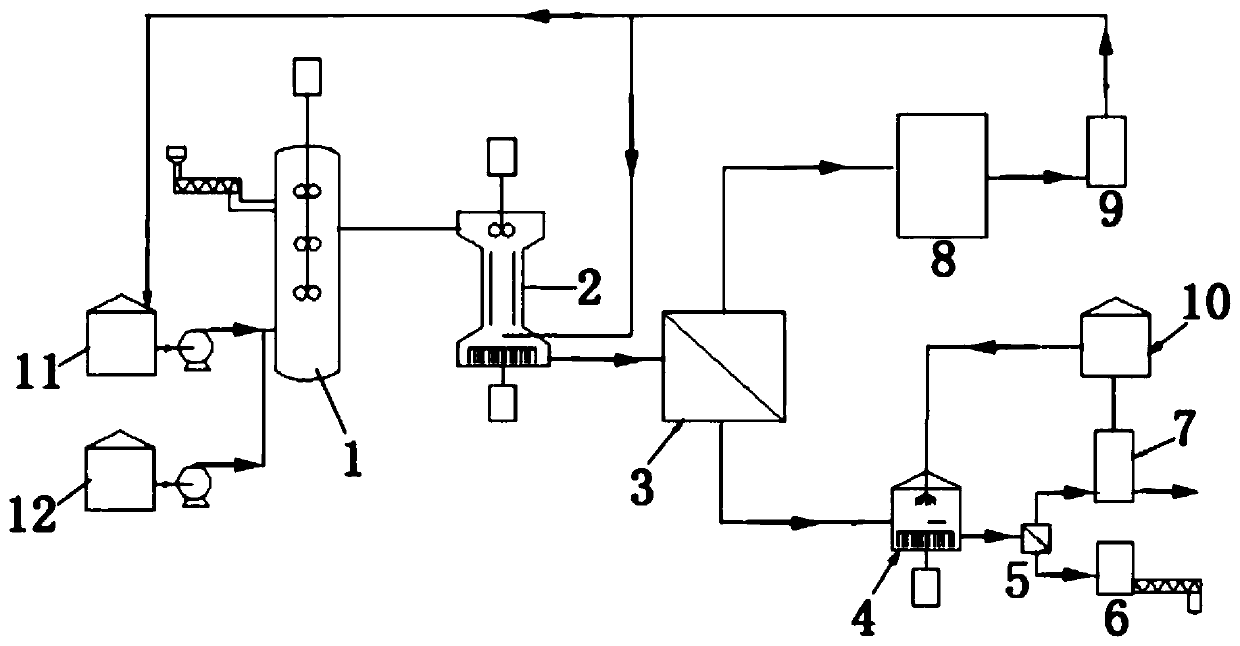

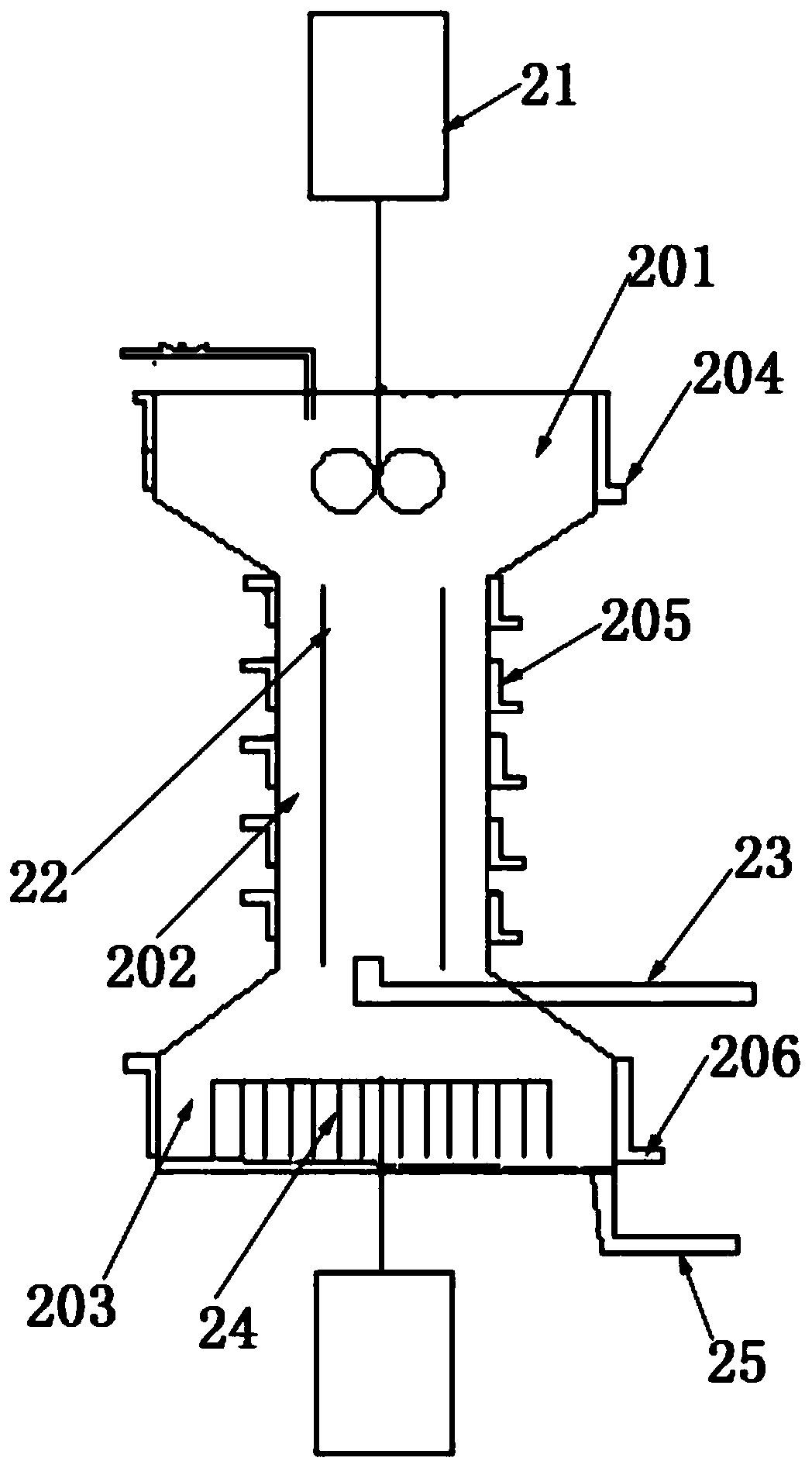

Device and process for continuously producing aluminum sulfate octadecahydrate

A technology of octadecadecahydrate and aluminum sulfate, which is applied in the direction of aluminum sulfate, aluminum compounds, aluminum sulfur compounds, etc., can solve problems such as inability to use directly, consume large energy, acidify water bodies or soils, etc., to improve resource utilization and reduce sulfuric acid The effect of high emission and resource utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] The raw material aluminum hydroxide has a purity of 98.0%, and also contains the following components in weight percentage: 0.65% Na 2 O, 0.87% SiO 2 , and the rest are impurities.

[0042] The mass concentration of dense phase waste sulfuric acid is 65.7%, and also contains 0.97% Fe element.

[0043] The mass concentration of dilute phase waste sulfuric acid is 39.2%, and also contains 0.03% Fe element.

[0044] Control the concentration of sulfuric acid in the mixture formed by the preliminary mixing of dilute-phase waste sulfuric acid and dense-phase waste sulfuric acid at 50-53%, and feed the preliminary mixture of the two kinds of waste sulfuric acid into the continuous tank reactor 1 together with aluminum hydroxide Internally (control the molar ratio of sulfuric acid and aluminum hydroxide in the initial mixture of two kinds of waste sulfuric acid to be 1:1.48~1.52), carry out continuous stirring reaction at 75°C and normal pressure, continuous tank reactor Th...

Embodiment 2

[0048] The raw material aluminum hydroxide has a purity of 98.0%, and also contains the following components in weight percentage: 0.65% Na 2 O, 0.87% SiO 2 , and the rest are impurities.

