Steaming and baking cooking method, steaming and baking cooking equipment, control method of steaming and baking cooking equipment and storage medium

A technology of cooking equipment and cooking methods, applied in the direction of program control, computer control, comprehensive factory control, etc., to achieve the effect of increasing fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

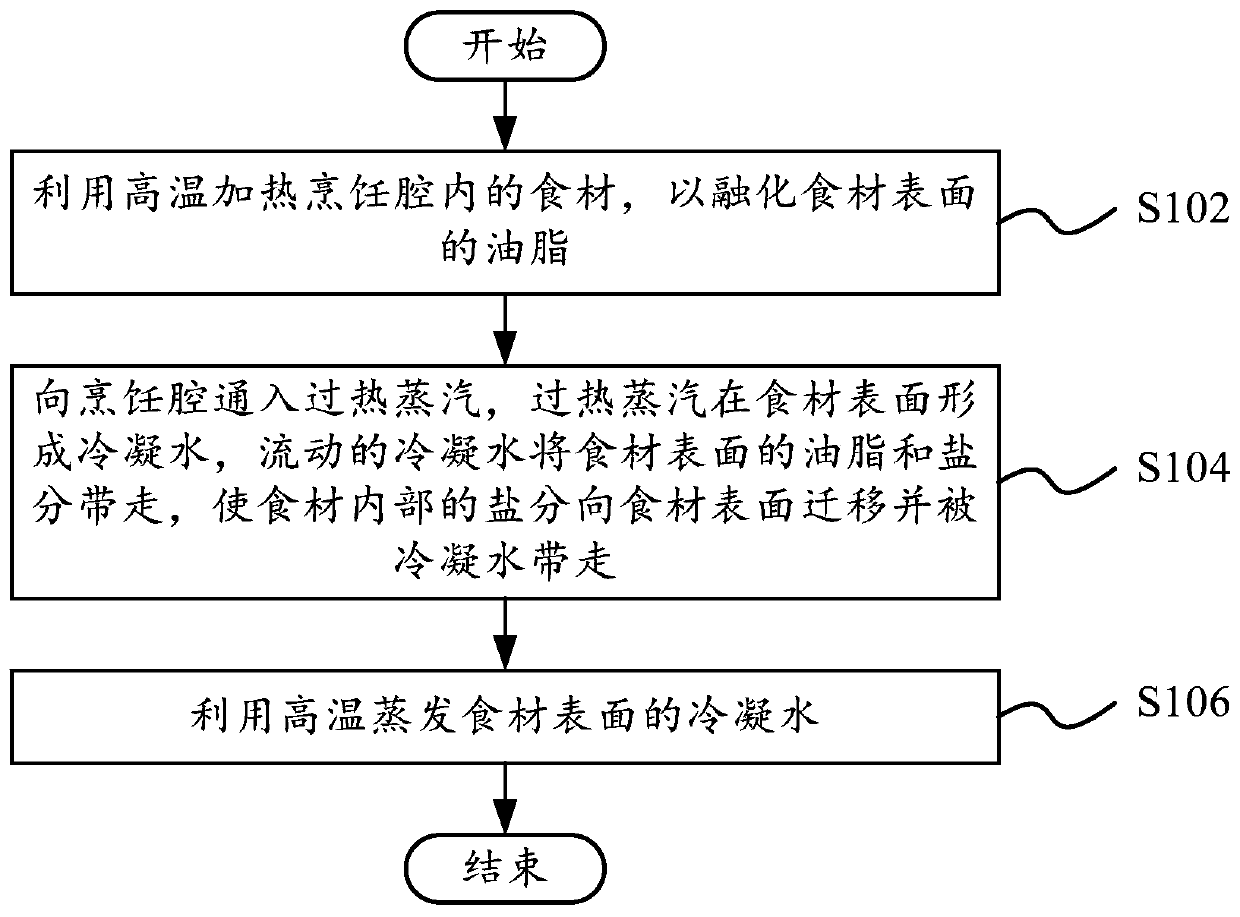

Method used

Image

Examples

Embodiment 1

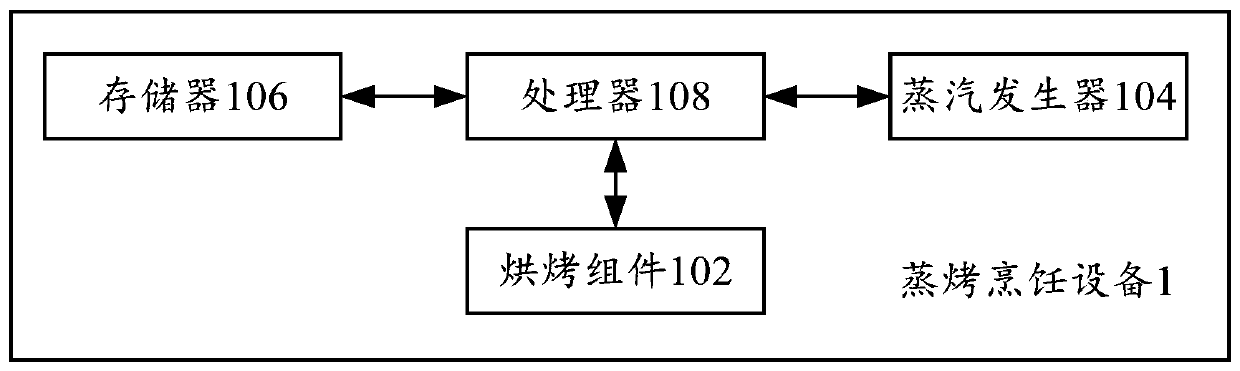

[0152] Processor 108 executes computer programs to:

[0153] Controlling the operation of the baking assembly 102 until the temperature in the cooking cavity rises from the room temperature T0 to the first temperature T1;

[0154] Start the steam generator 104, and control the operation of the baking assembly 102, so that the temperature in the cooking cavity is maintained at the first temperature interval T2 within the first time period t2, and any temperature value in the first temperature interval T2 is greater than or equal to the first temperature T1;

[0155] Turn off the steam generator 104, and control the operation of the baking assembly 102, so that the temperature in the cooking cavity enters the second temperature range T3, and any temperature value in the second temperature range T3 is greater than any temperature in the first temperature range T2 value.

