Sulfur-iron autotrophic denitrification device and application thereof

A technology of autotrophic denitrification and iron sulphur, applied in chemical instruments and methods, water pollutants, water/sludge/sewage treatment, etc., can solve the problems of large floor space, increased operating costs, and unfavorable removal of nitrogen and phosphorus. , to achieve the effect of saving operating costs, saving floor space, and avoiding hardening and replacement problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

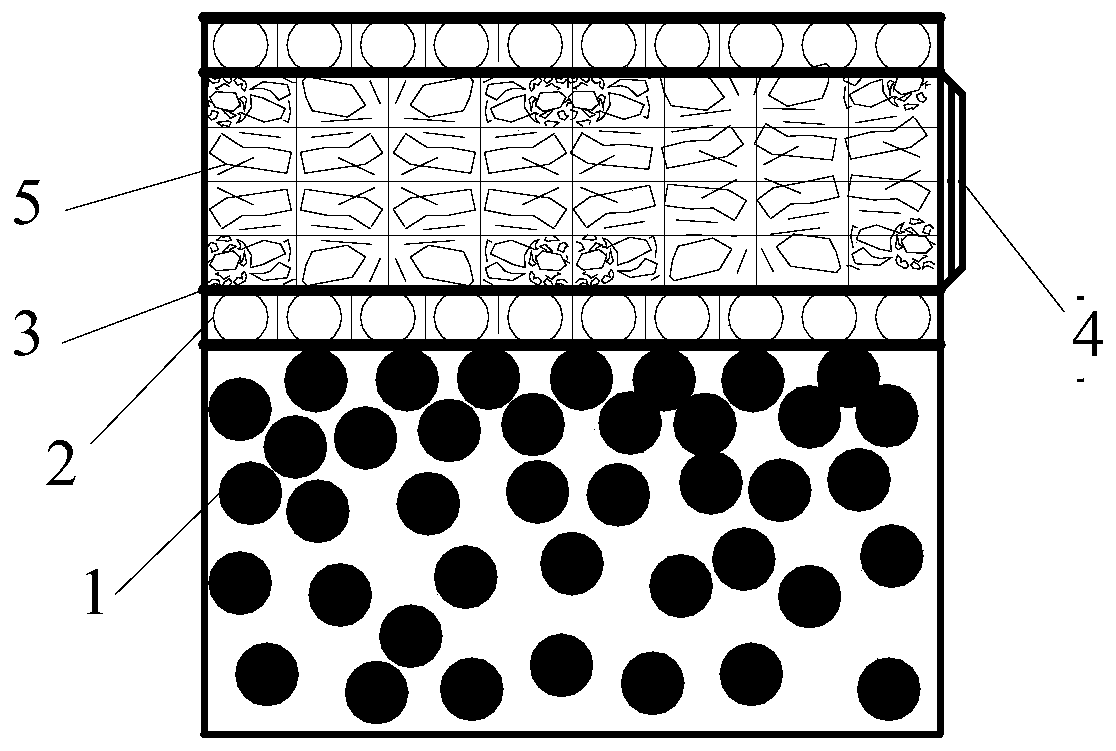

[0043] Embodiment 1: iron sulfur filler layer

[0044] The structure of the sulfur iron filler is as figure 1 As shown, the sulfur iron packing layer includes sulfur particles 1 and an iron packing layer, and the iron packing layer is provided with a supporting layer 3 up and down, and a screen is arranged in the middle, and a water distribution hole 2 is provided in the supporting layer; In the iron filler layer, iron filings 5 are placed in the screen, and iron filler replacement openings 4 are provided on the side of the iron filler layer. The iron filings 5 are placed in the screen and arranged in a multi-stage sulfur-iron arrangement, which is conducive to giving full play to the effect of iron chemical phosphorus removal, and when the iron filings are consumed and cannot meet the requirements of phosphorus removal, they can be carried out through the replacement opening The replacement of iron packing is convenient and quick, which effectively avoids the problems of...