[0049] The mass concentration of dense phase waste sulfuric acid is 85.0%, and also contains 0.093% Fe element.

[0050]The mass concentration of dilute phase waste sulfuric acid is 20.2%, and also contains 0.02% Fe element.

[0051] Control the concentration of sulfuric acid in the mixture formed by the preliminary mixing of dilute-phase waste sulfuric acid and dense-phase waste sulfuric acid at 50-53%, and feed the preliminary mixture of the two kinds of waste sulfuric acid into the continuous tank reactor 1 together with aluminum hydroxide (control the molar ratio of sulfuric acid and aluminum hydroxide in the initial mixture of two kinds of waste sulfuric acid to be 1:1.50~1.52), carry out continuous stirring reaction at 95°C and normal pressure, continuous tank reactor The residence...

Embodiment 3

[0055] The raw material aluminum hydroxide has a purity of 98.1%, and also contains the following components in weight percentage: 0.63% Na 2 O, 0.67% SiO 2 , and the rest are impurities.

[0056] The mass concentration of dense phase waste sulfuric acid is 70.4%, and also contains 0.73% Fe element.

[0057] The mass concentration of dilute phase waste sulfuric acid is 27.4%, and also contains 0.13% Fe element.

[0058] Control the concentration of sulfuric acid in the mixture formed by the initial mixing of dilute-phase waste sulfuric acid and concentrated-phase waste sulfuric acid at 49-53%, and feed the preliminary mixture of the two kinds of waste sulfuric acid into the continuous tank reactor 1 together with aluminum hydroxide (control the molar ratio of sulfuric acid and aluminum hydroxide in the preliminary mixture of two kinds of waste sulfuric acid to be 1:1.50~1.52), carry out continuous stirring reaction at 85°C and normal pressure, continuous tank reactor The re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com