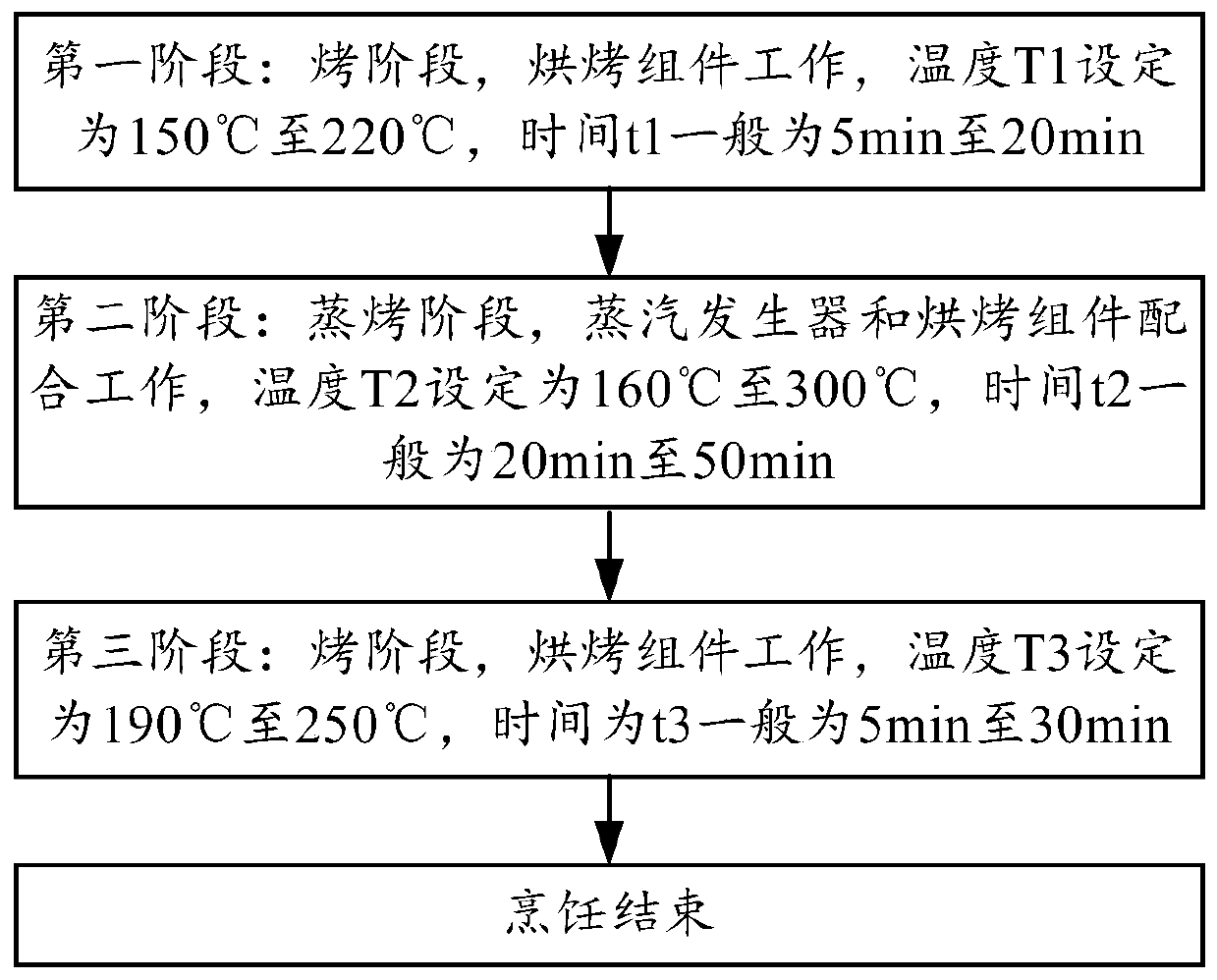

[0156] In this example, the cooking process is as image 3 As shown, the cooking curve is as Figure 4 sh...

Embodiment 2

[0158] Processor 108 executes computer programs to:

[0159] Controlling the operation of the baking assembly 102 until the temperature in the cooking cavity rises from the room temperature T0 to the first temperature T1;

[0160] Determine that any temperature value in the first temperature range T2 is greater than the first temperature T1, and control the operation of the baking assembly 102 until the temperature in the cooking cavity enters the first temperature range T2, and any temperature value in the first temperature range T2 is greater than equal to the first temperature T1;

[0161] Start the steam generator 104, and control the operation of the baking assembly 102, so that the temperature in the cooking cavity is maintained at the first temperature interval T2 within the first time period t2;

[0162] Turn off the steam generator 104, and control the operation of the baking assembly 102, so that the temperature in the cooking cavity enters the second temperature ra...

Embodiment 3

[0165] Processor 108 executes computer programs to:

[0166] Control the operation of the baking assembly 102 and the steam generator 104 until the temperature in the cooking cavity reaches the first temperature;

[0167] Controlling the operation of the baking assembly 102 and the steam generator 104 so that the temperature in the cooking cavity is maintained at a first temperature range within a first time period, and any temperature value in the first temperature range is greater than or equal to the first temperature;

[0168] The operation of the baking assembly 102 and the steam generator 104 is controlled so that the temperature in the cooking cavity enters the second temperature range.

[0169] The difference between the third embodiment and the first embodiment is that the baking assembly 102 and the steam generator 104 are operated simultaneously in the three stages, that is, superheated steam is used for the whole process of cooking. For the temperature and time va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com