Embodiment 2

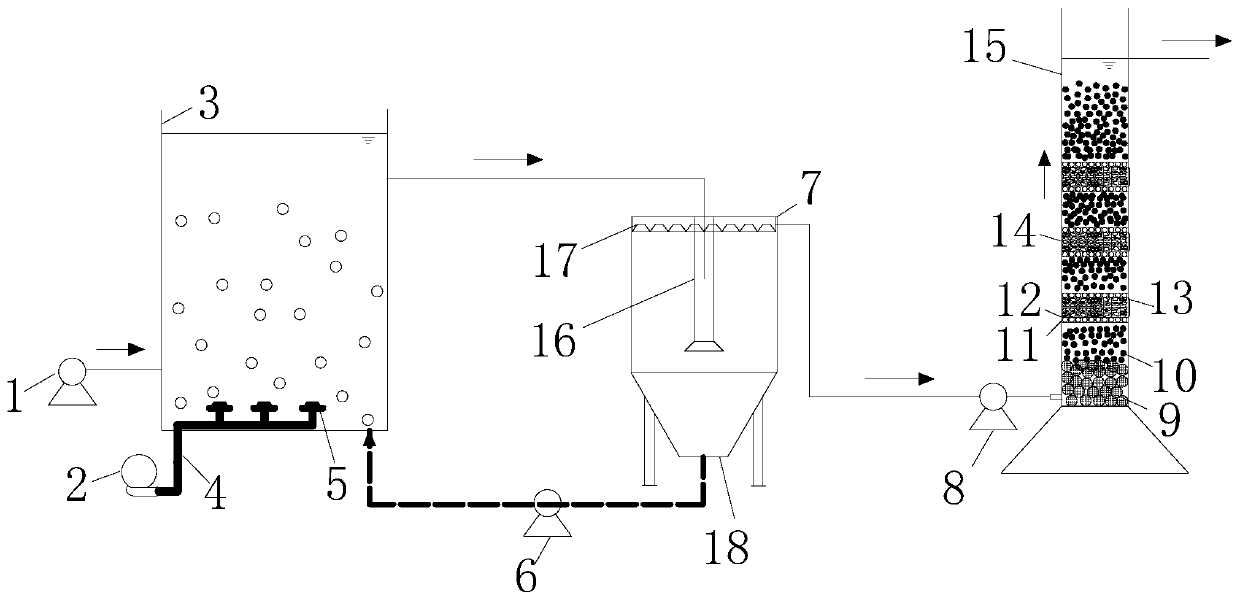

[0045] Embodiment 2: CAS / S-Fe autotrophic denitrification process

[0046] Such as figure 2 As shown, the reactor is made of acrylic plate, and the combined process includes an aeration tank 3, a sedimentation tank 7 and a sulfur iron autotrophic denitrification filter 15; the aeration tank 3 includes a water inlet, a water outlet and an aeration device; the water inlet is located at the lower part of the aeration tank, and is connected with the water inlet pump 1; The outside of the air tank 3 is connected to the aerator 5 through the aeration pipe 4 .

[0047] The sedimentation tank 7 is in an inverted cone shape, and the sedimentation tank 7 includes a diversion pipe 16, an outlet weir 17 and a mud collection bucket 18; The water outlets are connected; the outlet weir 17 is located at the top of the sedimentation tank 7; the mud collecting bucket 18 is located at the bottom of the sedimentation tank 7; connected; the sedimentation tank 7 is connected with the sulfur iro...

Embodiment 3

[0053] Embodiment 3: MBR / S-Fe autotrophic denitrification process

[0054] Such as Figure 8 As shown, the material of the reactor is an acrylic plate, the combined process includes an MBR pool 7 and an S-Fe filter tank 15, the effective volumes are respectively: 15L and 6L, and the MBR / S-Fe autotrophic denitrification device is sequentially equipped with MBR Pond 7 and sulfur-iron autotrophic denitrification filter 15; Described sulfur-iron autotrophic denitrification filter 15 is connected with MBR outlet pipe 6 by MBR outlet water pump 8; Described sulfur-iron autotrophic denitrification filter 15 is provided with packing layer , the packing layer includes stone grains 9 and iron sulfur packing layer from bottom to top; the sulfur iron packing layer includes sulfur particles 10 and iron packing layer, and the iron packing layer is provided with a support layer 12 up and down, and a screen is set in the middle, Water distribution holes 11 are provided in the support layer 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com