Composite axle-mounted brake discs for high-speed trains

A composite material, high-speed train technology, applied in the direction of brake discs, brake types, brake components, etc., can solve the problems of poor toughness, casting molding, easy brittle cracking, etc., to improve service life, reduce unsprung weight, large The effect of braking energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

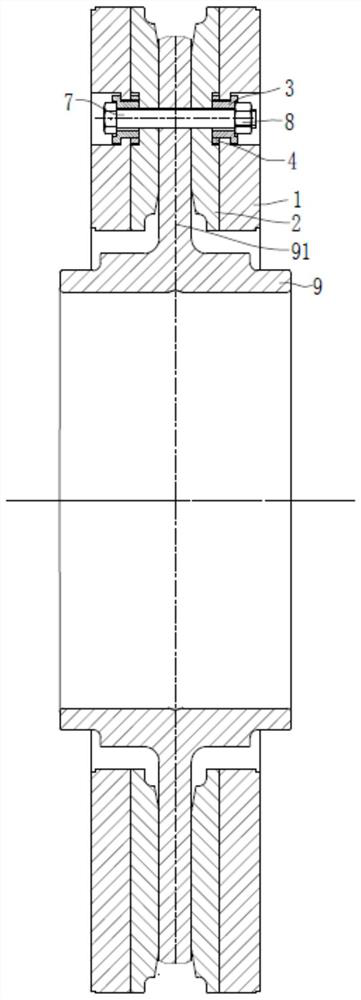

[0039] refer to figure 1 , a high-speed train composite shaft-mounted brake disc, including a flange hub 9, two steel skeletons 2 and two carbon-ceramic friction rings 1; where:

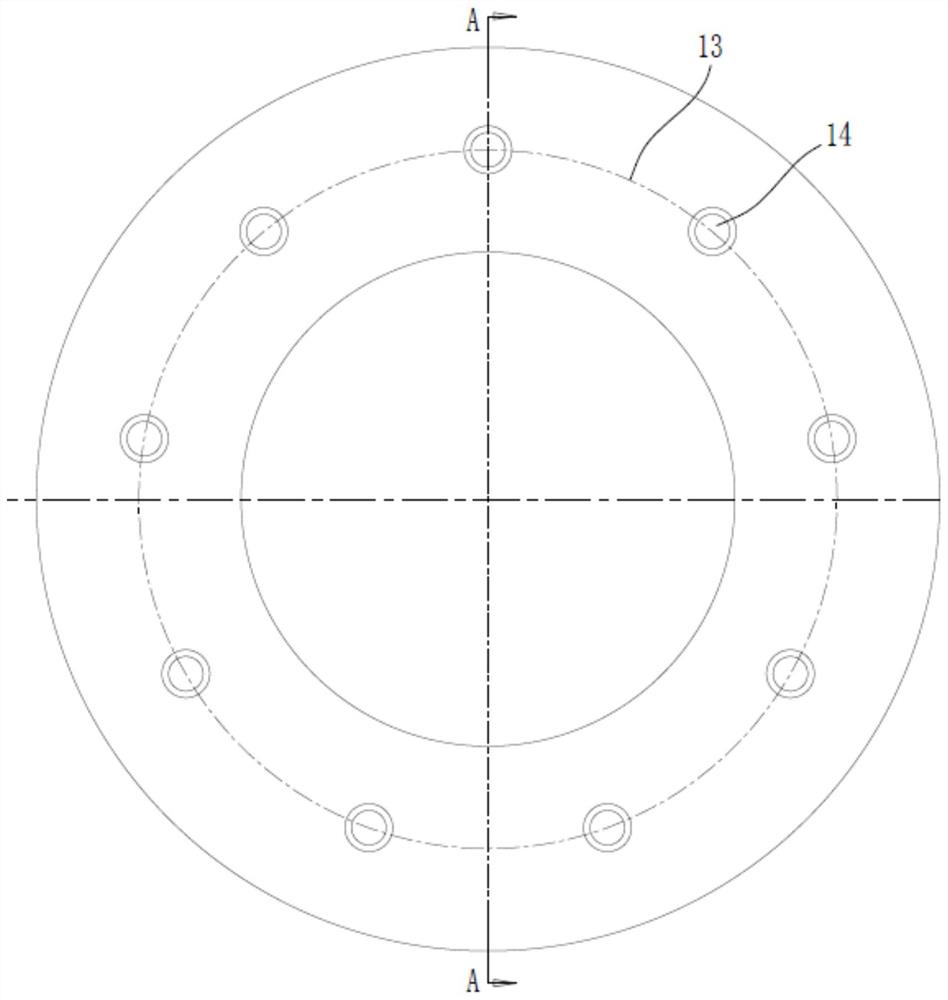

[0040] Flange hub 9, used to be fixedly connected with the axle (not shown in the figure), refer to Figure 11 , 9 flange hub bolt holes 92 and 3 positioning pin holes 94 are evenly distributed on the flange hub web 91; the flange hub bolt holes 92 are evenly arranged at intervals of 40°; the alignment pin holes 94 are evenly arranged at intervals of 120° ; Adjacent flange hub bolt holes 92 and positioning pin holes 94 are arranged at intervals of 20°;

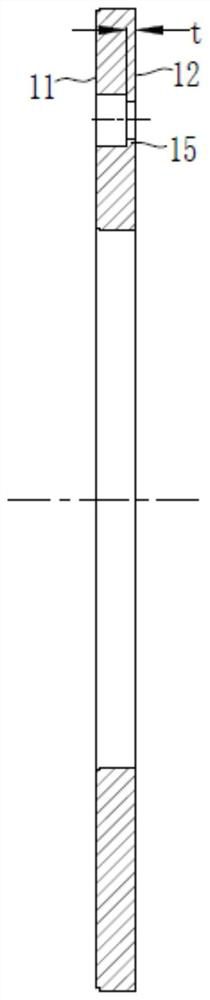

[0041] Two pieces of steel frame 2 are installed on both sides of the flange hub 9 respectively, refer to Figure 4 and Figure 5 , the steel skeleton 2 is a ring with a heat dissipation rib structure, and the material is cast steel or forged steel, and the planes on both sides are the slider chute surface 21 and the heat dissipation rib surface 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com