Steel structure face plate tailor welding leveling device

A technology of leveling device and steel structure, applied in auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve the problems of difficult leveling, large force exerted by the panel, and large workload, so as to improve the efficiency of tailor welding. ,Easy leveling operation, reduce the effect of material loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

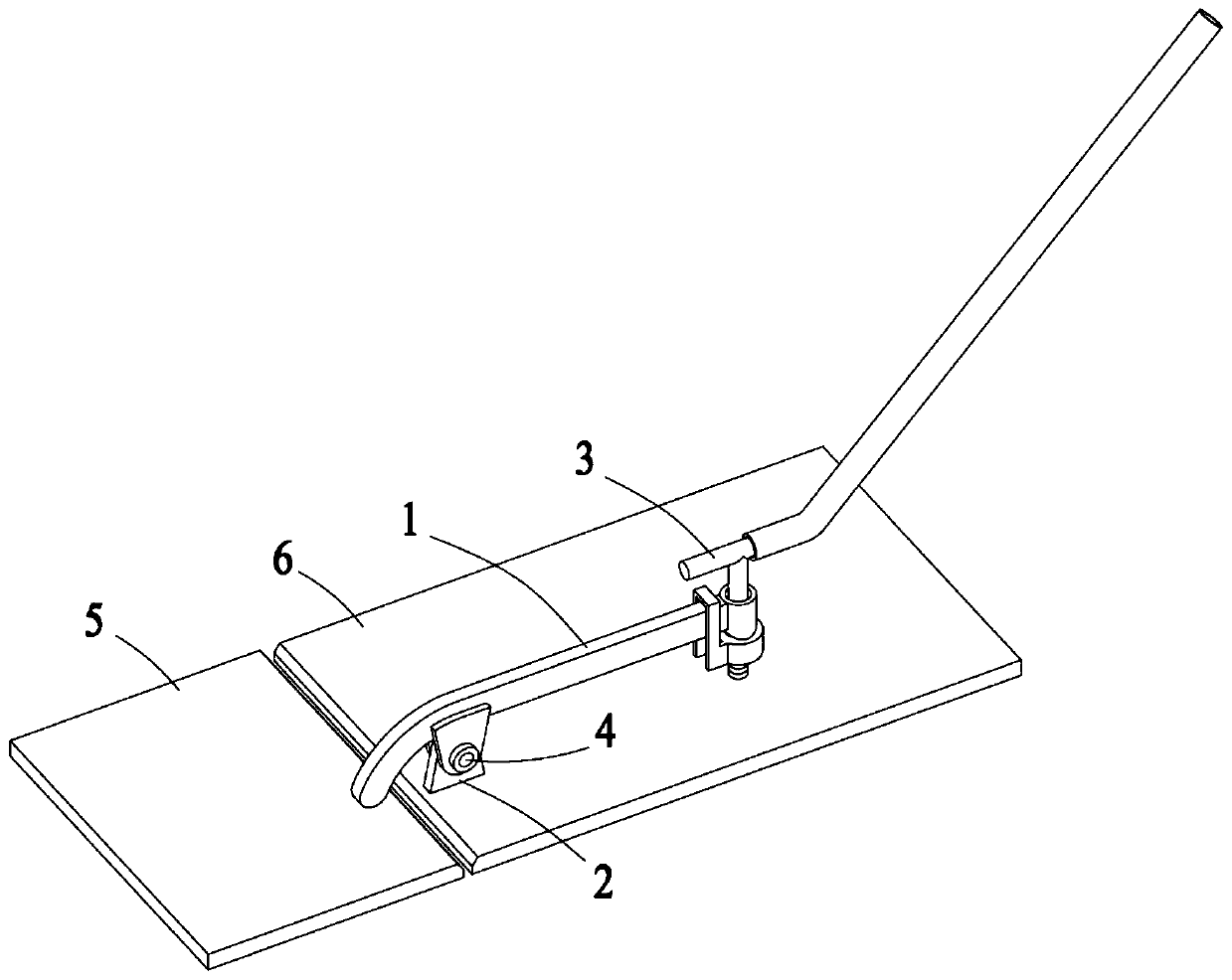

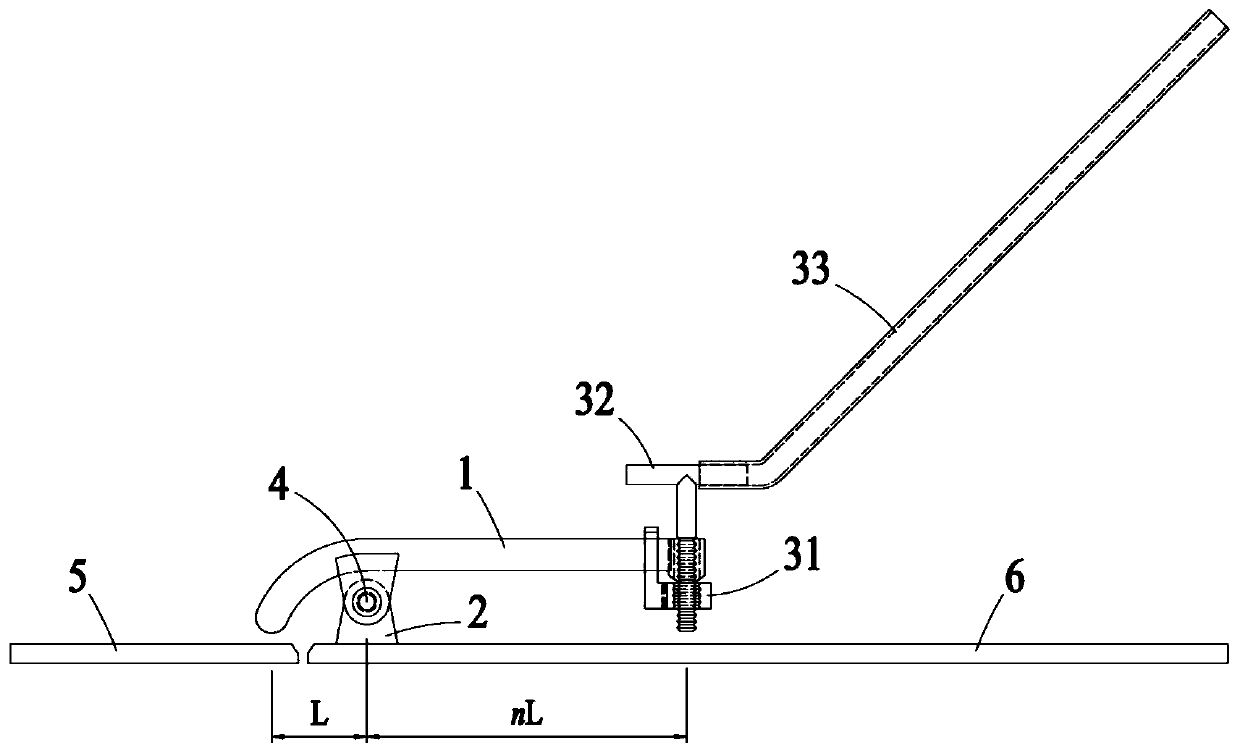

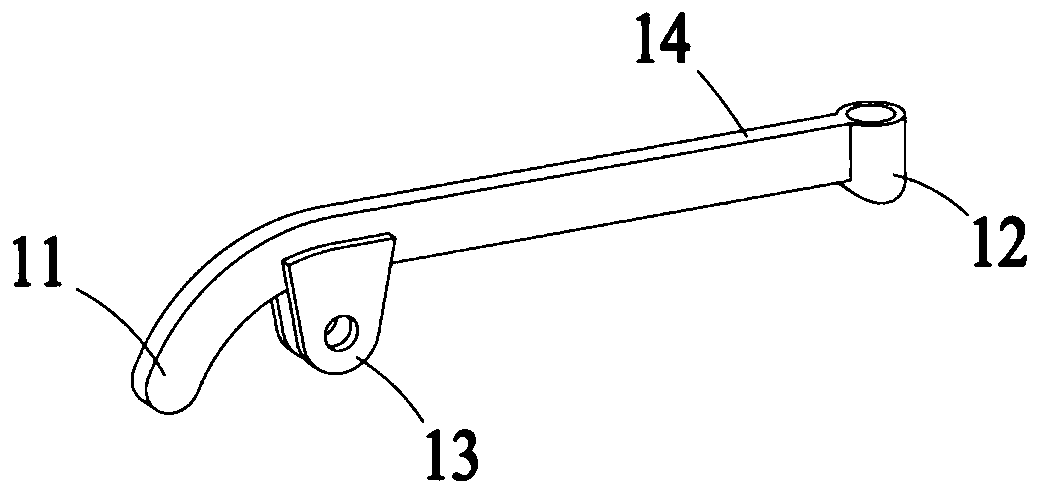

[0033] The specific embodiment of the present invention is as Figure 1-7 As shown, a tailor welding leveling device for a steel structure panel includes a pry bar 1 spanning the joint of steel plates. The reference steel plate 6, that is, the lower steel plate is provided with a fulcrum connecting plate 2 for hinged connection with the prying fulcrum 13 on the pry bar 1 . One end of the pry bar 1 is provided with a pressure head 11, which is used to apply force to the steel plate 5 to be leveled, that is, the steel plate at a high place. The other end of the pry bar 1 is provided with a bushing 12 for connecting the rotating force applying mechanism 3 .

[0034] By hingedly connecting the prying fulcrum 13 on the crowbar 1 with the fulcrum connecting plate 2, a lever structure with both ends capable of swinging up and down and in opposite swing directions is formed. With the jacking effect of the rotating force applying mechanism 3, the pressure head 11 of the pry bar 1 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com