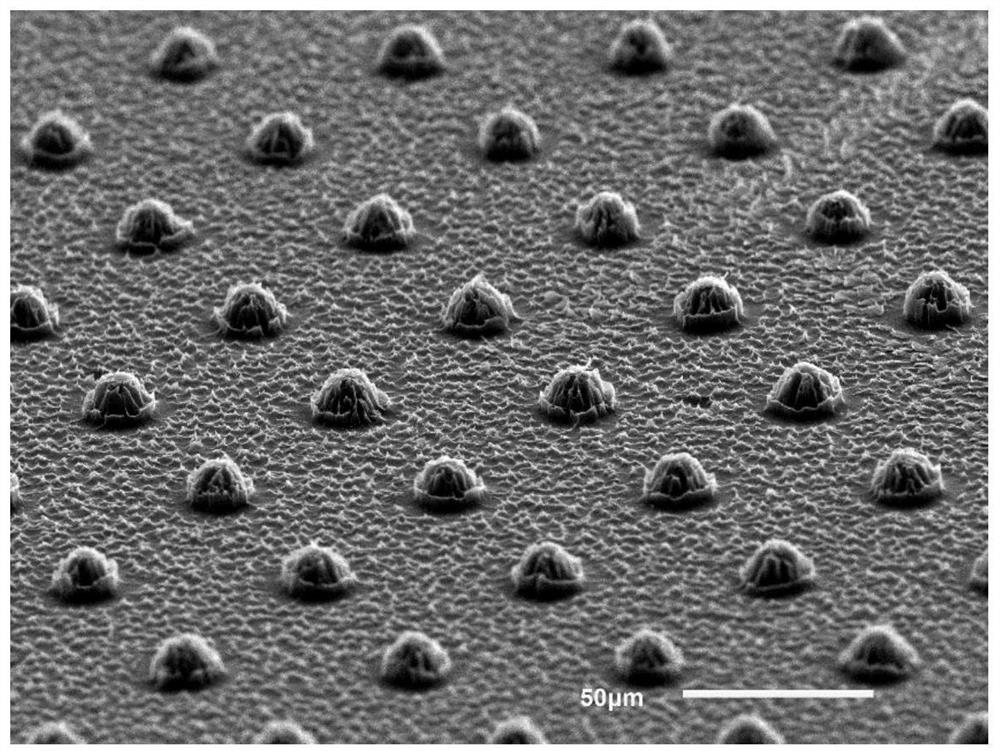

[0030] (1) The polyimide solution was spin-coated on the silicon wafer, and the curing temperature and time were 120°C for 30 min, 180°C for 30 min and 250°C for 30 m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| etching power | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com