Method for preparing glazed tile from biomass fiber-epoxy resin composite material

A technology of biomass fiber and epoxy resin, which is applied in the direction of clay products, applications, household appliances, etc., can solve the problems of no significant improvement in the preparation method, poor use stability, poor compatibility, etc., and achieve improved performance and competitiveness, enhance the effect of action, increase the effect of swelling degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

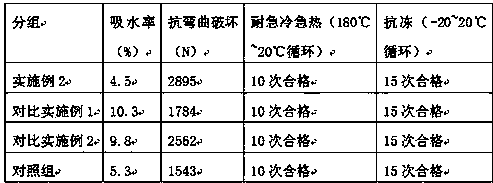

Examples

Embodiment 1

[0032] A kind of biomass fiber-epoxy resin composite material prepares the method for glazed tile, comprises the steps:

[0033] (1) Preparation of grouting blank:

[0034] a. Immerse the bamboo pulp fibers in the treatment solution A, then heat the treatment solution A immersed in the bamboo pulp fibers in a water bath, place it in a low-temperature environment immediately after the water bath heating, and leave it for 30 minutes to centrifuge, discard the supernatant, and use a purification After the water was centrifuged and washed 3 times, the precipitate was taken out and dried for later use;

[0035] b. Put the bamboo pulp fiber and epoxy resin powder after the treatment liquid A in operation a into the bead mill for grinding treatment according to the weight ratio of 8:1, and put them in the electron beam irradiation device for irradiation after completion After processing, take out the mixed powder for later use;

[0036] c. Put the mixed powder obtained in operation...

Embodiment 2

[0056] A kind of biomass fiber-epoxy resin composite material prepares the method for glazed tile, comprises the steps:

[0057] (1) Preparation of grouting blank:

[0058] a. Immerse the bamboo pulp fiber in the treatment solution A, then carry out the treatment solution A soaked with the bamboo pulp fiber in a water bath heat treatment, place it in a low temperature environment immediately after the water bath heating and let it stand for 35min and then centrifuge, discard the supernatant, and use a purification After the water was centrifuged and washed 3 times, the precipitate was taken out and dried for later use;

[0059] b. Put the bamboo pulp fiber and epoxy resin powder after the treatment liquid A of operation a into the bead mill for grinding treatment according to the weight ratio of 9:1.15, and then put them in the electron beam irradiation device for irradiation after completion After processing, take out the mixed powder for later use;

[0060] c. Put the mixe...

Embodiment 3

[0080] A kind of biomass fiber-epoxy resin composite material prepares the method for glazed tile, comprises the steps:

[0081] (1) Preparation of grouting blank:

[0082] a. Immerse the bamboo pulp fiber in the treatment solution A, then carry out the treatment solution A soaked with the bamboo pulp fiber in a water bath heat treatment, place it in a low temperature environment immediately after the water bath heating and let it stand for 40min and then centrifuge, discard the supernatant, and use a purification After the water was centrifuged for 4 times, the precipitate was taken out and dried for later use;

[0083] b. Put the bamboo pulp fiber and epoxy resin powder processed by the treatment solution A in operation a into the bead mill for grinding treatment according to the weight ratio of 10:1.3, and place them in the electron beam irradiation device for irradiation after completion After processing, take out the mixed powder for later use;

[0084] c. Put the mixed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com