Utilizing method for utilizing tailings containing silver, lead and zinc to extract silver and waste slag of tailings containing silver, lead and zinc

A tailings slag, lead-zinc technology, applied in the field of environmental protection, energy saving, and new material technology, can solve the problems of residual flotation agents, groundwater pollution, toxicity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in detail below in conjunction with specific embodiments. The main metal content is copper, lead 0.15 grams ton, zinc 0.14 grams ton, sulfur, silver

[0014] step 1:

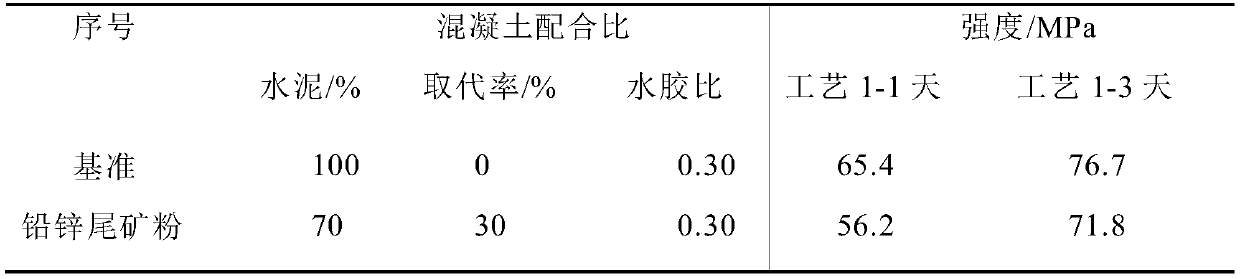

[0015] The metal content of the raw materials is shown in Table 1.

[0016] Table 1 Metal content of raw materials, unit: gram ton

[0017] copper 0.02 lead 0.15 zinc 0.14 sulfur 3 silver 35

[0018] The silver content in lead-zinc cyanide tailings is high and can be extracted and recovered. Grind the lead-zinc cyanide tailings to 200 mesh.

[0019] Step 2 Recovery / extraction of silver from cyanide tailings using wet leaching

[0020] Using the wet leaching method, varying amounts of Ag(CN)- 2 with Ag + . CN-At this time, use the molar method to measure and obtain the analysis results, and calculate the amount of silver salts such as silver nitrate added according to the results. After adding silver salts such as silver...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com